Athletes and trainers often use it for injury prevention and support Athletes and trainers often use it for injury prevention and support

Athletes and trainers often use it for injury prevention and support Athletes and trainers often use it for injury prevention and support insulation cotton tape. Its breathable cotton base provides a comfortable, non-irritating wrap for muscles and joints, while the adhesive ensures it stays in place during rigorous physical activity.

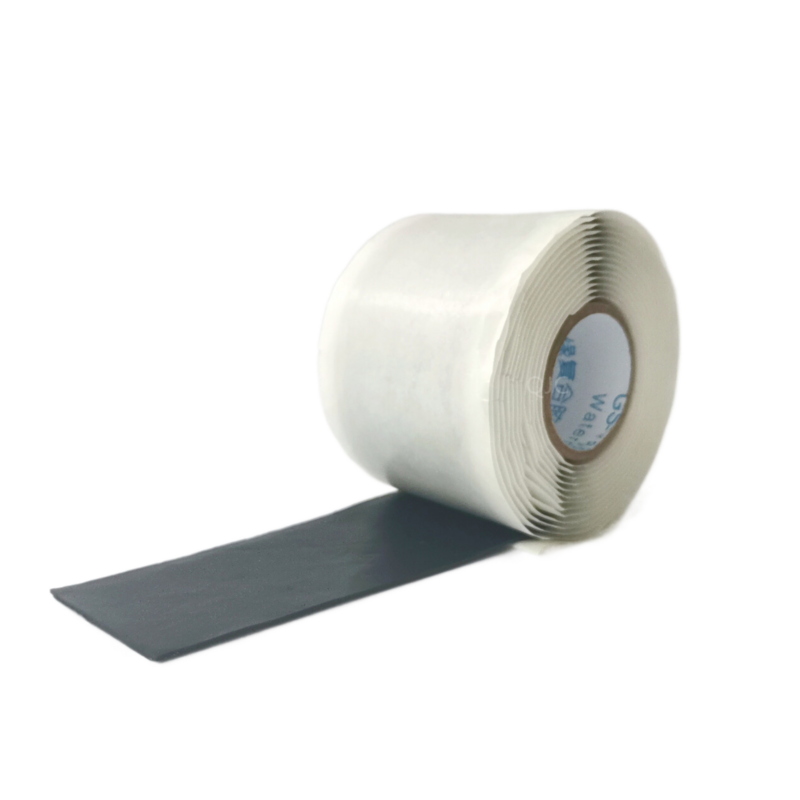

insulation cotton tape. Its breathable cotton base provides a comfortable, non-irritating wrap for muscles and joints, while the adhesive ensures it stays in place during rigorous physical activity. It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure

It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure It is made from materials that are specifically designed to prevent the flow of electricity, ensuring that wires remain safe and secure

Moreover, its flexibility allows it to conform to the contours of the vehicle, providing a snug and secure fit around the wires Moreover, its flexibility allows it to conform to the contours of the vehicle, providing a snug and secure fit around the wires

Moreover, its flexibility allows it to conform to the contours of the vehicle, providing a snug and secure fit around the wires Moreover, its flexibility allows it to conform to the contours of the vehicle, providing a snug and secure fit around the wires