china 8/6 rubber slurry pump factory

Latest articles

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read MoreTypical Applications of slurry pump

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read MoreIt is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read MoreThese conditions include

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read MoreSlurry pump design

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read MoreThe main objective of all flush water programmes is to prevent contamination of the seals by pumped water.The flush water programme for boxes is therefore very similar to the flush water programme for mechanically sealed boxes. However there are still some obvious mechanical differences. The most notable difference is the addition of a seal (packing) between the inlet and outlet limits. This minimises the amount of flushing fluid consumed.

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read MoreAgain, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read MoreSlurry Pump

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read MoreTypes of slurry pumps

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

china 8/6 rubber slurry pump factory...

china 8/6 rubber slurry pump factory 【china 8/6 rubber slurry pump factory】

Read More

Popular articles

- In AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

- Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

- >Slurry Pump vs Mud Pump

- There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- Vertical Slurry Pump

- Slurry pump vs mud pump

Latest articles

-

What is 'slurry'?

-

Discharge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

-

Step 1

-

If centrifugal, are the impellers of the right design and material?

-

For more information about this new and improved pump, please contact us.

-

Slurry Pump

Links

- Beyond its practical applications, car loom tape also contributes to the aesthetics of the vehicle

- Chemical Resistance – Polyester offers good resistance to many chemicals, solvents, and oils. It can withstand exposure to a wide range of chemicals without significant degradation, making it suitable for applications in harsh chemical environments.

- Butyl foil tape, a seemingly humble material, is a powerful and versatile solution in a myriad of industrial applications. This unique tape is a composite of a butyl rubber adhesive and a metallic foil backing, offering exceptional performance characteristics that make it indispensable in various sectors.

You’ll find control boxes in nearly every industry around the world, from the boxes that control heavy industrial equipment to DIY project boxes. Each type of control box has its own requirements and idiosyncrasies, and each demands careful attention to best practices of design.

What Exactly Is a Control Box?

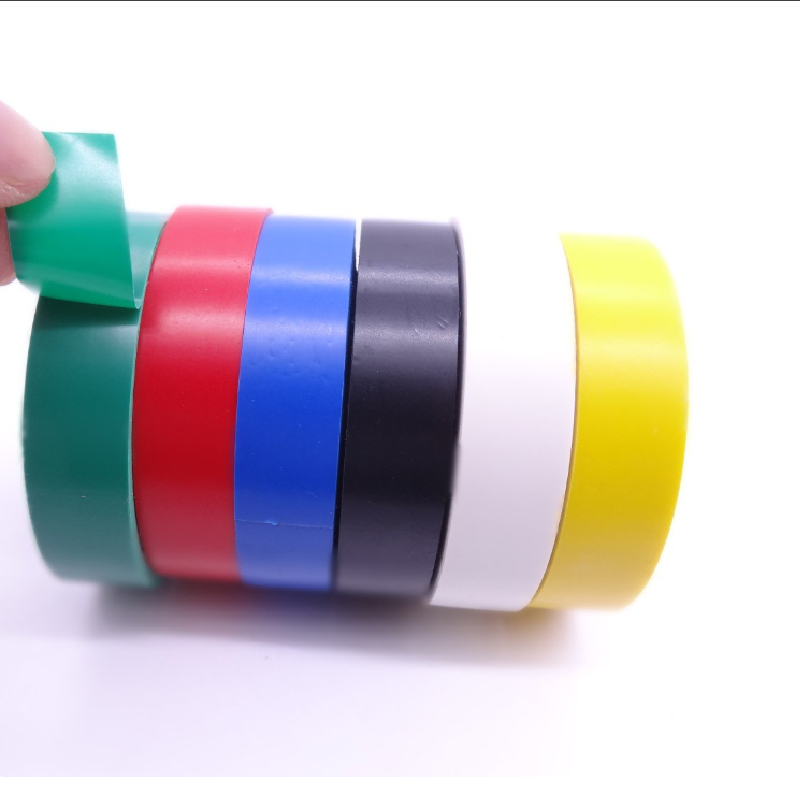

rubber electrical insulation tape. It can be easily wrapped around wires and connections of various shapes and sizes, conforming to the contours of the components for a secure and reliable fit. This flexibility makes it a preferred choice for electricians and technicians working on a wide range of electrical projects.

In our modern world, where safety and material integrity are paramount, flame retardant tapes have emerged as a crucial component across various industries. These specialized tapes are designed to withstand high temperatures and inhibit the spread of flames, making them an essential tool in improving fire safety and enhancing the durability of materials.

self amalgamating tape 50mm. Available in various materials like rubber, silicone, or polyethylene, it caters to different requirements. For example, rubber tape is ideal for plumbing and gas works due to its water resistance, while silicone tape excels in high-temperature environments typical of automotive and industrial settings.

self amalgamating tape 50mm. Available in various materials like rubber, silicone, or polyethylene, it caters to different requirements. For example, rubber tape is ideal for plumbing and gas works due to its water resistance, while silicone tape excels in high-temperature environments typical of automotive and industrial settings.Can Electrical Tape Catch Fire?

Fire seal tape is a critical yet often underappreciated component in the realm of fire safety and construction. Its ability to seal gaps effectively, enhance fire resistance, and ensure compliance with safety regulations makes it indispensable in modern building practices. As the construction industry continues to prioritize safety and efficiency, the correct use of fire seal tape will remain a key factor in protecting lives and properties from the devastating effects of fire. Investing in quality fire seal tape and ensuring its proper installation is a responsible choice for builders, architects, and property owners alike.

Prepare the Surface: Ensure the surface you're applying the tape to is clean and dry. This will help the tape adhere properly.