high quality marine dredge pump factories

Latest articles

Safety

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read MoreMake sure you follow the basic rules of pump piping.

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read MoreCustomised pumps

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read More- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read MoreTo find out more about Aier slurry Pumps, please >contact us.

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read MoreSlurry Pump VS Mud Pump

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read MoreWhen dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read MoreEspecially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

high quality marine dredge pump factories...

high quality marine dredge pump factories 【high quality marine dredge pump factories】

Read More

Popular articles

- Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

- When pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

- Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

- Follow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

- Advantages of rubber

- Slurry Pump

Latest articles

-

Slurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

-

Series of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

-

TL FGD Pump

-

Many types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

-

Slurry Pump VS Mud Pump

-

Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

Links

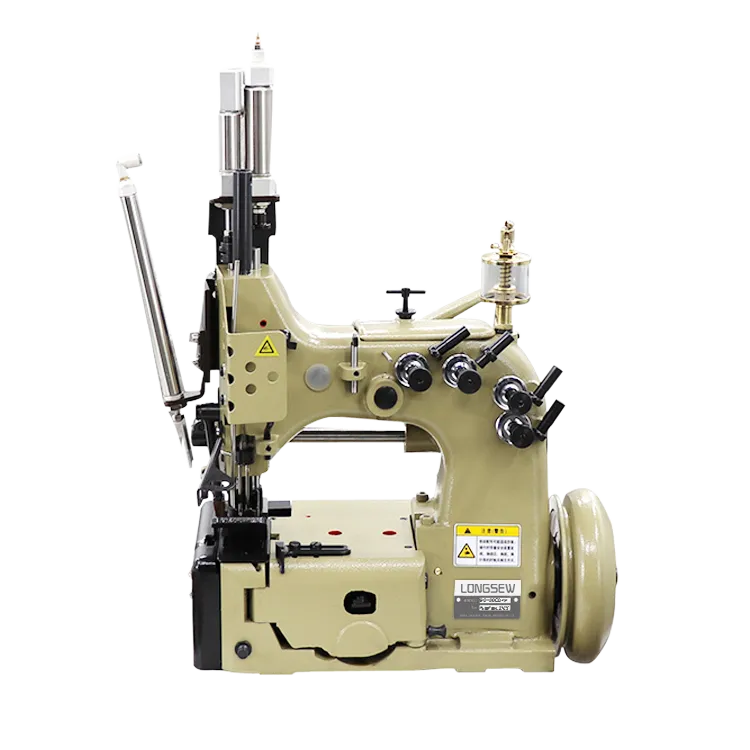

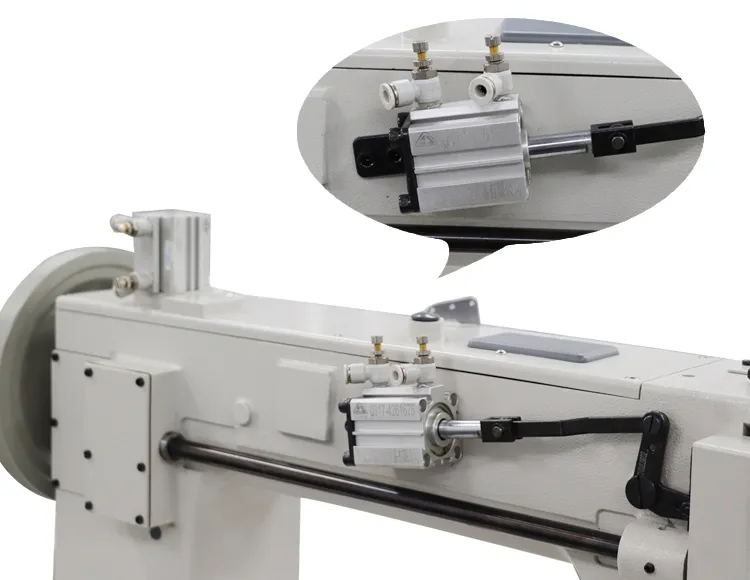

So whether you are a beginner looking to get started in the world of sewing or a seasoned pro looking to upgrade your equipment, take advantage of the sewing machine specials that are currently available and treat yourself to a new machine that will take your sewing skills to new heights. With deals and discounts on popular brands and models, there has never been a better time to invest in a sewing machine that will help you unleash your creativity and bring your sewing projects to life.