ah slurry pump factory

Latest articles

Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read MoreSlurry Pump

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read MoreDredge Pump

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read MoreTypically, slurries are.

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read MoreSelecting a dredge pump

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read MoreThe same point of slurry pump and mud pump

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read MoreChoosing Dry Slurry Pumps Versus Submersible Slurry Pumps

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read MoreThere is a better way to pump sewage, overflows and other collected dirty water around the plant.

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

ah slurry pump factory...

ah slurry pump factory 【ah slurry pump factory】

Read More

Popular articles

- Slurry Pump Considerations

- AIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

- The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

- Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

- - Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

- Safety

Latest articles

-

Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

-

There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

-

Slurry Pump

-

target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

-

Working principle

-

There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

Links

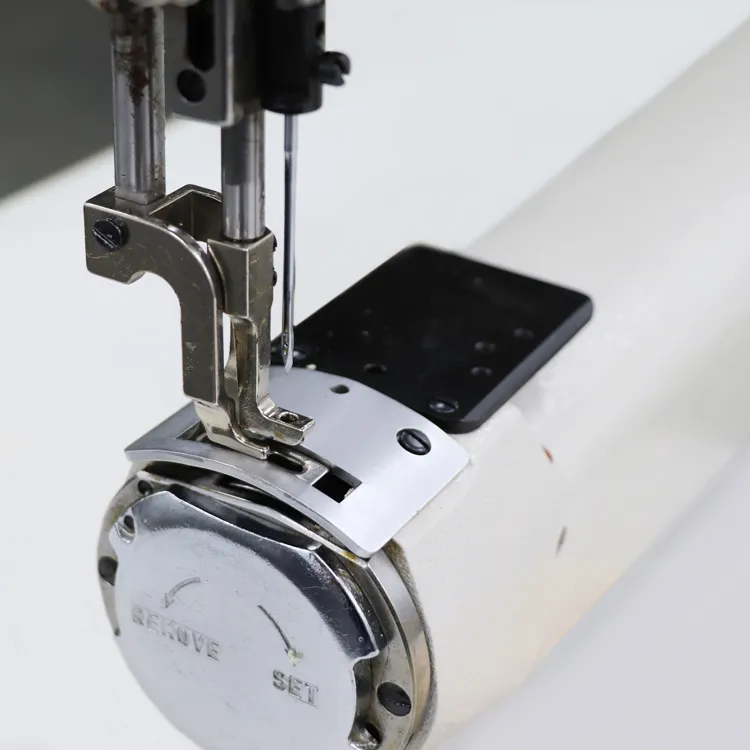

The lockstitch sewing machine is an essential piece of equipment in the textile industry, renowned for its efficiency and versatility. Its operation is fundamental to modern garment manufacturing, providing a durable and reliable stitch that is crucial for constructing clothing and other fabric-based products.