8 inch dredge pump manufacturers

Latest articles

If youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read MoreChoosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read MoreEspecially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read MoreMud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read More- Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read MoreBecause of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read MoreDredge Pump

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read MoreMixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read MoreIf you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read MoreSlurry Pump

8 inch dredge pump manufacturers...

8 inch dredge pump manufacturers 【8 inch dredge pump manufacturers】

Read More

Popular articles

- Natural rubber is an excellent wear material when handling wet sand slurries. Its strength, resilience and cut resistance have a positive impact on the wear performance of slurry pumps.

- What is Heavy Duty Slurry Pump?

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

- Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

- The size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

- There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

Latest articles

-

If you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

-

If you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

-

The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

-

Determine the size of the pump

-

Slurry Pump

-

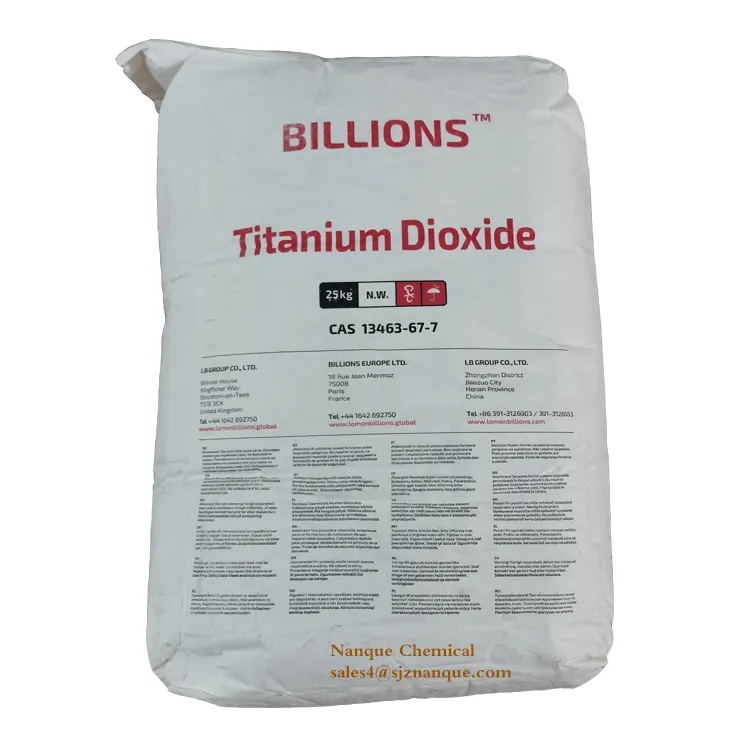

WA Heavy-duty Slurry Pump

Australian researchers examined how titanium dioxide as a food additive affected gut microbiota in mice by orally administering it in drinking water. The study, published in the journal Frontiers in Nutrition in 2019, found the treatment could “alter the release of bacterial metabolites in vivo and affect the spatial distribution of commensal bacteria in vitro by promoting biofilm formation. We also found reduced expression of the colonic mucin 2 gene, a key component of the intestinal mucus layer, and increased expression of the beta defensin gene, indicating that titanium dioxide significantly impacts gut homeostasis.” The changes were then linked to colonic inflammation, along with a higher expression of inflammatory cytokines, which are signal proteins that help with regulation. The researchers concluded that titanium dioxide “impairs gut homeostasis which may in turn prime the host for disease development.”

Algaecidal effect of Lithopon: After 5 years of exposure to weathering in Alpen (Lower Rhine)

pigment lithopone manufacturer.

In food, titanium dioxide is often used as an artificial color additive. Tasha Stoiber, senior scientist at the consumer health nonprofit Environmental Working Group, says titanium dioxide can generally be thought of as a paint primer – it often goes on a hard-shelled candy like Skittles before the color is added to give it a uniform shine.

When it comes to painting, there are many factors to consider. From choosing the right color to ensuring the durability and longevity of your paint, every decision counts. A key ingredient that plays a vital role in achieving the desired finish is titanium dioxide. This extraordinary white pigment revolutionized the paint industry, giving walls around the world unparalleled luster and durability.