china drainage and sewage pump manufacturer

Latest articles

Another way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read MoreWhen the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read MoreLarger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read MoreLarger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read MoreFirstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read MoreSlurry Pump

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read MoreChoosing the right slurry pump

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read More>Dredge Pump

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read MoreCaution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

china drainage and sewage pump manufacturer...

china drainage and sewage pump manufacturer 【china drainage and sewage pump manufacturer】

Read More

Popular articles

- As the slurry is collected at the bottom of the tower, more rubber lined pumps are required to transfer the slurry to storage tanks, tailings ponds, waste treatment facilities or filter presses. Depending on the type of FGD process, other pump models are available for slurry discharge, pre-scrubber recovery and catch basin applications.

- In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

- Underwater installation

- The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

- method and level of design reach international advanced level. The company has the first-class pump performance

- Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

Latest articles

-

Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

-

There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

-

For example.

-

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

-

Types of damage to slurry pumps

-

A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

Links

- How to Incorporate 108 by 20 Fabric into Your Home Decor

Meanwhile, if you’re shopping on a budget and believe silky smooth sheets are non-negotiable, then 100% cotton sheets may be a more preferable option. After all, their lower price tag can make up for the frequent anticipated changes through the years. Be sure though that your cotton sheets are made purely what’s on the label for you to fully realize the benefits for yourself.

Linen’s temperature-regulating and hypoallergenic qualities make it a perfect fit for Singapore’s tropical climate, and while linen sheets may be rough at first, the fabric only gets better over time. With enough machine washing cycles, you can recoup the cost in no time.

Lyocell is similar to viscose in that it is a regenerated cellulose fabric, but is made with a more eco-friendly process. TheU.S. Federal Trade Commissiondefines lyocell as rayons “composed of cellulose precipitated from an organic solution in which no substitution of the hydroxyl groups takes place and no chemical intermediates are formed” — essentially meaning it does not use the harmful chemical solvents normal viscoses use. Lyocell production also results in little waste product, but it is still relatively energy intensive.

- Duvet fill weight is typically measured in grams per square meter (gsm) or ounces per square yard (oz/sq yd). It refers to the total weight of the filling material within the duvet, which directly correlates with the warmth and thickness of the bedding. A higher fill weight indicates a denser and heavier duvet, providing more insulation and warmth. Conversely, a lower fill weight suggests a lighter and less insulating duvet, suitable for warmer climates or personal preferences.

Both linen and cotton make excellent bedding fabrics and share quite a few similarities — most notably their water-absorbent qualities and that refreshing, airy feeling. But there are quite a few differences as well, and being aware of them can make it easier for you to choose between the two.

To complete the look, consider adding a bedskirt to hide the space under your bed for a clean, uncluttered look. This accessory can also add a decorative touch, especially if it has frills or ruffles.

What is the best way to select the best Duvet Cover?

Flannel:Flannel is a material most people are likely familiar with from flannel shirts, but it is also a material used for bedding. Traditionally only made with wool, flannel is now made with a variety of materials. Cotton and polyester are the most common.

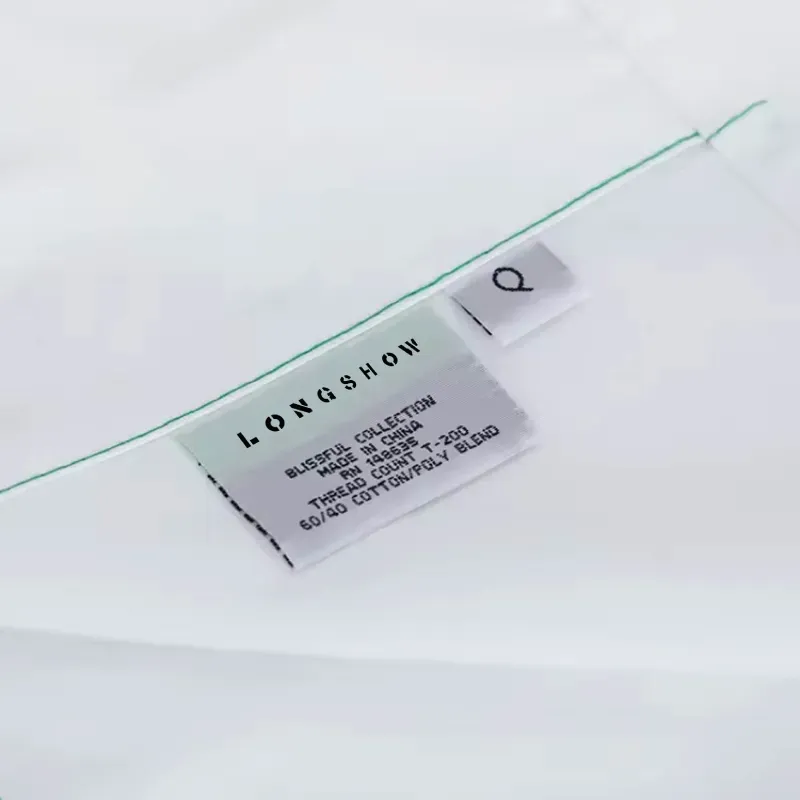

Bed linen can be made from a variety of materials, including cotton, linen, silk, and synthetic blends. The thread count, which refers to the number of threads per square inch of fabric, is a crucial factor in determining the quality and feel of the material. Higher thread counts generally indicate softer, more durable bed linen, with 300-600 thread count being a benchmark for quality.

In addition to material, bedding design is also an important consideration. Whether you prefer a classic, timeless look or a more modern, sleek aesthetic, high-quality bedding are countless design options to choose from.

Microfiber Sheets Sweaty

Budget-friendly and easier to care for

Their radiant shine adds a touch of glamour, while the can elevate the overall ambiance, transforming your sleeping space into a sanctuary of luxury Their radiant shine adds a touch of glamour, while the can elevate the overall ambiance, transforming your sleeping space into a sanctuary of luxury

Their radiant shine adds a touch of glamour, while the can elevate the overall ambiance, transforming your sleeping space into a sanctuary of luxury Their radiant shine adds a touch of glamour, while the can elevate the overall ambiance, transforming your sleeping space into a sanctuary of luxury high thread count satin sheets.

high thread count satin sheets.In addition to the yarn count, the hotel sheets fabric used is also crucial. Cotton is the most popular choice for hotel sheets because of its breathability, softness, and durability. Egyptian or Pima cotton is often favored for its long fibers, which make hotel sheets finer, smoother, and more luxurious. Not only are these high-quality cotton hotel sheets comfortable, they stand up to frequent washing and retain their softness over time.

Linen bed sheets are valued for their natural, textured feel and ability to stay cool in warm weather.

JERSEY KNIT While Jersey knit sheets are still made from either natural or synthetic cotton, where they differ is the way they are produced. Instead of being woven like traditional cotton sheets, they are knitted. This gives the sheets a natural stretch and extra warmth. Keep in mind that jersey knit sheets do not have a thread count. Instead, the quality of the sheet can be measured by its weight per square yard.

Flannel Sheets Thread Count

Throw

Luxury throw blankets are small decorative blankets, often with trim or fringe, that are used for extra warmth, decoration, or as a covering when lounging on top of the bed. It is normally folded at the foot of the bed, on top of any other bedding.