china multistage slurry pump factory

Latest articles

If you have experience pumping slurries, you know it's not an easy task. Slurries are heavy and difficult to pump. They cause excessive wear on pumps and their components and are known to clog suction and discharge lines if not moving fast enough. Most importantly, it’s a challenge to make slurry pumps last for a reasonable amount of time. But, there are a few things you can do to extend the life of your slurry pump and make pumping slurry less of a challenge.

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read MoreThe selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read MoreWY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read MoreSafety

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read MoreRepairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read MoreIf a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read MoreDepending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read MoreChromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read MoreDetermine the nature of the material to be pumped

china multistage slurry pump factory...

china multistage slurry pump factory 【china multistage slurry pump factory】

Read More

Popular articles

- Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

- What are the materials used to construct the pump?

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- Make sure you follow the basic rules of pump piping.

- - Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

- Selecting a dredge pump

Latest articles

-

How does a dredge pump work?

-

Find a professional slurry pump supplier

-

Flushing is defined as a fluid which is introduced into the seal cavity on the process fluid side, close to the seal face, and is normally used to cool and lubricate the seal face.

-

Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

-

Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

-

>Slurry Pump

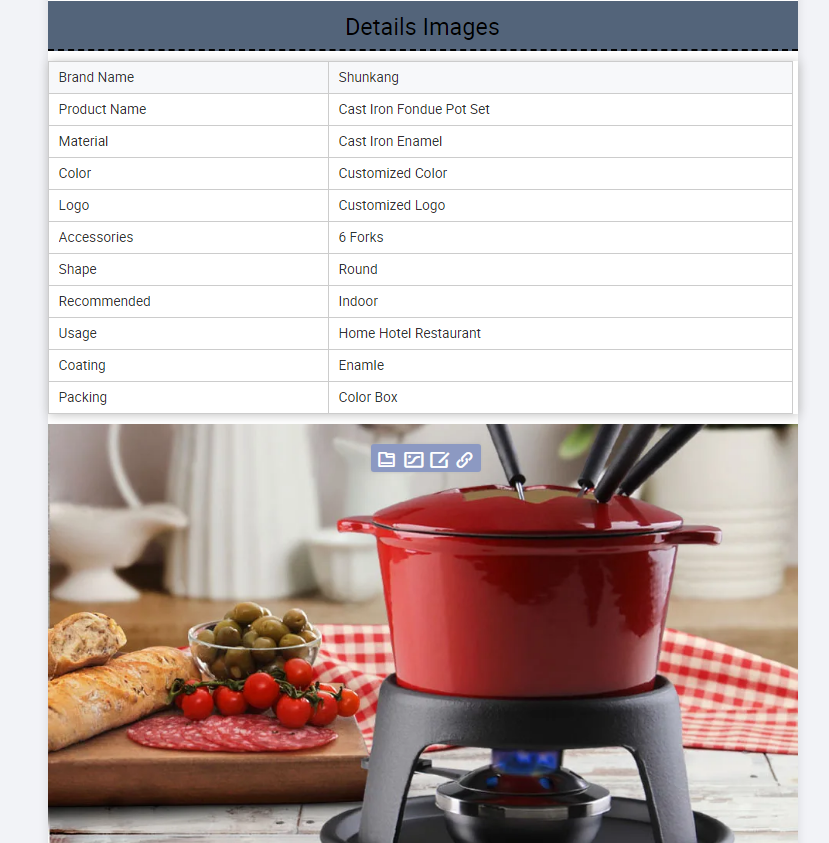

Home Cooking: Black cast iron griddles and grill pans are popular in home kitchens, offering a convenient and effective way to achieve professional-quality searing, grilling, and cooking results. They are suitable for a variety of cooking techniques and are easy to maintain.

Nowadays, “French skillet” refers to the specific design aspects of the cookware rather than its place of origin.

One of the most popular types of Dutch ovens for outdoor cooking is the round cast iron Dutch oven. This classic design features a deep round pot and tight-fitting lid, perfect for cooking stews, soups, and roasts over an open fire. The Round Cast Iron Dutch Oven shape distributes heat evenly, ensuring food is cooked to perfection every time.

This is particularly useful for dishes that require precise temperature control, such as sauces, stews, and roasts This is particularly useful for dishes that require precise temperature control, such as sauces, stews, and roasts

This is particularly useful for dishes that require precise temperature control, such as sauces, stews, and roasts This is particularly useful for dishes that require precise temperature control, such as sauces, stews, and roasts non stick enamel cookware. The even heat distribution also helps to prevent hot spots, which can cause food to burn or stick to the bottom of the pan.

non stick enamel cookware. The even heat distribution also helps to prevent hot spots, which can cause food to burn or stick to the bottom of the pan.Cast Griddle Plates Size

Enameled Cast Iron: Enameled cast iron Dutch ovens combine the benefits of cast iron with the convenience of an enamel coating. They are resistant to acidic foods, easy to clean, and come in a range of vibrant colors.

Copper Frying Pans

Moreover, the even heat distribution prevents hotspots, ensuring dishes cook uniformly Moreover, the even heat distribution prevents hotspots, ensuring dishes cook uniformly

Moreover, the even heat distribution prevents hotspots, ensuring dishes cook uniformly Moreover, the even heat distribution prevents hotspots, ensuring dishes cook uniformly large enamel cast iron pot.

large enamel cast iron pot.Aside from their looks, one of the distinct characteristics of copper pans is the fact that they cool rapidly once removed from the heat. Copper is strong and notoriously conductive, so it makes for long-lasting, high-performance, and incredibly responsive cookware—perfect for jam, caramel, and other delicate sauces, as well as searing and sautéing, as well.

Made from: iron, which heats slowly but evenly and stays scorching hot

FAQS

Skillet & Saute Pan: The Main Distinctive Features and Applications