froth centrifugal slurry pump manufacturer

Latest articles

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read More>Dredge Pump

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read MoreThere is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read MoreTypes of damage to slurry pumps

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read Morefactors-to-consider-when-choosing-a-slurry-pump

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read MoreThe FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read MoreHigh head (i.e. the height to which the pump can move the liquid)

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read MoreHigh head (i.e. the height to which the pump can move the liquid)

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read MorePacking the box seal

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read MoreWhat is Heavy Duty Slurry Pump?

froth centrifugal slurry pump manufacturer...

froth centrifugal slurry pump manufacturer 【froth centrifugal slurry pump manufacturer】

Read More

Popular articles

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

- What is a slurry?

- Dredge Pump

- It is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

- With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

- Slurry Pump

Latest articles

-

The size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

-

A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

-

Magnetite mixing

-

To reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

-

The first major requirement for >slurry pumps is to provide adequate service life. The erosive and corrosive effects of slurries, such as the impact of high velocity flow of liquid/solid mixtures, can be really challenging. In many applications, some of the solids in the mixture are larger than the particles normally specified; therefore, the pump should be able to pass through them without causing any damage or operational problems.

-

The Company Adopts Advanced Computer Aided Engineering Software

Links

Aluminum profiles for windows and doors have unparalleled advantages in their durability, energy efficiency and environmental protection, aesthetics, design flexibility and other aspects. It is believed that after people learn about the relevant characteristics of aluminum profiles for windows and doors through this article, they will be able to know a few more points about them, so that they can better choose the preferred aluminum profiles.

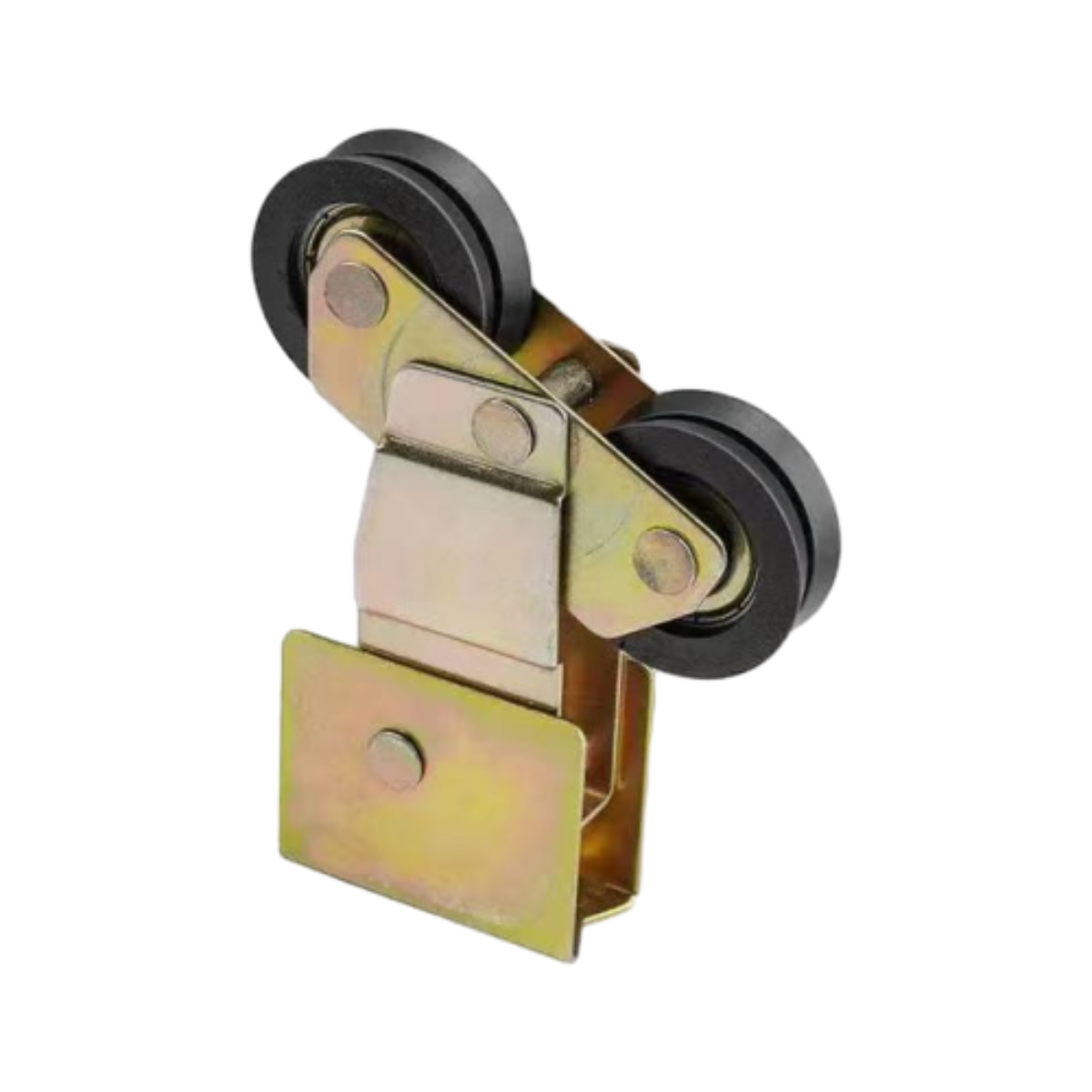

Aluminum profiles continue to be the preferred choice for high-performance, sustainable and aesthetically pleasing window and door solutions for residential, commercial and industrial applications.- Sliding doors, an epitome of modern convenience and sleek design, owe their smooth operation to a component that often goes unnoticed - the wheels. These humble mechanisms, hidden within the framework, play a pivotal role in the functionality of sliding doors, transforming a simple architectural element into a seamless blend of style and efficiency.

- The simplicity of the round bar pull handle lies in its clean lines and geometric form. Its circular silhouette adds a touch of sophistication, whether it's incorporated into traditional, modern, or even industrial designs. The smooth surface provides an easy grip, ensuring practicality without compromising style.

- Crafted from solid metal, the lock box is no mere trifle to be easily breached. Its walls are thick and unyielding, capable of withstanding not only the prying hands of would-be thieves but also the more sophisticated attacks of cutting tools and drills. The metal's density further ensures that any attempts at physical manipulation will be met with a resounding defiance, echoing throughout the chamber like a proclamation of its unassailability.

- When it comes to choosing the right steel security safe lock box, there are several factors to consider

- Another advantage of the steel lock box double is its compact size

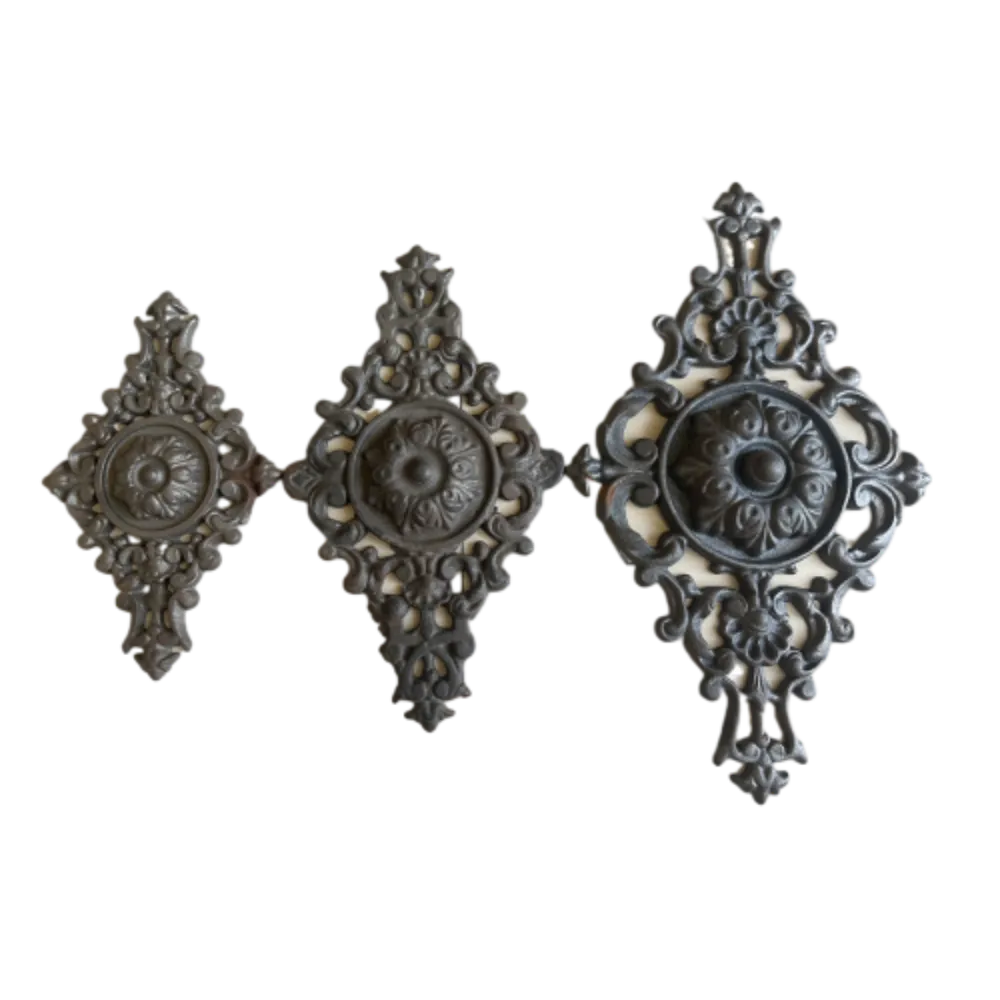

- Decorative iron castings, a testament to the enduring fusion of art and industry, have been an integral part of architectural design for centuries. These intricate, durable works of art, often forged from molten iron, bring a unique charm and character to both interior and exterior spaces.

- The key principle behind roller sliding window is to efficiently manage memory usage by only storing the elements within the current window. When the window reaches its maximum size, the oldest element is removed from the beginning of the sequence to make room for the newest element. This process ensures that the window always contains the most recent elements, making it suitable for real-time applications such as video streaming and online gaming.

- In the vast landscape of modern materials science, aluminum stands out for its unique properties, making it an indispensable component in a myriad of applications. Among these, the humble yet ingenious aluminum sliding wheel represents a testament to the metal's versatility and utility. Lightweight, durable, and possessing excellent corrosion resistance, these wheels have revolutionized everything from transportation to industrial automation.

- Pull handles, a simple yet essential element in furniture and door design, have been a staple in households and commercial spaces for centuries. Their functionality and aesthetic appeal make them a versatile solution for various applications.

Whether you’re considering having a wrought iron fence installed on your property or you’re maintaining an existing iron fence, you’ve probably run into fence components such as spires, posts, rails, and pickets. It’s a good idea to become familiar with these wrought iron fence components if you plan to install new fencing, repair existing fencing, or even keep your new wrought iron fencing well-maintained for years to come. Here are some of the ins and outs of your fencing to help you become familiar with all the most important parts of a wrought iron fence.

- In conclusion, the wheels in sliding doors are more than just a simple accessory; they are the unsung heroes that make the seemingly effortless movement possible. Their importance lies not just in their function but also in their ability to enhance the user experience. As technology continues to advance, we can expect even more sophisticated wheel systems that will further refine the operation of sliding doors, ensuring a perfect blend of aesthetics, functionality, and convenience.

With more than four decades of experience in fencing, you can count on us as your guide for choosing between aluminum fence vs wrought iron fence. We’re going to peel back the layers of this debate from cost considerations to strength, durability, appearance, maintenance, and more.

There are two types of sliding aluminium windows: vertical and horizontal sliding.

In addition to their practical and aesthetic qualities, wrought iron railing panels also contribute to the sustainability narrative

. The material is recyclable, and well-maintained panels can last for generations, reducing the need for frequent replacements and minimizing waste.- Wrought iron pieces have long been appreciated for their beauty and durability. From intricate gates and fences to delicate candle holders and furniture, wrought iron pieces can be found in a wide variety of decorative and functional applications.

- Moreover, hiking allows you to discover new places and appreciate the beauty of the natural world. From majestic mountains and serene forests to breathtaking waterfalls and lush meadows, there's no shortage of awe-inspiring landscapes to explore. Hiking gives you the opportunity to witness Mother Nature in all her glory and marvel at the wonders of the world around you.

In today's eco-conscious environment, choosing materials wisely is more important than ever. Steel is a highly recyclable material, and opting for steel door pull handles can contribute to a sustainable building practice. Manufacturers often take advantage of recycled steel, which minimizes the need for raw materials and lowers the industry's carbon footprint.

- The Versatile World of Aluminum Sliding Wheels

- Rollers are essentially the wheels that allow the smooth opening and closing of the security screen door. Made from high-quality materials such as stainless steel or aluminum, they are built to withstand harsh weather conditions and resist corrosion. Their durability is essential, as a faulty roller can compromise the door's ability to lock securely, leaving your home vulnerable.

In conclusion, ornamental steel stands as a testament to the harmony of aesthetic beauty and practical application. Its diverse range of uses, combined with sustainable qualities and the fusion of technology and craftsmanship, make it a valuable asset in modern design. Whether enhancing an elegant staircase, framing a lush garden, or accentuating a bustling urban space, ornamental steel captures the imagination and inspires creativity, making it an essential element of contemporary architecture and art.

- Wrought iron fence spears, an architectural element that has stood the test of time, are a testament to the enduring appeal of traditional craftsmanship and design. These ornamental features, often seen adorning the tops of fence posts, have been a staple in security and aesthetics for centuries, adding a touch of sophistication and strength to any property.