high quality open impeller slurry pump

Latest articles

Pumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read MoreA slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read MoreSubmersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read MoreWhat style of pump is suitable?

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read MoreHydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read MoreThe rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read MoreAier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read More>Slurry Pump

high quality open impeller slurry pump...

high quality open impeller slurry pump 【high quality open impeller slurry pump】

Read More

Popular articles

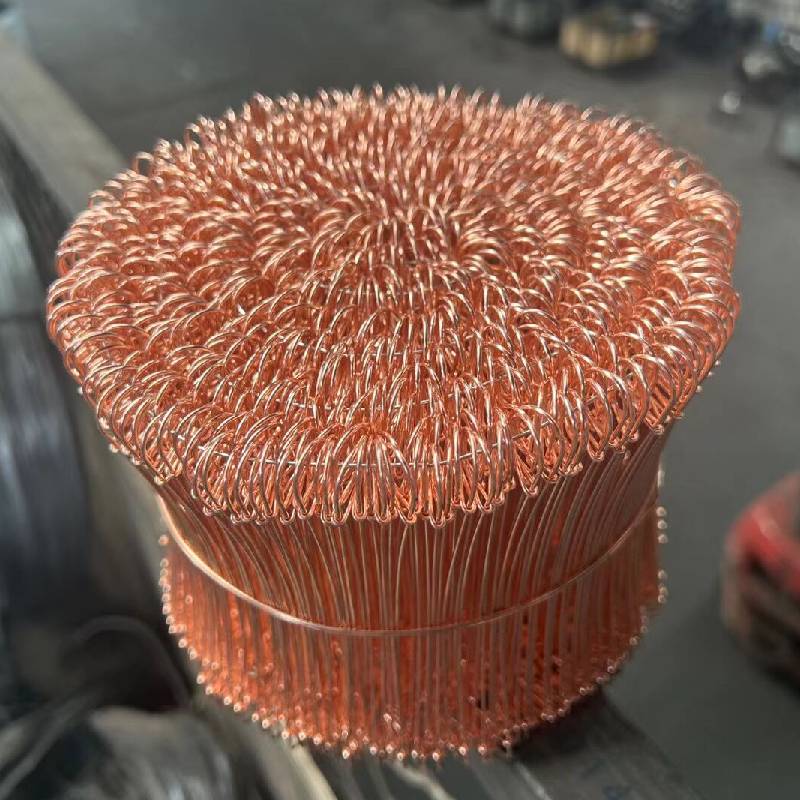

- When slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

- Selecting a dredge pump

- For example.

- Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

- Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

- What is a dredging pump?

Latest articles

-

Find a professional slurry pump supplier

-

A target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

-

Centrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

-

How to choose a slurry pump?

-

Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

-

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.