high quality close impeller type slurry pump manufacturers

Latest articles

>Slurry Pump

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read More- Keeping clean catch basins clean from solids

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read MoreSlurry pump vs mud pump

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read MoreSelecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read MoreSlurry pump construction materials

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read MoreSlurry Pump Impeller

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read MoreDredge Pump

high quality close impeller type slurry pump manufacturers...

high quality close impeller type slurry pump manufacturers 【high quality close impeller type slurry pump manufacturers】

Read More

Popular articles

- Reduced inventory

- If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

- Corrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

- It is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

- The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

Latest articles

-

Improved flow control

-

Horizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

-

If you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

-

Rubber Lined Slurry Pump

-

Slurry Pump

-

Types of slurry pumps

Links

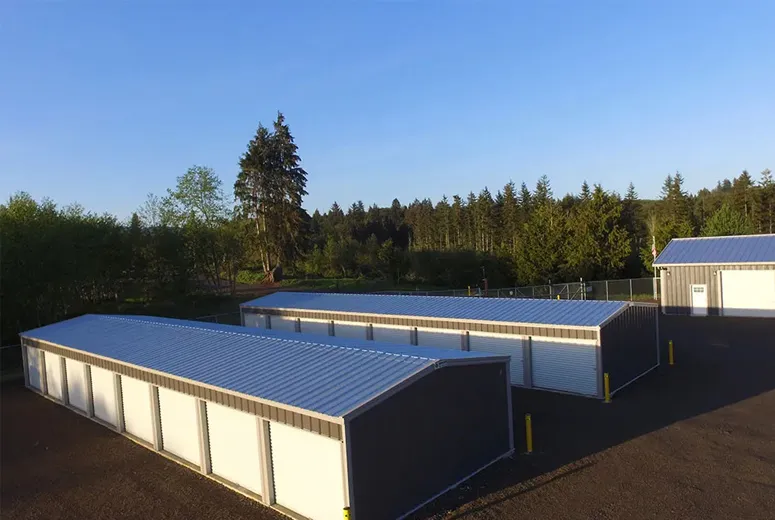

On average, prefab metal buildings can cost anywhere from $10 to $50 per square foot, depending on the factors mentioned above. For instance, a simple carport might cost between $2,000 to $5,000, while a larger commercial building could range from $20,000 to $100,000 or more. It’s essential for buyers to get quotes from multiple manufacturers and contractors to find the best deal.

Red and white pole barns are more than just buildings; they represent a connection to community and heritage. For many, these barns are a symbol of hard work and dedication, embodying the spirit of farming and rural life. They serve as gathering places, where families come together to celebrate milestones or where neighbors collaborate on agricultural projects.