trash slurry pump manufacturer

Latest articles

Ideal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read MoreSlurry Pump

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read MoreFor pumping abrasive slurries, these types of pumps can also be made from specialised high-wear alloys. Hardened stainless steel is also a common choice for abrasive slurries.

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read MoreDredge Pump Features

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read MoreWhen pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read MoreSlurry Pump

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read MoreWhat is 'slurry'?

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read MoreMixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read MoreWhat style of pump is suitable?

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read MoreIs the discharge configuration suitable for abrasive slurries?

trash slurry pump manufacturer...

trash slurry pump manufacturer 【trash slurry pump manufacturer】

Read More

Popular articles

- Slurry Pump

- -When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

- In harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

- Lifetime use

- - Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

- The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

Latest articles

-

The size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

-

Find a professional slurry pump supplier

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

Rubber Lined Slurry Pump

-

Horizontal pumps are the most commonly used type of slurry pump and therefore have the advantage of being easy to install or maintain, a wide range of flow parameters to choose from and a wide range of design materials to choose from. One of the advantages of vertical pumps, however, is the relatively small amount of floor space required for installation.

-

Pumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

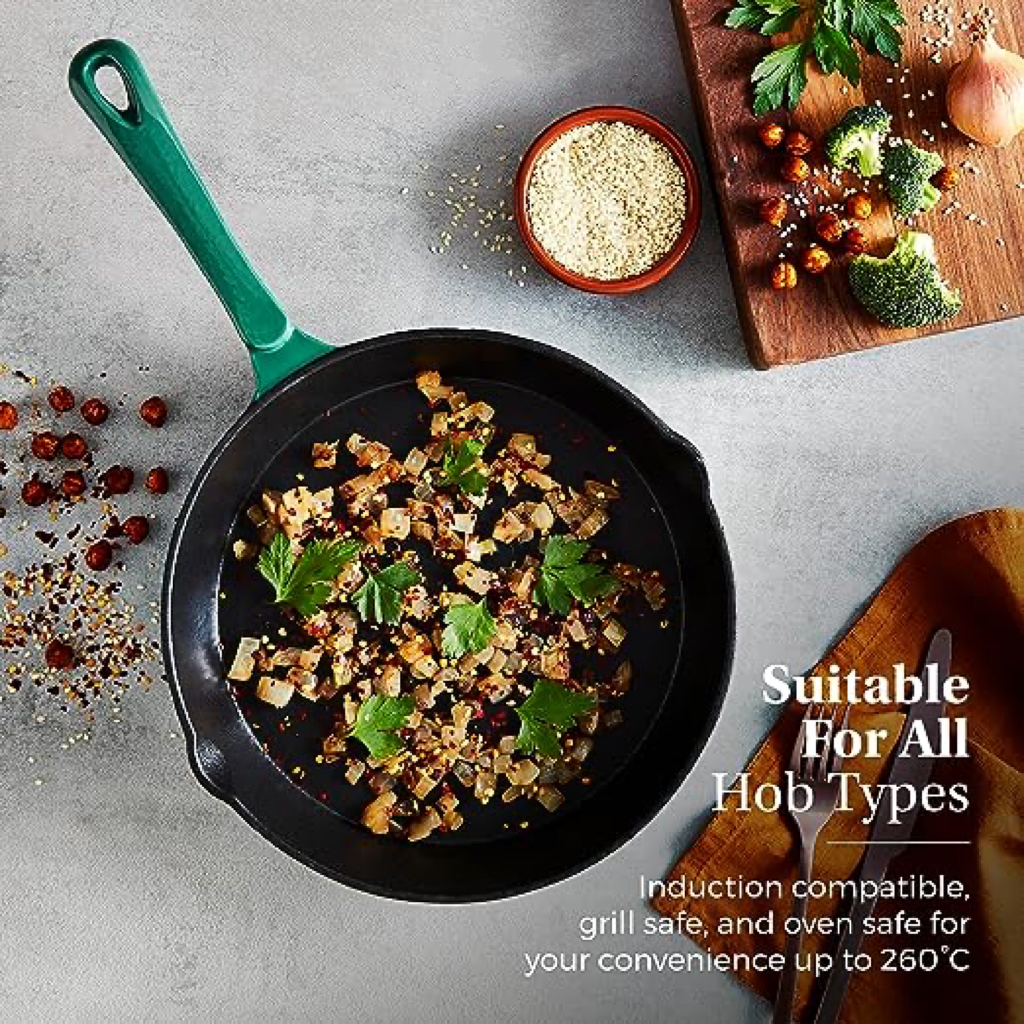

Difference Between A Skillet And Sauté Pan

How to Choose the Best Frying Pan for You

When repairing enamel cookware, it's important to address the problem promptly to prevent further damage. A common way to repair enamel cookware is to use food-safe epoxy or an enamel repair kit. These kits often include a special adhesive that can be used to fill in chipped areas and restore the Enamel cookware's smooth surface.

Why do some professional chefs hate nonstick pans?

CAST IRON FRYING PANS

Below is a table of the distinct features of a frying pan:

Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration

Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration Moreover, the enamel coating resists acidic foods better than bare cast iron, reducing the risk of metallic taste or discoloration cast iron enamel pan set.

cast iron enamel pan set.

cast iron griddle cooking. For pancakes and eggs, it is important to use a little bit of oil or butter to prevent sticking. For meats, it is best to let them sit on the griddle without moving them for a few minutes to achieve a perfect sear.

Medium Cast Iron Skillet

classic cast iron skillet. They are also easy to find and can be passed down through generations, making them a timeless kitchen staple.

classic cast iron skillet. They are also easy to find and can be passed down through generations, making them a timeless kitchen staple. Moreover, the large cooking area is ideal for preparing family-sized meals or multiple dishes simultaneously Moreover, the large cooking area is ideal for preparing family-sized meals or multiple dishes simultaneously

Moreover, the large cooking area is ideal for preparing family-sized meals or multiple dishes simultaneously Moreover, the large cooking area is ideal for preparing family-sized meals or multiple dishes simultaneously cast iron griddle for gas stovetop.

cast iron griddle for gas stovetop.