high quality oem froth pump manufacturers

Latest articles

The terms flushing and quench, often seem to be confused or misused when discussing seal support schemes for , slurry pumps, . As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read MoreApplications of Rubber Lined Slurry Pumps

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read More- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read MoreWY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read MoreSlurry Pump

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read MoreA clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

high quality oem froth pump manufacturers...

high quality oem froth pump manufacturers 【high quality oem froth pump manufacturers】

Read More

Popular articles

- BCT Ceramic Slurry Pumps

- What is the pump constructed of?

- >Dredge Pump

- What is the best seal arrangement for the application?

- The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

- Slurry Pump

Latest articles

-

Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

-

Choosing the Right Pump for Flue Gas Desulphurisation

-

Pumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

-

If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

-

target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

-

Corrosiveness of the slurry

Links

Quality Assurance

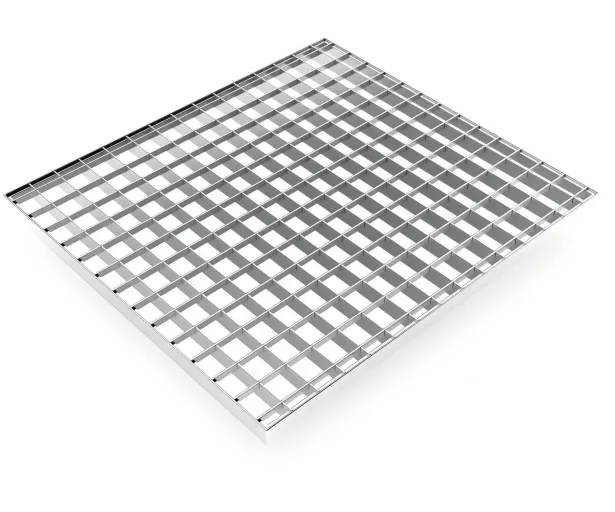

One of the key benefits of mesh grating flooring is its exceptional strength-to-weight ratio. This characteristic makes it suitable for heavy-duty applications, such as in warehouses, factories, and industrial facilities where heavy loads are common. The open design of mesh grating allows for easy passage of fluids and debris, minimizing the risk of slips and falls, thereby ensuring a safer working environment.

Stahlgitterroste sind eine praktische und vielseitige Lösung für viele Bau- und Ingenieuranwendungen. Die verfügbaren Größen und Typen ermöglichen es, für jede Anforderung die richtige Lösung zu finden. Ob in der Industrie oder im öffentlichen Raum, Stahlgitterroste bieten Sicherheit, Haltbarkeit und Funktionalität.

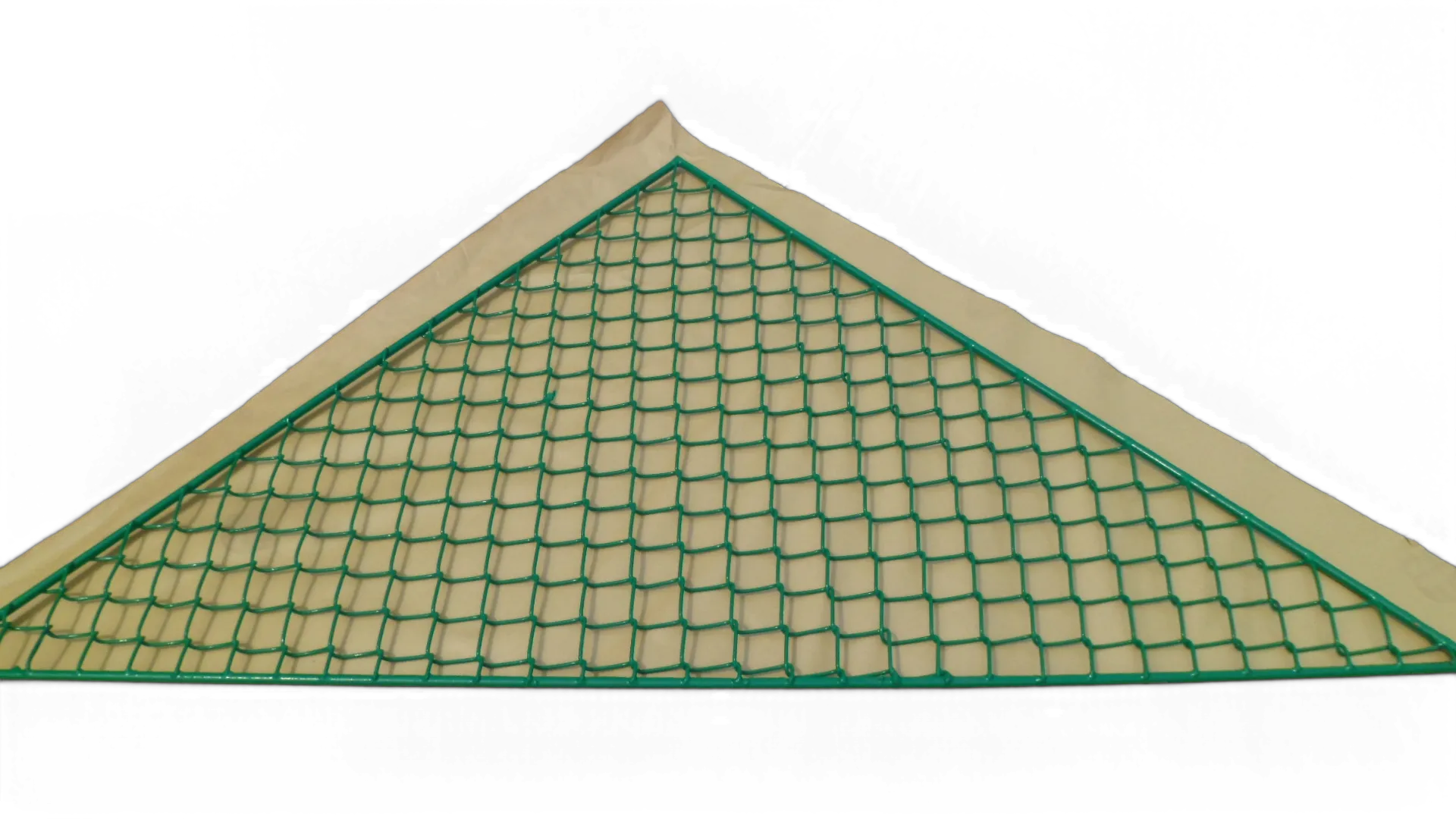

Pre-tensioned Screens: Pre-tensioned screens are designed to maintain their tension and shape during operation. This design enhances their durability and extends their lifespan.

1. วัสดุ กรองระบายน้ำทิ้งมักทำจากวัสดุที่หลากหลาย เช่น เหล็กกล้า สแตนเลส หรือพลาสติก แต่ละวัสดุมีข้อดีและข้อเสียที่แตกต่างกัน เช่น เหล็กกล้าอาจมีความทนทานสูง แต่สามารถเป็นสนิมได้หากไม่ได้รับการดูแล ในขณะที่พลาสติกมีน้ำหนักเบาและไม่เป็นสนิม แต่ความแข็งแรงอาจไม่เท่ากับเหล็ก

replacement trench drain grates

Le treillis en acier 19W4 est un produit de construction très apprécié pour ses caractéristiques structurelles et sa polyvalence. Utilisé dans une variété d'applications industrielles, commerciales et résidentielles, ce type de treillis est notamment connu pour sa robustesse, sa légèreté et sa résistance à la corrosion.

Negli ultimi anni, la tecnologia delle griglie leggere (lightweight grating) ha guadagnato sempre più attenzione nel campo dell'ingegneria e del design. Questi dispositivi, caratterizzati da una struttura sottile e leggera, offrono molteplici vantaggi rispetto ai materiali tradizionali, rendendoli ideali per una vasta gamma di applicazioni.

Shaker screens are available in various types, each designed to meet specific operational requirements and address different challenges encountered during drilling operations. The most common types of shaker screens include: