centrifugal wastewater pump factory

Latest articles

A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read MoreTraditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read Morehow-does-a-dredge-pump-work

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read MoreOur firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read MoreDredge Pump

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read MoreSubmersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read MoreHydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read More>Slurry Pump vs Mud Pump

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read MoreThe concentration of solids in the slurry - measured as a percentage of the total volume.

centrifugal wastewater pump factory...

centrifugal wastewater pump factory 【centrifugal wastewater pump factory】

Read More

Popular articles

- Includes a large number of solids or particles.

- Corrosiveness of the slurry

- All products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

- Mill sump

- Underwater installation

- Aier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

Latest articles

-

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

-

The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

-

Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

-

Slurry Pump

-

The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

Links

1. Color Coding One of the most significant benefits of red insulation tape is its color. In many industries, colors have specific meanings, and red often signifies a warning or alert. Using red insulation tape to mark wires can help other workers quickly identify potential hazards, ensuring safety in the workplace.

4. Healthcare Facilities Hospitals and clinics can benefit from using this tape to mark restricted areas or pathways that need to remain clear for emergency access. It can also guide patients and visitors through complex layouts, reducing confusion and promoting efficiency.

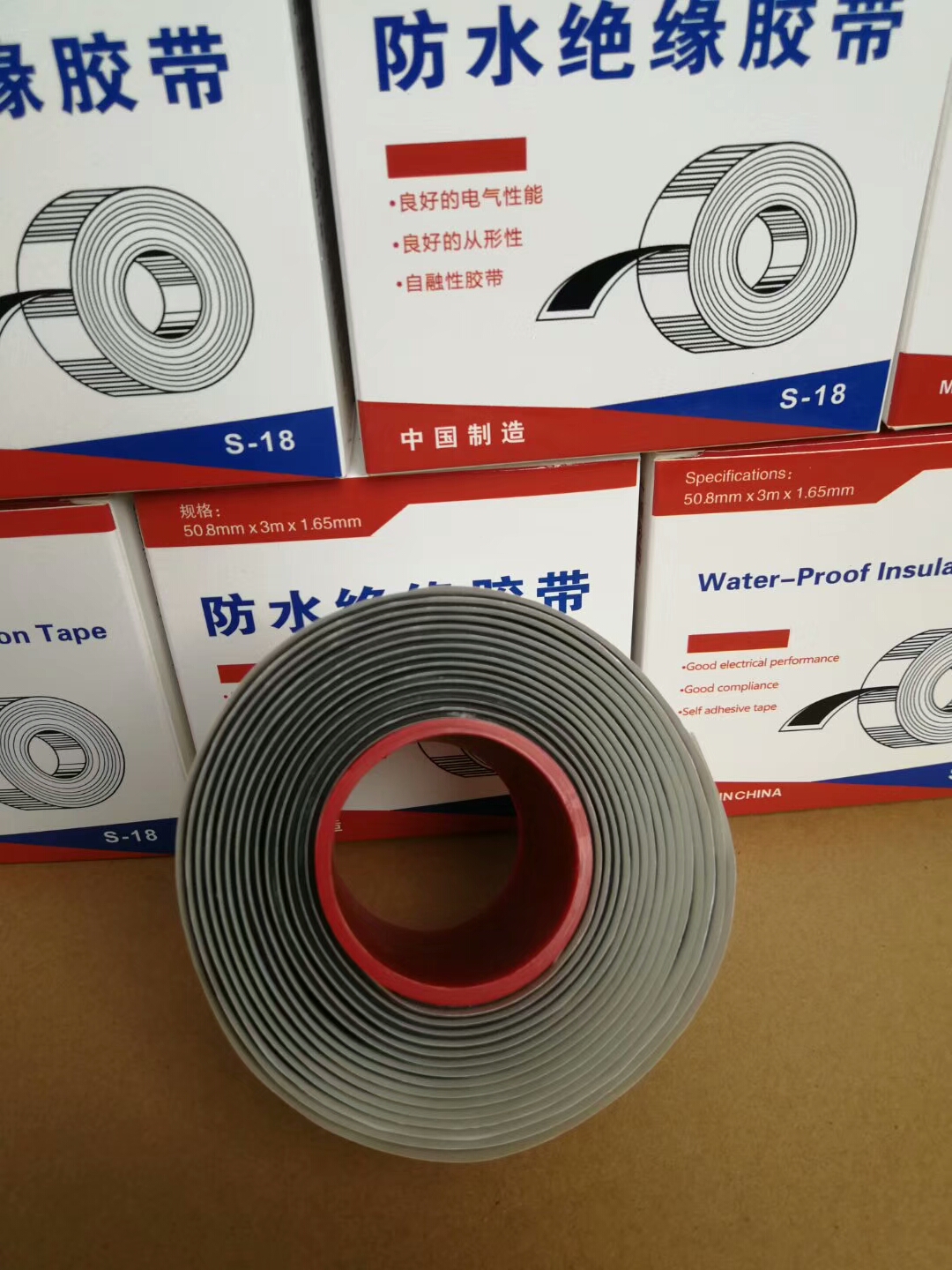

Applications for Butyl Rubber Sealant Tape

Conclusion: The Central Hub of Your Electrical System

(3) Even if it is wound around sharp complex shapes, it is still well sealed, waterproof, uniform and smooth, and can still maintain high insulation performance in high humidity environment;

Gradually, I began to weave my own thoughts and feelings into the music, creating a tapestry of sound and emotion that was uniquely mine Gradually, I began to weave my own thoughts and feelings into the music, creating a tapestry of sound and emotion that was uniquely mine

Gradually, I began to weave my own thoughts and feelings into the music, creating a tapestry of sound and emotion that was uniquely mine Gradually, I began to weave my own thoughts and feelings into the music, creating a tapestry of sound and emotion that was uniquely mine diall self amalgamating tape.

diall self amalgamating tape.

gray electrical tape.