high quality slurry pump for vapour blasting

Latest articles

For certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreThe Difference Between Flushing And Quenching in Slurry Pump Seals

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreSlurry pumps can be used for.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreSlurry Pump

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read More>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreIf the exact in-pump viscosity of the product is unknown, CSI can help

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreSlurry Pump

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreSlurry Pump

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read MoreStep 1

high quality slurry pump for vapour blasting...

high quality slurry pump for vapour blasting 【high quality slurry pump for vapour blasting】

Read More

Popular articles

- The rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

- First, what is a slurry? A slurry is a semi-liquid mixture, usually consisting of fine particles. Examples of slurries can include manure, cement, starch, or coal suspended in water. There are countless other combinations that can be considered slurries. Because of the added particles and thicker consistency, special pump requirements should be considered. A standard pump may be able to handle the fluid, but not as effectively as a properly sized slurry pump.

- Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

- Slurry pump considerations

- Slurry Pump

- Determine the operating parameters of the pump.

Latest articles

-

Step 4

-

A clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

-

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

-

Slurry Pump

-

WA Heavy-duty Slurry Pump

-

What is a dredging pump?

Links

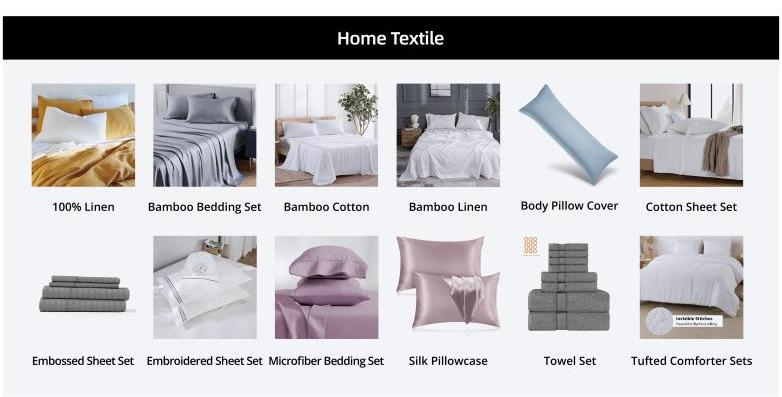

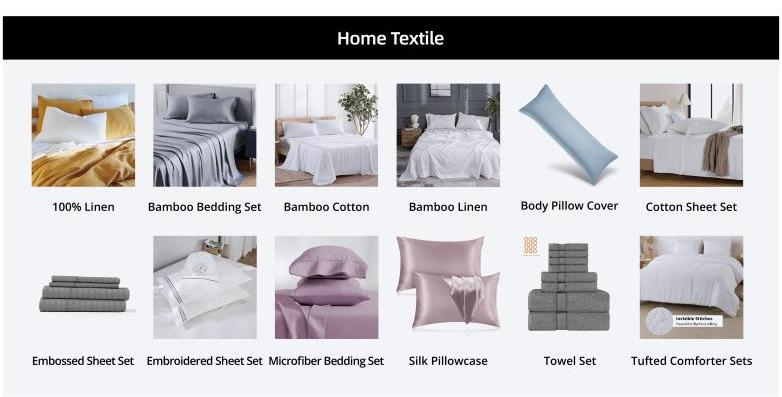

Bed Sheet Buying Guide

Cotton is a soft and fluffy natural fiber that comes from the cotton plant. They are harvested from the boll of the plant, then spun and woven into durable cotton sheets.

Synthetic fillers, like polyester, offer a more affordable alternative with comparable insulation properties Synthetic fillers, like polyester, offer a more affordable alternative with comparable insulation properties

Synthetic fillers, like polyester, offer a more affordable alternative with comparable insulation properties Synthetic fillers, like polyester, offer a more affordable alternative with comparable insulation properties duvet cover and filler. Feather fillers provide a medium level of warmth and are generally more affordable than down.

duvet cover and filler. Feather fillers provide a medium level of warmth and are generally more affordable than down. Their quick-drying properties also mean that they won't take up too much space in your laundry basket Their quick-drying properties also mean that they won't take up too much space in your laundry basket

Their quick-drying properties also mean that they won't take up too much space in your laundry basket Their quick-drying properties also mean that they won't take up too much space in your laundry basket lightweight towels.

lightweight towels.

bath towel size in hotel industry. They provide ample coverage for guests of all shapes and sizes, ensuring that everyone can comfortably wrap themselves in the towel without feeling exposed or uncomfortable. This inclusivity is important in creating a positive guest experience and ensuring that all guests feel welcomed and cared for during their stay.

Bed sheets serve a variety of purposes:

1000 tc duvet cover. The cover is also machine washable, allowing for easy cleaning and maintenance. With proper care, this duvet cover will maintain its softness and beauty for years to come.

Microfiber Sheets Care

Fitted sheets with deep pockets can accommodate thicker mattresses commonly found in motorhomes Fitted sheets with deep pockets can accommodate thicker mattresses commonly found in motorhomes

Fitted sheets with deep pockets can accommodate thicker mattresses commonly found in motorhomes Fitted sheets with deep pockets can accommodate thicker mattresses commonly found in motorhomes motorhome sheets that fit. Elastic all around the sheet ensures it stays in place during transit. Flat sheets with generous dimensions allow for easy tucking and less likelihood of coming loose.

motorhome sheets that fit. Elastic all around the sheet ensures it stays in place during transit. Flat sheets with generous dimensions allow for easy tucking and less likelihood of coming loose.With its smooth finish, incredible durability, and resistance to pilling, Egyptian cotton is the highest quality cotton you can find. It’s typically made with an extra-long staple — the longest cotton fiber available — and can be fairly pricey for the real stuff.

A duvet is similar to a comforter except it requires the use of a duvet cover, where a comforter does not. Typically, a duvet is solid white and stuffed with down or a down alternative.

A higher fill power ensures the insert retains its loft, maintaining its shape and providing consistent warmth over time A higher fill power ensures the insert retains its loft, maintaining its shape and providing consistent warmth over time

A higher fill power ensures the insert retains its loft, maintaining its shape and providing consistent warmth over time A higher fill power ensures the insert retains its loft, maintaining its shape and providing consistent warmth over time plain duvet insert. For a lightweight option, a fill power between 400-500 is suitable, while a heavier warmth would require a fill power of 600 or above.

plain duvet insert. For a lightweight option, a fill power between 400-500 is suitable, while a heavier warmth would require a fill power of 600 or above. turkish towel set. First, consider the size of the towels. Turkish towels are typically larger than standard bath towels, so make sure you choose a set that is appropriate for your needs. Second, think about the color and pattern. As mentioned earlier, Turkish towels come in a wide range of colors and patterns, so take some time to browse through different options to find one that you love. Finally, consider the material. As with any type of towel, it's important to choose one that is made from high-quality materials that will stand up to regular use.

turkish towel set. First, consider the size of the towels. Turkish towels are typically larger than standard bath towels, so make sure you choose a set that is appropriate for your needs. Second, think about the color and pattern. As mentioned earlier, Turkish towels come in a wide range of colors and patterns, so take some time to browse through different options to find one that you love. Finally, consider the material. As with any type of towel, it's important to choose one that is made from high-quality materials that will stand up to regular use. Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests

Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests wholesale hotel linens.

wholesale hotel linens.Antibacterial Towels

Fitted sheets have the potential to wear out more quickly than other bedding elements for a few reasons: 1. The elastic sewn on the edges create more stress on the fabric, especially when the fabric is being stretched across the mattress repeatedly. 2. The weight of our bodies shifting while sleeping creating friction on the fabric, causing wear.