china 4x3dd slurry pump

Latest articles

Slurry pump power adjustment

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read MoreMetal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read MoreHow to choose a slurry pump?

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read More- Pumping the final product in a process

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read MoreA slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read MoreIf you have experience pumping slurries, you know it's not an easy task. Slurries are heavy and difficult to pump. They cause excessive wear on pumps and their components and are known to clog suction and discharge lines if not moving fast enough. Most importantly, it’s a challenge to make slurry pumps last for a reasonable amount of time. But, there are a few things you can do to extend the life of your slurry pump and make pumping slurry less of a challenge.

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read MoreMixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read MoreConsider the impeller. Slurry pumps must have thicker vanes than water pumps to prevent wear. Due to the increased thickness, there will be fewer vanes, otherwise the passages will be too narrow and will affect the performance of the pump. The impeller should have a large enough passage so that the largest solid particles can pass through without clogging.

china 4x3dd slurry pump...

china 4x3dd slurry pump 【china 4x3dd slurry pump】

Read More

Popular articles

- I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

- Hydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

- Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

- Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

- Applications of Rubber Lined Slurry Pumps

- TL FGD Pump

Latest articles

-

>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

-

Is the discharge configuration suitable for abrasive slurries?

-

Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal , slurry pump, . Lets talk about how slurry pumps differ from standard pumps and how to narrow your choices.

-

- Low noise level - Operating underwater results in low noise or even silent operation.

-

Types of damage to slurry pumps

-

Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

Links

- In the realm of electrical engineering and construction, safety is paramount. One innovative solution that has emerged to mitigate risks associated with electrical hazards is the Arc Proof Tape. This specialized tape, designed to withstand arc flash incidents, has become a game-changer in the industry, ensuring worker protection and enhancing operational efficiency.

- Overall, colored PVC tape is a versatile and handy tool that can be used in a variety of industries and applications. Its durable construction, vibrant colors, and adhesive properties make it a valuable addition to any toolkit. Whether for marking, labeling, crafting, automotive work, or event planning, colored PVC tape is a practical and cost-effective solution for a wide range of needs.

Welcome to the world of control boxes, the unsung heroes behind the seamless operation of myriad electrical systems.

flex tape white 8 x 5. It can be easily cut to size with scissors or a knife, making it simple to customize for any application. It can also be applied quickly and easily, requiring no special tools or equipment. This makes it a convenient and efficient solution for DIY projects and emergency repairs.

Conclusion

When it comes to adhesive tape, knowing the different types of adhesives is an essential step in choosing the right tape for you. Not all adhesives are created equal. Some tape adhesives are easy release, some have extra-strong grip, and some are designed to withstand outdoor usage. All are useful in their proper context, but you need to have the right tape for the right job. You wouldn't, for instance, want to use a painter's tape with a weak adhesive on a heavy-duty industrial project.

J50 High-voltage EPR Rubber Tape

weatherstrip seal. By preventing water ingress, they help avoid damage from moisture, mold, and mildew, which can lead to costly repairs and potential health hazards. They also act as a shield against insects and other small pests, ensuring a cleaner and more hygienic living space.

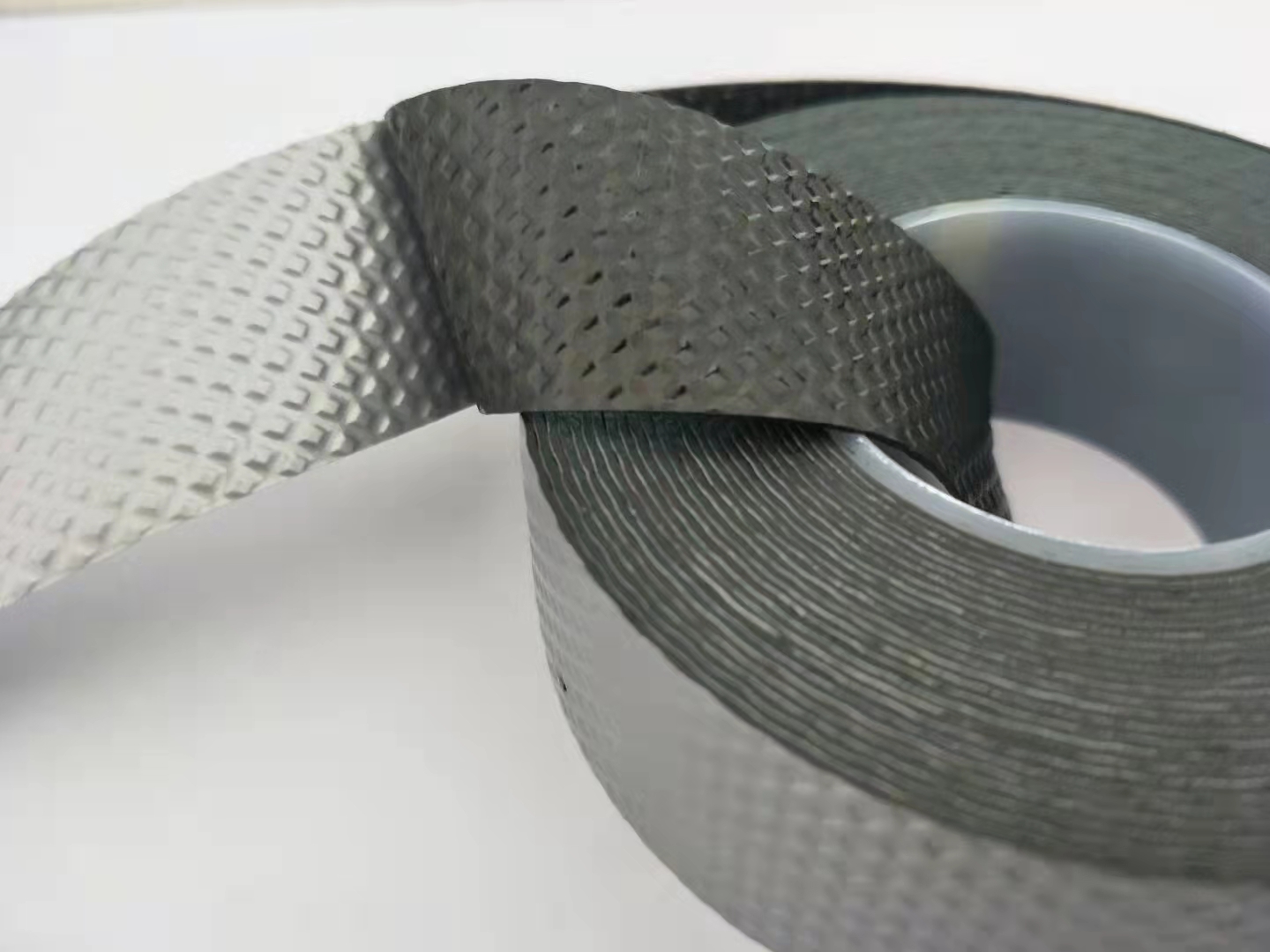

weatherstrip seal. By preventing water ingress, they help avoid damage from moisture, mold, and mildew, which can lead to costly repairs and potential health hazards. They also act as a shield against insects and other small pests, ensuring a cleaner and more hygienic living space.Rubber tapes are an essential component in many industries, including construction, automotive, and electrical fields. These tapes are made from different types of rubber and used for various applications, such as sealing, insulation, and packaging. Here are some of the most commonly used rubber tapes:

1. Silicone Rubber Tape: This type of rubber tape is highly resistant to heat, cold, and moisture, which makes it ideal for electrical and electronic applications. It can also be used for sealing and insulating.

2. Butyl Rubber Tape: Butyl rubber tape is known for its high adhesive strength and excellent sealing properties. It is often used in the construction industry for sealing roofs, windows, and doors.

3. EPDM Rubber Tape: EPDM (ethylene propylene diene monomer) rubber tape is highly resistant to UV radiation and weathering, which makes it ideal for outdoor applications. It is often used for sealing or protecting joints, roofs, and facades.

Polyethylene Tape offers a certain degree of water resistance, but it is not entirely waterproof. Polyethylene is a thermoplastic polymer known for its resistance to moisture and water absorption. Therefore, Polyethylene Tape can provide a barrier against water and offer some protection in applications where exposure to moisture is a concern.

safety floor tape. In high-risk areas where special precautions are necessary, safety floor tape can be used to clearly mark off these areas and prevent unauthorized access.

The PLC outputs will be attached to a bank of relays, which will close an internal contact, allowing electricity to be sent out to toggle on or off a device on the manufacturing line. Contactors are used to drive motors, whereas relays control devices such as lights and fans.

5. Chemical Resistance

As we’ve navigated through the intricacies of control boxes, it’s clear they are more than just containers; they are the nerve centers of any electrical system.

Repairing leaking pipes and pipe joints

Selecting the Right Control Box for Your Needs

Polyethylene film tape (6350X) is a 5.5-mil thick tape with acrylic rubber adhesive. This film tape is flexible, conformable, durable, and chemical resistant. It is also resistant to tears, punctures, and abrasions, which makes it a good protective tape. It is also a good barrier tape for gas and moisture-proofing. Taping with polyethylene film tape produces a permanent bond with no edge bleeding.

Quantity: Supplied in single rolls