china warman slurry pump gland seal manufacturer

Latest articles

The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read MoreSubmersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read MoreThere is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read Morehow-does-a-dredge-pump-work

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read MorePositive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read More3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read MoreMetal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read MoreUnderwater installation

china warman slurry pump gland seal manufacturer...

china warman slurry pump gland seal manufacturer 【china warman slurry pump gland seal manufacturer】

Read More

Popular articles

- Pump selection for FGD

- Selecting And Operating A Slurry Pump

- A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

- These conditions include

- Some models can generate discharge pressures up to 260 ft. (80 m).

- What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. , Slurry pumps, are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

Latest articles

-

There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

-

Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

-

The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

-

Firstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

-

Slurry Pump

-

Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

Links

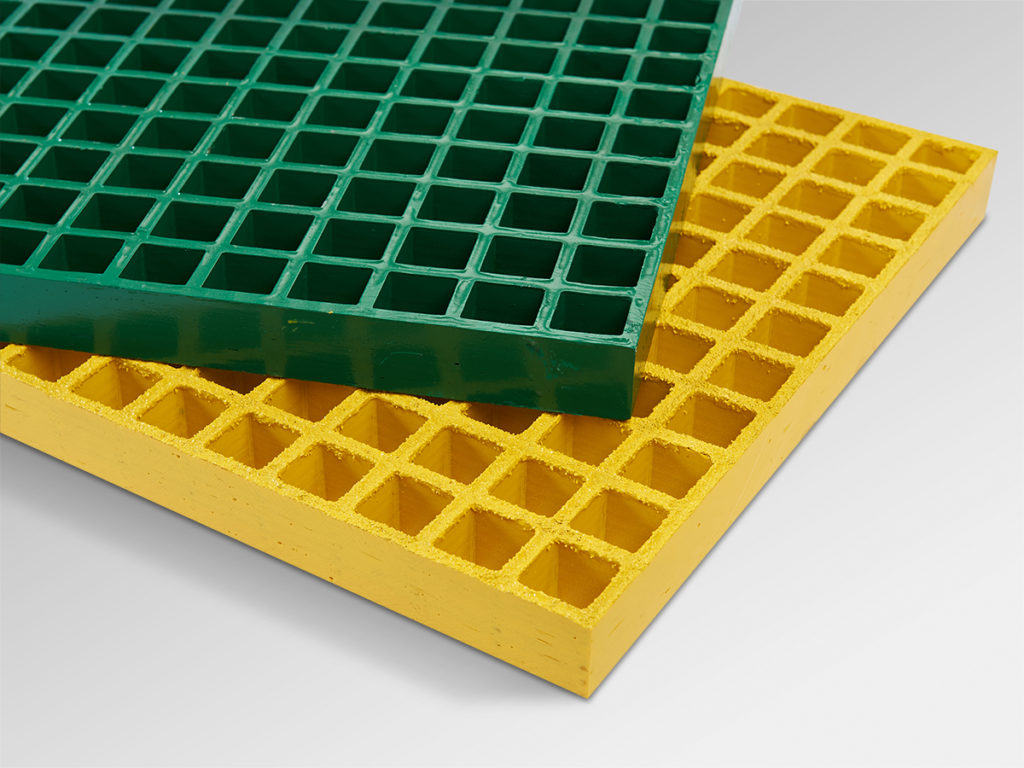

Available in both square and grid patterns, fiberglass grating is widely used due to its low maintenance cost combined with unmatched resilience. Unlike metal gratings, which in certain environments can require extended product life cycle; fiberglass grating is corrosion and rust free, making it more cost effective. Chemical attacks are also not an issue with fiberglass gratings, ensuring its durability. Ideal for the corrosive environment, FRP gives it the complete value for the money.

- Vessels and tanks are essential components in various industries, including chemical, pharmaceutical, food and beverage, and water treatment. These containers are used for storing and transporting liquids, gases, and bulk materials. They come in various shapes and sizes, depending on the specific requirements of the application.

What Are The Performance Advantages Of Fiberglass Grating

4.Flat fiberglass cover plate

Flat fiberglass cover plate reinforced by fiber mesh cloth,fiber chopped mat and resin by hand lay up. Plate cover appearance is smooth, nonslip paving sand surface and slip markings surface.Under normal circumstances, flat fiberglass panels are used in combination with the fiberglass reinforced grating.

Strong, Lightweight and Corrosion-Resistant

Molded FRP Grating has the strength of steel, but it won’t corrode like steel can.

Gratings & Covers

fiberglass stair tread. Unlike materials such as carpet or hardwood, which require regular cleaning and upkeep, fiberglass requires only occasional wiping with a damp cloth to keep it looking pristine. This low-maintenance aspect is particularly appealing to busy households or those looking for a hassle-free addition to their living space.

fiberglass stair tread. Unlike materials such as carpet or hardwood, which require regular cleaning and upkeep, fiberglass requires only occasional wiping with a damp cloth to keep it looking pristine. This low-maintenance aspect is particularly appealing to busy households or those looking for a hassle-free addition to their living space.

This reduces walking or drifting of the drill, ensuring more accurate hole placement This reduces walking or drifting of the drill, ensuring more accurate hole placement

This reduces walking or drifting of the drill, ensuring more accurate hole placement This reduces walking or drifting of the drill, ensuring more accurate hole placement spiral drill rod. Additionally, the spiral design helps to distribute heat generated during drilling, reducing the risk of thermal damage to the workpiece or the drill rod itself.

spiral drill rod. Additionally, the spiral design helps to distribute heat generated during drilling, reducing the risk of thermal damage to the workpiece or the drill rod itself.

small pneumatic jack hammer. Most models feature a set of ergonomic handles that make it comfortable to hold and control. This allows the operator to maintain a firm grip on the tool while still delivering powerful blows to the work surface.

Furthermore, their non-conductive properties make them safe to use in environments with electrical hazards, adding an extra layer of safety to industrial operations Furthermore, their non-conductive properties make them safe to use in environments with electrical hazards, adding an extra layer of safety to industrial operations

Furthermore, their non-conductive properties make them safe to use in environments with electrical hazards, adding an extra layer of safety to industrial operations Furthermore, their non-conductive properties make them safe to use in environments with electrical hazards, adding an extra layer of safety to industrial operations fiberglass chemical tanks.

fiberglass chemical tanks. However, don't compromise on quality just to save a few dollars However, don't compromise on quality just to save a few dollars

However, don't compromise on quality just to save a few dollars However, don't compromise on quality just to save a few dollars cheap jack hammer for sale. Look for a model that offers good value for money and meets your requirements.

cheap jack hammer for sale. Look for a model that offers good value for money and meets your requirements.