china chemical slurry pump factory

Latest articles

Slurry Pump

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read MoreDry Installation

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read MoreSlurry Pump

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read MoreMagnetite mixing

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read MoreIf you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read Moretarget=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read MoreIncludes a large number of solids or particles.

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read MoreLess downtime

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read More- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read More>Slurry Pump

china chemical slurry pump factory...

china chemical slurry pump factory 【china chemical slurry pump factory】

Read More

Popular articles

- What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

- - Low noise level - Operating underwater results in low noise or even silent operation.

- As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

- A clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

- Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

- Consider the impeller. Slurry pumps must have thicker vanes than water pumps to prevent wear. Due to the increased thickness, there will be fewer vanes, otherwise the passages will be too narrow and will affect the performance of the pump. The impeller should have a large enough passage so that the largest solid particles can pass through without clogging.

Latest articles

-

If the exact in-pump viscosity of the product is unknown, CSI can help

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

-

Determine the size of the pump

-

If you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

-

WL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

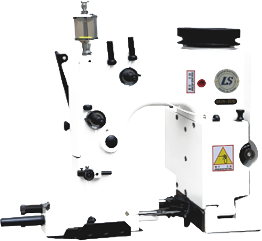

The Mechanism Behind the Union Lockstitch Sewing Machine

Compact Design:

5. Simplicity and Ease of Use Modern double needle sewing machines are designed with user-friendliness in mind. Many models come with guided threading systems, automatic tension settings, and intuitive controls, making them suitable for both beginners and experienced sewers alike.

What is a Presser Foot?

1. Machine Type There are various types of overlocking machines, including manual and automated options. Automated machines tend to offer increased efficiency and consistency, making them ideal for larger operations.

Furthermore, many heavy-duty machines come with comprehensive warranties and customer support, providing additional peace of mind. A well-known brand with a solid reputation will likely offer better service and parts availability, ensuring that your machine works effectively for years to come.

what are heavy duty sewing machines used for

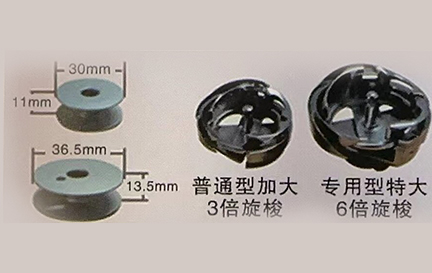

shuttle hook case. If necessary, replace the shuttle hook case or seek professional help.

what is a heavy duty sewing machine. The solid construction of heavy-duty machines ensures that they won't wobble or shift while sewing, allowing for precise and accurate stitching every time.

When it comes to sewing in various fabrics, especially thicker materials like leather, canvas, or multiple layers of fabric, having the right kind of sewing machine is essential. The walking foot sewing machine has gained popularity among hobbyists and professionals alike due to its unique feeding mechanism that ensures a smooth sewing experience with superior results. If you are on the lookout for a walking foot sewing machine for sale, it's essential to understand its features, benefits, and what to consider before making a purchase.

Heavy Duty Home Sewing Machines The Ultimate Tool for Every Sewing Enthusiast

Advantages of Using Coverstitch

3. Specialized Needles Using the right needles is crucial when sewing leather and fur. Leather needles have a wedge-shaped point designed to pierce through the material without causing damage. For fur, a slightly rounded needle is more appropriate to slide between the fur fibers without pulling them out. Many sewing machines designed for these materials often come with a selection of specialized needles.

When working with thick materials, it’s essential to have control over the presser foot pressure. An adjustable presser foot allows you to customize the amount of pressure applied to the fabric, which is vital for achieving even stitches and preventing puckering or dragging. Make sure the sewing machine you choose has this feature.

Conclusion

Time Efficiency

3. Technology and Features The integration of advanced technology into sewing machines can significantly affect prices. Machines equipped with computerized controls, user-friendly interfaces, and automation capabilities typically have a higher price tag. However, they also offer greater efficiency, precision, and reduced labor costs, which can be beneficial in the long run.

1. Efficiency Industrial overlockers are built for high-speed stitching, allowing businesses to produce garments quickly. They can sew, trim, and overcast fabric edges in a single pass, significantly reducing production time.

3. SINGER Heavy Duty 4423 This budget-friendly option doesn’t compromise on quality. With a strong motor, a variety of stitch options, and a stainless steel bedplate, the SINGER Heavy Duty 4423 is perfect for beginners who want to sew leather and vinyl without breaking the bank.

Industrial Sewing Machines: These machines are mostly made of high-quality metals and are made to last. They can withstand wear and tear and are made to last for many years under intensive usage.

Some thinner materials will require a special kind of stitch and also a lower ironing temperature. Thicker materials might also need to be sewn in layers. This process requires a powerful heavy duty sewing machine that can easily reach through the material without breaking or bending the needle.

For those in the market, there are various models of manual leather sewing machines available for sale. When searching, consider factors such as the type of leather you’ll be working with, the machine’s stitch options, and the level of portability that suits your lifestyle. Additionally, checking for user reviews and seeking recommendations from seasoned leatherworkers can help guide your purchase.

The hi-speed lockstitch machine operates using a simple yet effective mechanism. It employs a lockstitch formation, where a top thread and a bobbin thread interlock to create a strong, durable seam. This type of stitch is renowned for its ability to withstand stress and is exceptionally common in industrial applications. The machine’s hi-speed functionality allows it to sew at rates exceeding 5,000 stitches per minute, making it a crucial asset in high-volume production environments.

As technology continues to advance, the double stitch machine is evolving alongside it. Modern machines are now equipped with computerized controls that allow for precise stitch length adjustments, automatic thread tension regulation, and even intricate embroidery capabilities. This technological integration not only enhances the quality of the final product but also provides manufacturers with greater control over the production process.

In the realm of industrial manufacturing, efficiency and precision are paramount. Among the myriad of machines that contribute to the production process, the PP (Polypropylene) bag stitching machine plays a vital role in the packaging industry. As the demand for durable and versatile packaging solutions continues to rise, understanding the functionality, evolution, and significance of PP bag stitching machines is crucial.

As sustainability becomes increasingly important in modern business practices, the handheld bag closer also offers an eco-friendly approach to packaging. With the capability to seal recyclable and biodegradable materials effectively, businesses can adopt greener packaging solutions. By minimizing the use of non-recyclable materials and ensuring a secure closure that prevents product waste, these devices help companies align with environmental objectives.

What is a Twin Needle?

Enhancing Hemming

To get the best results when using a walking foot, there are a few tips to keep in mind. First, always test your stitch on a scrap piece of fabric before starting on your actual project. This will help you adjust tension and stitch length as necessary.

Working with fur and leather opens a vast array of creative possibilities, from making coats and jackets to crafting bags and accessories. A dedicated sewing machine designed for these materials enables both amateur and professional designers to experiment with textures, styles, and finishes. The satisfaction that comes from creating a beautifully sewn piece from such luxurious materials is unparalleled.

Exploring Self-Threading Sewing Machines for Sale