centrifugal slurry pump vertical factories

Latest articles

As the slurry is collected at the bottom of the tower, more rubber lined pumps are required to transfer the slurry to storage tanks, tailings ponds, waste treatment facilities or filter presses. Depending on the type of FGD process, other pump models are available for slurry discharge, pre-scrubber recovery and catch basin applications.

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read MoreChoosing Dry Slurry Pumps Versus Submersible Slurry Pumps

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read MoreTypes of slurry pump installation.

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read More>Slurry Pump

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read MoreWY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read MoreLight-duty Slurry Pump

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read MoreRubber lined pumps offer many advantages

centrifugal slurry pump vertical factories...

centrifugal slurry pump vertical factories 【centrifugal slurry pump vertical factories】

Read More

Popular articles

- Slurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

- how-does-a-dredge-pump-work

- - Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

- Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Corrosiveness of the slurry

Latest articles

-

Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

-

Slurry pump power adjustment

-

Slurry pump design

-

Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

-

The Company Adopts Advanced Computer Aided Engineering Software

-

The Company Adopts Advanced Computer Aided Engineering Software

Links

- Another benefit of FRP vessels is their low maintenance requirements. Unlike steel vessels that require regular painting and protective coatings to prevent corrosion, FRP vessels are virtually maintenance-free. This reduces the long-term costs associated with upkeep and prolongs the lifespan of the vessel, making them a cost-effective alternative to traditional materials.

The smooth surface of FRP equipment reduces the risk of splinters and sharp edges, providing a safer playing environment for children The smooth surface of FRP equipment reduces the risk of splinters and sharp edges, providing a safer playing environment for children

The smooth surface of FRP equipment reduces the risk of splinters and sharp edges, providing a safer playing environment for children The smooth surface of FRP equipment reduces the risk of splinters and sharp edges, providing a safer playing environment for children frp playground equipment.

frp playground equipment.

This is another important measure of Sinochem International’s layout in the new materials industry, according to Sinochem International. The two sides will use this joint laboratory as a platform for comprehensive cooperation in the field of high-performance composites R&D, and jointly promote the development of advanced composite materials technology in China.

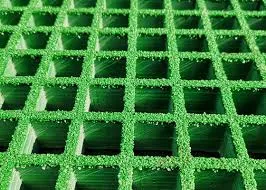

FRP gratings are commonly molded using high-strength fiberglass reinforcement materials along with resin and other additive agents to enhance product quality. Molded FRP gratings find widespread use across various industrial sectors such as power generation, waste processing, oil refining, mining, and more. Additionally, these gratings are increasingly utilized in commercial settings as interior and exterior materials, including drainage systems, fencing, building facades, ceilings, and others.

They facilitate the creation of holes for anchoring, installing pipes, or setting explosives in mining operations They facilitate the creation of holes for anchoring, installing pipes, or setting explosives in mining operations

They facilitate the creation of holes for anchoring, installing pipes, or setting explosives in mining operations They facilitate the creation of holes for anchoring, installing pipes, or setting explosives in mining operations pneumatic drill bit. In mining, their power and efficiency enable workers to excavate through solid rock, significantly increasing productivity.

pneumatic drill bit. In mining, their power and efficiency enable workers to excavate through solid rock, significantly increasing productivity.All of these benefits help it be a safer material option for various construction projects, especially for environments that are already a bit hazardous for workers.

Gratings & Covers

FRP vessels can be molded into almost any shape or size, making them suitable for a wide range of applications from small storage tanks to large pressure vessels FRP vessels can be molded into almost any shape or size, making them suitable for a wide range of applications from small storage tanks to large pressure vessels

FRP vessels can be molded into almost any shape or size, making them suitable for a wide range of applications from small storage tanks to large pressure vessels FRP vessels can be molded into almost any shape or size, making them suitable for a wide range of applications from small storage tanks to large pressure vessels frp vessel. This flexibility also allows for the integration of additional features such as baffles, nozzles, and access ports, further enhancing the functionality of FRP vessels.

frp vessel. This flexibility also allows for the integration of additional features such as baffles, nozzles, and access ports, further enhancing the functionality of FRP vessels.This type of grating is commonly used for offshore installations or on ships. It can be safely submerged in water and will not become damaged or corroded by salt water.

yt29a. Cryptography plays a vital role in securing digital transactions, protecting sensitive data, and ensuring privacy in the digital age. By encoding information with a specific algorithm like YT29A, data becomes unreadable to unauthorized parties, safeguarding it from potential breaches.

yt29a. Cryptography plays a vital role in securing digital transactions, protecting sensitive data, and ensuring privacy in the digital age. By encoding information with a specific algorithm like YT29A, data becomes unreadable to unauthorized parties, safeguarding it from potential breaches.