slurry warman pump drawings factories

Latest articles

WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read MoreSubmersible Slurry Pump

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read MoreIn addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read More1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read Morehow-does-a-dredge-pump-work

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read MoreLarger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read MoreIt is important that the pump you choose has components that will not wear out from abrasive slurries.

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read MoreSlurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read More>Slurry Pump VS Mud Pump

slurry warman pump drawings factories...

slurry warman pump drawings factories 【slurry warman pump drawings factories】

Read More

Popular articles

- Some models can generate discharge pressures up to 260 ft. (80 m).

- Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

- target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

- Safety

- How does a dredge pump work?

- Many types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

Latest articles

-

Consider the pump components

-

A target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

-

BCT Ceramic Slurry Pumps

-

If you want to know more information about the best heavy duty slurry pump, welcome to >contact us today or request a quote.

-

The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

-

Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

non stick cast iron grill pan. The grill marks created by the pan give food a delicious charred flavor, similar to what you would get from an outdoor grill. This makes it a great option for those who want to enjoy grilled foods but don't have access to an outdoor grill.

Be sure to dry the skillet thoroughly with a clean towel to prevent rusting Be sure to dry the skillet thoroughly with a clean towel to prevent rusting

Be sure to dry the skillet thoroughly with a clean towel to prevent rusting Be sure to dry the skillet thoroughly with a clean towel to prevent rusting cleaning cast iron skillet with salt. You can also place the skillet on a stovetop burner on low heat to evaporate any remaining moisture.

cleaning cast iron skillet with salt. You can also place the skillet on a stovetop burner on low heat to evaporate any remaining moisture.

This thoughtful design also allows for easy cleaning, as the pan can be safely submerged in water without the risk of damaging the handle This thoughtful design also allows for easy cleaning, as the pan can be safely submerged in water without the risk of damaging the handle

This thoughtful design also allows for easy cleaning, as the pan can be safely submerged in water without the risk of damaging the handle This thoughtful design also allows for easy cleaning, as the pan can be safely submerged in water without the risk of damaging the handle cast iron grill pan with detachable handle.

cast iron grill pan with detachable handle.

red square grill pan. By grilling your food instead of frying it, you can reduce the amount of oil and fat in your dishes. This can lead to lower calorie intake and a healthier diet overall.

Advantages:

big bacon press. It's not just for meat; you can also use it to press sandwiches, make panini, and even create decorative shapes for your food. The possibilities are endless, and the Big Bacon Press will quickly become an essential tool in your kitchen.

big bacon press. It's not just for meat; you can also use it to press sandwiches, make panini, and even create decorative shapes for your food. The possibilities are endless, and the Big Bacon Press will quickly become an essential tool in your kitchen.

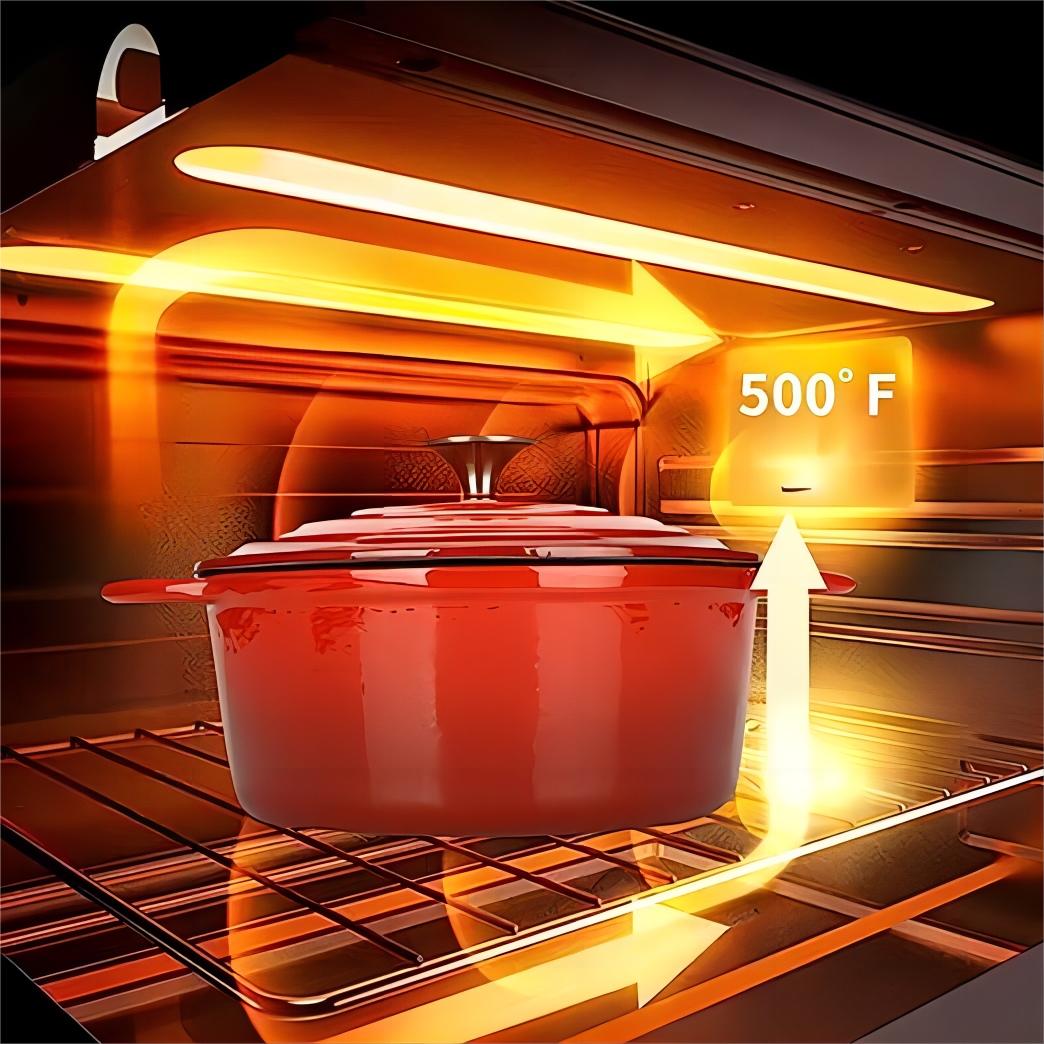

This makes them perfect for recipes that require a crispy top, such as baked casseroles or roasted vegetables This makes them perfect for recipes that require a crispy top, such as baked casseroles or roasted vegetables

This makes them perfect for recipes that require a crispy top, such as baked casseroles or roasted vegetables This makes them perfect for recipes that require a crispy top, such as baked casseroles or roasted vegetables buy cast iron frying pan. Additionally, the heavy-bottomed design enables the pan to endure high heat, making it ideal for searing meats—the intense heat creates a flavorful crust while sealing in the juices.

buy cast iron frying pan. Additionally, the heavy-bottomed design enables the pan to endure high heat, making it ideal for searing meats—the intense heat creates a flavorful crust while sealing in the juices.

On the other hand, if you need a large enameled pot to cater to larger groups or to cook more food, there are many options to choose from. The large enamel pot is perfect for making stews, casseroles, and one-pot meals for the whole family. They're also great for boiling pasta, making stock, or preparing large batches of soup.

Kitchen Cookware Multifunction Rectangular Frying Pan Cast lron Wok

With gentle yet firm pressure, press down on the bacon weight press to flatten the bacon against the cooking surface. This action helps prevent curling and encourages even cooking, resulting in crispy, perfectly cooked bacon.

This is where most of the confusion between frying pans, skillets, and different terminology for pots and pans stems from.

bacon press cast iron.

Cleaning Cast Iron Camp Oven

It can be used for frying, sautéing, searing, baking, or even boiling water It can be used for frying, sautéing, searing, baking, or even boiling water

It can be used for frying, sautéing, searing, baking, or even boiling water It can be used for frying, sautéing, searing, baking, or even boiling water cast iron fry pan camping. Its deep sides and solid handle allow for easy manipulation of ingredients, while its large surface area accommodates generous portions, ideal for feeding a hungry camping crew.

cast iron fry pan camping. Its deep sides and solid handle allow for easy manipulation of ingredients, while its large surface area accommodates generous portions, ideal for feeding a hungry camping crew. Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration

Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration cast iron enamel pan set.

cast iron enamel pan set.