oem 4x3dd slurry pump factory

Latest articles

A slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read MoreSlurry pump vs mud pump

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read MoreIt is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read MoreAIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read MoreSlurry pump power adjustment

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read MoreImproved flow control

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read MoreWhat is a slurry?

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read MoreApplications

oem 4x3dd slurry pump factory...

oem 4x3dd slurry pump factory 【oem 4x3dd slurry pump factory】

Read More

Popular articles

- There is a science behind the design of a , slurry pump, , based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- A typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

- The solution is to choose a >heavy duty slurry pump and, just as importantly, to use a custom built unit with replaceable parts. At Aier Machinery, building your custom slurry pump is one of our areas of expertise. We design your slurry pump to your specifications and application.

- To reduce wear, reduce the pump discharge pressure to the lowest possible point.

- Dredge pumps are designed to transfer large quantities of fluids and solids.

- What is the optimum seal arrangement for the application?

Latest articles

-

Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

-

Aier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

-

Other manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

-

sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

-

What is slurry?

-

Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

Links

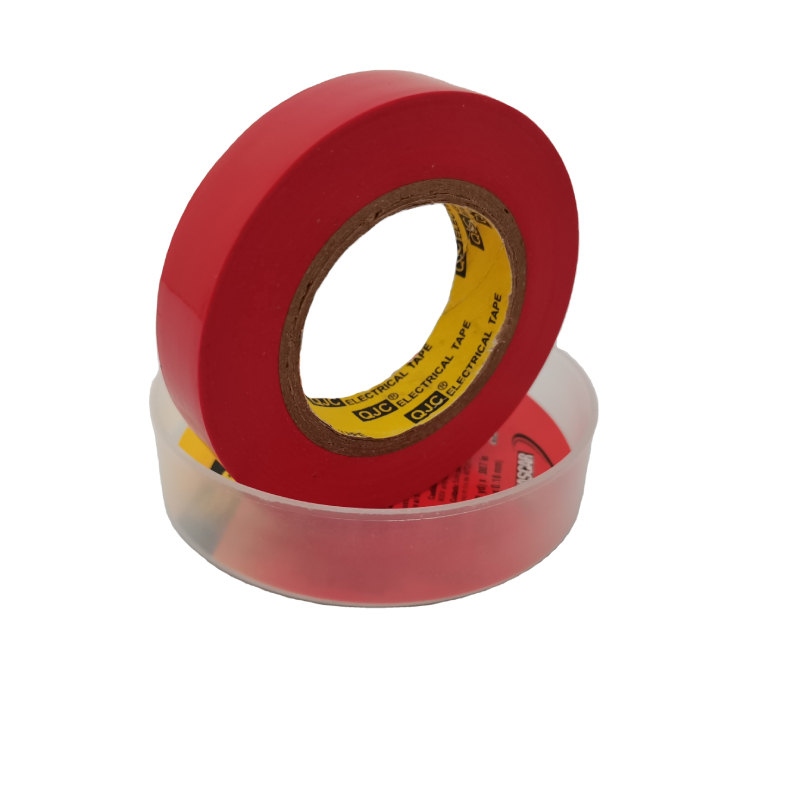

- Provides an immediate, long-lasting, watertight seal

- In conclusion, safety floor tape is an essential tool for promoting workplace safety in industrial settings. Its high visibility, clear communication of safety information, and durability make it an effective solution for marking potential hazards and guiding employees to safer work practices. By investing in safety floor tape, employers can create a safer work environment for their employees and reduce the risk of accidents and injuries.

But there are some types that can withstand temperatures up to 200°C.

6. Test the seal After the tape has cured, test the seal by running water over the surface. Check for any leaks or gaps in the tape. If needed, reapply additional layers of tape to ensure a secure seal.

Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures

Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures Unlike traditional vinyl or paper tapes, this tape is much more resistant to wear and tear, making it a great choice for applications where the tape will be subjected to rough handling or extreme temperatures