a dredge pump factories

Latest articles

Pumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read MoreIf you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read MoreConsider the pump components

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read MoreAIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read MoreSlurry Pump

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read MoreSlurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read MoreConsider the impeller. Slurry pumps must have thicker vanes than water pumps to prevent wear. Due to the increased thickness, there will be fewer vanes, otherwise the passages will be too narrow and will affect the performance of the pump. The impeller should have a large enough passage so that the largest solid particles can pass through without clogging.

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read MoreThe basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read MoreApplications

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read Morereduce the discharge pressure of the pump to the lowest possible point, and.

a dredge pump factories...

a dredge pump factories 【a dredge pump factories】

Read More

Popular articles

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Because of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

- The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

- Submersible Slurry Pump

- Slurry pump considerations

Latest articles

-

Many types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

-

Larger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

-

A slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

-

Lifetime use

-

The rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

-

What is slurry?

Links

Choosing the Right Runner Wheels

6262 is highly weldable and often strengthens in aging process.

- Cast iron spears are known for their sharp, pointed tips that can easily penetrate through armor and flesh. The material used to make these spears, cast iron, is a type of iron that has been melted and poured into a mold to create a solid form. This process creates a strong and sturdy weapon that can withstand heavy impact and prolonged use.

- Once you have the new rollers, carefully attach them to the door, aligning them with the holes. Make sure they're securely fastened but not overly tightened, which could cause stress on the door. If your new rollers have different adjustments, familiarize yourself with them to fine-tune the door's movement.

These two types of fencing are made from different materials (obviously) and are also constructed differently.

Bright Dip Anodizing

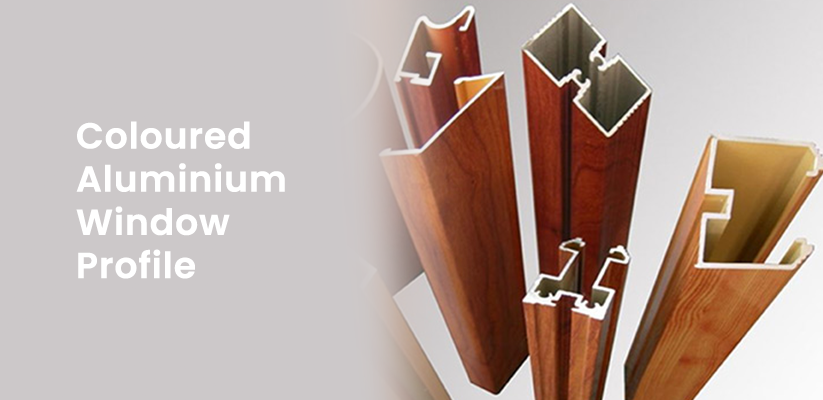

Sliding window profiles can be used in both residential and commercial buildings, and are ideal for spaces that cannot be opened outward. Its biggest feature is the use of sliding type opening method, not only beautiful, but also has a better security and sealing. Generally speaking, the use of aluminum alloy materials sliding window profiles in addition to strong, durable, beautiful and other characteristics, but also has good thermal insulation properties, can play a role in heat preservation, sound insulation.

Aluminum Door & Window Frame Profile Series

Facts About Wrought Iron Fence

Wrought iron fence is a heavy fencing material made up of gauge square tubing for its vertical pickets and punched channel for its horizontal rails. If you are looking for a heavy-duty fence, a wrought iron fence is the fence for you. This fencing is great for high security settings and a great fence to install if you expect much wear and tear. It is a very beautiful fence. Wrought iron fencing is best installed on level terrain or a retaining wall. Typical wrought iron panels are 48” high X 96” wide, which means that its panels are wider than most aluminum fencing. Panels also weigh about 47 pounds each, making it a heavy material to work with, but it also means a highly sturdy fence once installed. Wrought iron comes only in a black powder coated finish. Wrought iron also requires a bit of maintenance, as it will eventually rust over the years when exposed to the outside environment.

Selling to Artists or Crafters

Here are other vital reasons, which make aluminum material the most suitable for making windows and door profiles;

The charm of decorative wrought iron pieces lies in their rich history, exquisite craftsmanship, and timeless appeal. They serve as a testament to the skill and artistry of the blacksmith, transforming functional items into beautiful works of art. As trends come and go, wrought iron remains a staple in design, celebrated for its durability and aesthetic versatility. Whether enhancing a garden, adding elegance to an entryway, or creating a unique focal point in interior decor, decorative wrought iron pieces continue to capture the attention and admiration of many. Embracing wrought iron in design not only pays homage to centuries of craftsmanship but also enriches our surroundings with beauty and character.

Durability and Strength

Additionally, aluminum profile windows are also energy-efficient. They can be fitted with double or triple glazing, which helps to reduce heat loss and improve insulation in a building. This can lead to lower energy bills and a more comfortable indoor environment.

Furthermore, it easy to strengthen it by heat treatment by placing it at a temperature of at least 320° F for several hours.

At the end of the day, both fences are fantastic ones. But if you are planning to install your own fence to save time and money, I say go with aluminum as it’s a great product and one of the easiest to build if you’ve never installed a fence before!

Some of the commonly used ways include the following;

Wrought iron’s density and weight make it a valuable recycling material. Prices for scrap metal fluctuate, so check current rates and consider selling the iron when prices are favorable to maximize your return.

The Elegance and Functionality of Metal Gate Door Knobs

metal lock box with slot. Its very presence is a deterrent, conveying a message to all who lay eyes upon it here lies something of great value, something that is guarded zealously. Even before one attempts to open it, there is a palpable sense of respect for the sanctity of its contents. It is a silent sentinel, standing vigilant against the shadows of potential threats.

metal lock box with slot. Its very presence is a deterrent, conveying a message to all who lay eyes upon it here lies something of great value, something that is guarded zealously. Even before one attempts to open it, there is a palpable sense of respect for the sanctity of its contents. It is a silent sentinel, standing vigilant against the shadows of potential threats.