high quality centrifugal sewage pump factory

Latest articles

A typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read MoreWhen slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read MoreChoosing The Right Slurry Pump For Your Application

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read MoreSlurry Pump

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read MoreSlurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read MoreSlurry Pump

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read MoreWhat is the optimum seal arrangement for the application?

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read MoreA , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read MoreChoosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

high quality centrifugal sewage pump factory...

high quality centrifugal sewage pump factory 【high quality centrifugal sewage pump factory】

Read More

Popular articles

- If you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

- Consider the pump components

- Consideration should be given to installing mixers on guide rods in the catch basin/tank to keep solids in suspension and avoid settling in the catch basin/tank. When investing in a slurry pump, you want to pump slurry that includes solids, not just dirty water. Therefore, it is important to make sure that the pump is doing this; by using an agitator, the pump is fed with solids and pumping the slurry.

- How much solids damage can the customer tolerate?

- Slurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

- Another way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

Latest articles

-

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

-

Determine the operating parameters of the pump.

-

- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

-

- transport solids hydraulically

-

>Slurry Pump

-

In addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

Links

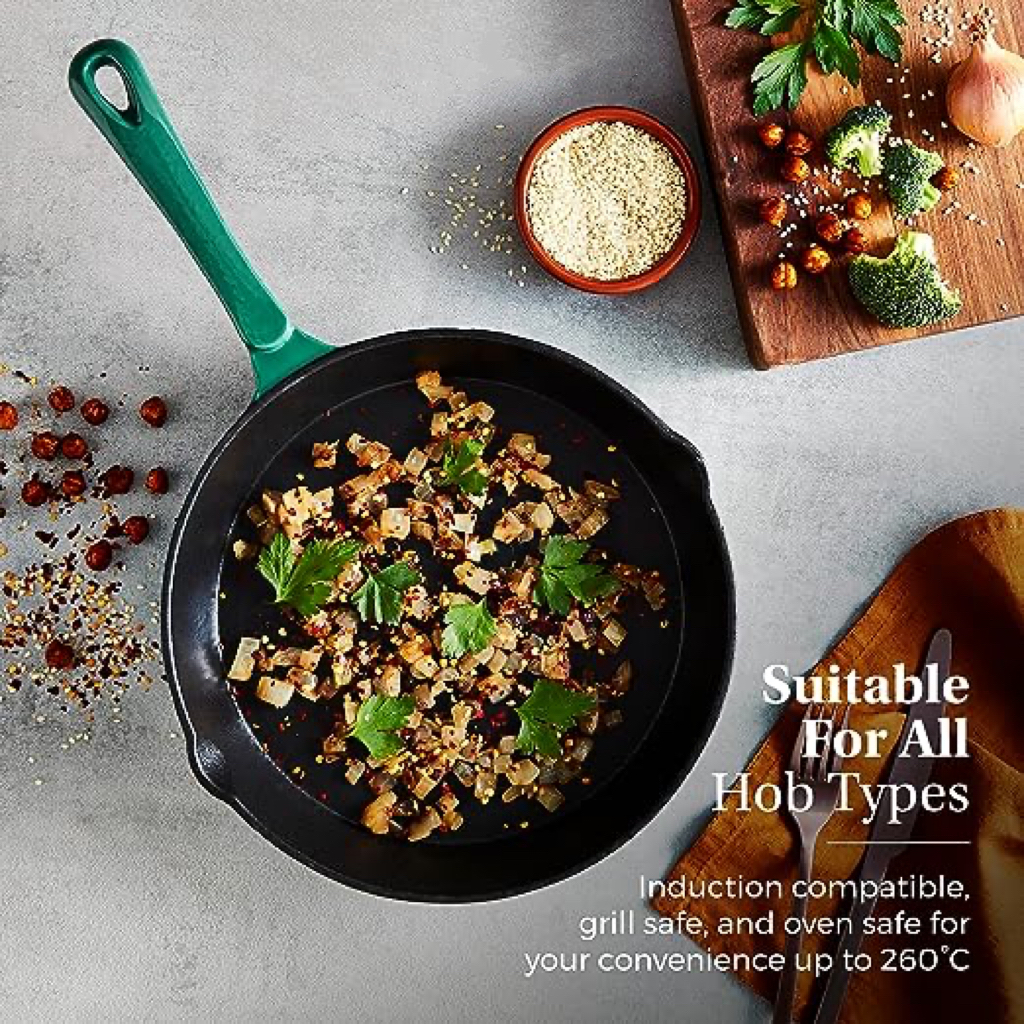

- Enamel cooking ware has been gaining popularity in recent years due to its many benefits. This type of cookware is made by coating metal, usually cast iron or steel, with a layer of enamel. This enamel layer not only adds a pop of color to your kitchen, but also provides a non-stick surface that is easy to clean and scratch-resistant.

When it comes to size, both the frypan and skillet are available in various sizes. What sets them apart is the range of sizes offered. The size of frypans usually range from 15cm to 30cm, with the most popular sizes being between 24cm and 26cm.

Skillet vs. Saute Pan: What's the Difference?

The process of coating the pan with oil and heating it to create a non-stick surface not only improves its performance but also adds a layer of natural non-stick properties The process of coating the pan with oil and heating it to create a non-stick surface not only improves its performance but also adds a layer of natural non-stick properties

The process of coating the pan with oil and heating it to create a non-stick surface not only improves its performance but also adds a layer of natural non-stick properties The process of coating the pan with oil and heating it to create a non-stick surface not only improves its performance but also adds a layer of natural non-stick properties grill pan iron. Over time, with proper care, the seasoning builds up, turning the pan into a unique, personalized cooking tool.

grill pan iron. Over time, with proper care, the seasoning builds up, turning the pan into a unique, personalized cooking tool.

cast iron frying skillet. When properly seasoned, the pan develops a non-stick surface that allows food to slide off easily. To season a cast iron skillet, simply apply a thin layer of oil to the surface and bake it in the oven at a low temperature until the oil is absorbed and a dark, shiny finish forms.

cast iron frying skillet. When properly seasoned, the pan develops a non-stick surface that allows food to slide off easily. To season a cast iron skillet, simply apply a thin layer of oil to the surface and bake it in the oven at a low temperature until the oil is absorbed and a dark, shiny finish forms.This article will provide an in-depth comparison of fry pans and French skillets, including their designs and uses, so you can understand the differences between them.

You can use skillets for pan-frying or searing a few servings of meat. However, dishes that cook quickly and need constant stirring or flipping, such as a beef stir fry or a spinach mushroom omelet, gives a skillet a chance to really shine.

Cast iron bacon presses and steak weights are versatile kitchen tools that offer a range of benefits for cooking enthusiasts and professional chefs. This article explores the features, applications, and advantages of these culinary tools, highlighting their ability to elevate the cooking process and enhance the flavors of various dishes.

flat top cast iron griddle.

If you're looking to buy cast iron cookware, it's worth researching different brands and reading reviews to make sure you're getting the best value for your money. Some well-known brands offer a variety of cast iron cookware at competitive prices, making it easier to find an option that fits your budget. Additionally, shopping at reputable retailers or online marketplaces can provide a variety of options and potential discounts.

Tossing Ability

Large enameled pots with lids are perfect for cooking large batches of soups, stews or pasta. Large Enamel Pots With Lids spacious interior provides plenty of room for cooking and simmering ingredients, making it ideal for feeding a crowd or preparing meals ahead of time. The enameled cast iron lid helps lock in heat and moisture, ensuring your dishes cook to perfection.

If frying pans and skillets are the same things, then what's with all the confusion between the terminology?

This makes skillets the generally larger option between the two, as its overall diameter can usually range between 20cm to 40cm. The generally larger size of the skillet makes it a better choice to feed families or a crowd. Popular skillet sizes are often the 25cm and 30cm ones, especially so for those who enjoy the versatility to cook single meal portions and larger ones.

Stainless Steel Frying Pans

In conclusion, when looking for cookware set for your kitchen, consider the benefits of cast iron cookware sets. Whether you choose an 8-piece cast iron cookware set, 10-piece cast iron cookware set, 13-piece cookware set, or 20-piece cast iron cookware set, you'll be investing in durable, versatile cookware that will enhance your cooking experience.