high quality 12 inch slurry pump

Latest articles

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read MoreSump drainage or washdown

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read More>Slurry Pump

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read MoreUsing rubber as a wear lining material means

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read MoreUsing rubber as a wear lining material means

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read MoreThe discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read MoreFor example.

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read MoreIn harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read MoreSlurry pump considerations

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read MoreRubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

high quality 12 inch slurry pump...

high quality 12 inch slurry pump 【high quality 12 inch slurry pump】

Read More

Popular articles

- How to choose a slurry pump?

- Corrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

- Centrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

- Slurry Pump selection

- Determine the nature of the material to be pumped

- AIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

Latest articles

-

Horizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

-

There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

-

There is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

-

1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

-

A slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

-

For more information about this new and improved pump, please contact us.

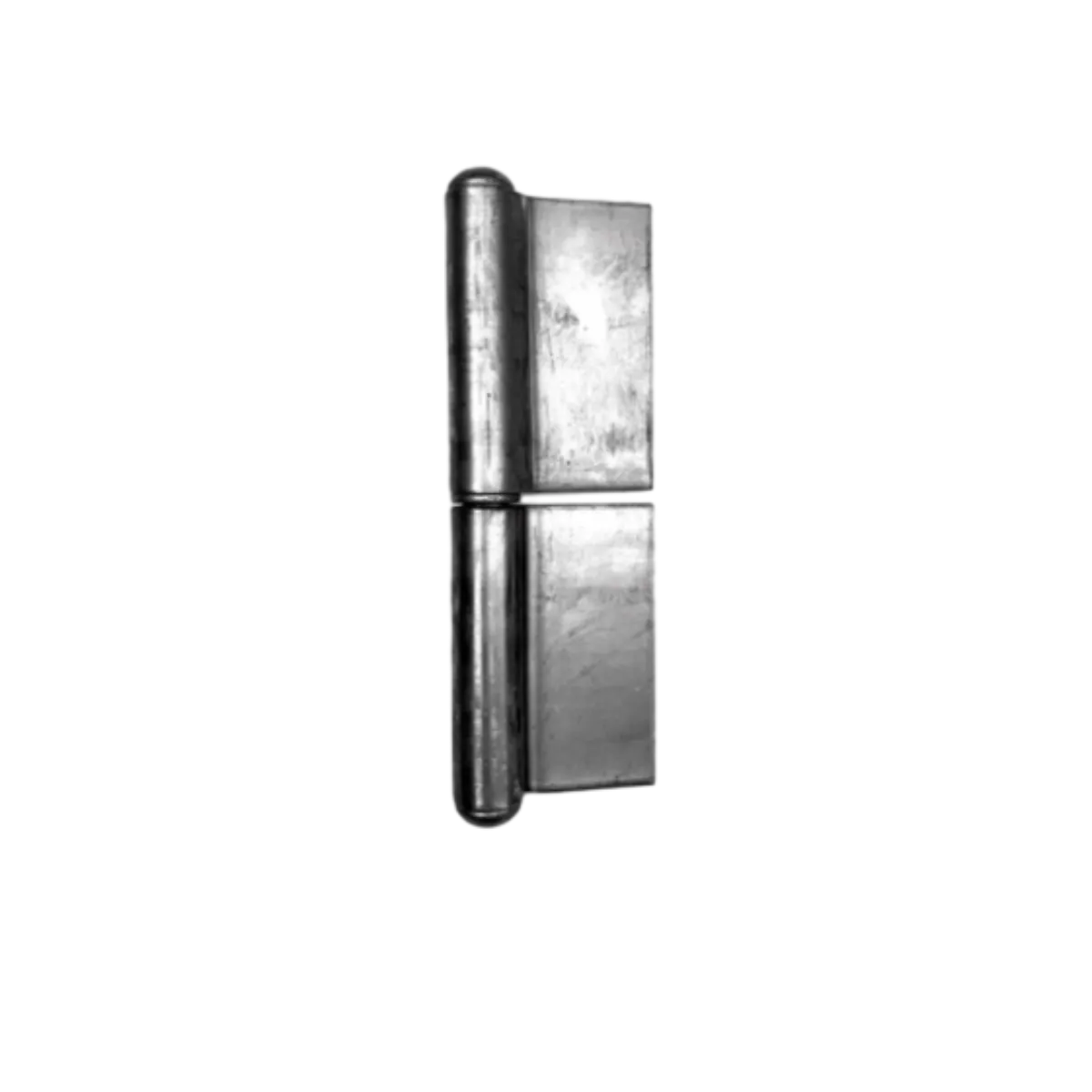

Our Forged Steel products are expertly crafted to offer both durability and style, making them a timeless addition to any setting. The Cast Iron elements in our collection exude a classic, vintage charm, while our Aluminum pieces offer a lightweight and versatile option for a modern touch.

Frequently Asked Questions

sliding window roller wheel. By providing a tight seal when closed, they help prevent air leakage, thereby maintaining indoor temperature and reducing energy consumption for heating or cooling. This not only benefits the environment but also translates into cost savings for homeowners.

sliding window roller wheel. By providing a tight seal when closed, they help prevent air leakage, thereby maintaining indoor temperature and reducing energy consumption for heating or cooling. This not only benefits the environment but also translates into cost savings for homeowners.Types of Sliding Door Runner Wheels

Thermal break profiles

metal cash box with lock. From important documents and jewelry to keys and electronic devices, these boxes provide a convenient and secure storage solution for all your valuables.

steel main gate handle design. The handle must be securely attached to the gate to prevent accidents and ensure long-term durability. It is essential to enlist the help of professionals to ensure proper installation and alignment of the handle.