froth slurry pump suppliers

Latest articles

The Company Adopts Advanced Computer Aided Engineering Software

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read Moremethod and level of design reach international advanced level. The company has the first-class pump performance

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read MoreConsider the pump components

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read MoreThese mud pumps can pump not only sand, but also more mud. They are very effective in pumping all forms of mud, gravel, concrete, slurry, slush, etc.

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read MoreAier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read MoreThe selection of a dredge or , slurry pump, can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read More>Slurry Pump

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read MoreIf you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

froth slurry pump suppliers...

froth slurry pump suppliers 【froth slurry pump suppliers】

Read More

Popular articles

- One of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

- In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

- For more information about this new and improved pump, please contact us.

- Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

- factors-to-consider-when-choosing-a-slurry-pump

- The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

Latest articles

-

Dredge Pump

-

As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

-

Slurry Pump

-

Choosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

-

- By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

-

- Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

Links

Hot-dip galvaniserad gitter - En hållbar lösning för olika applikationer

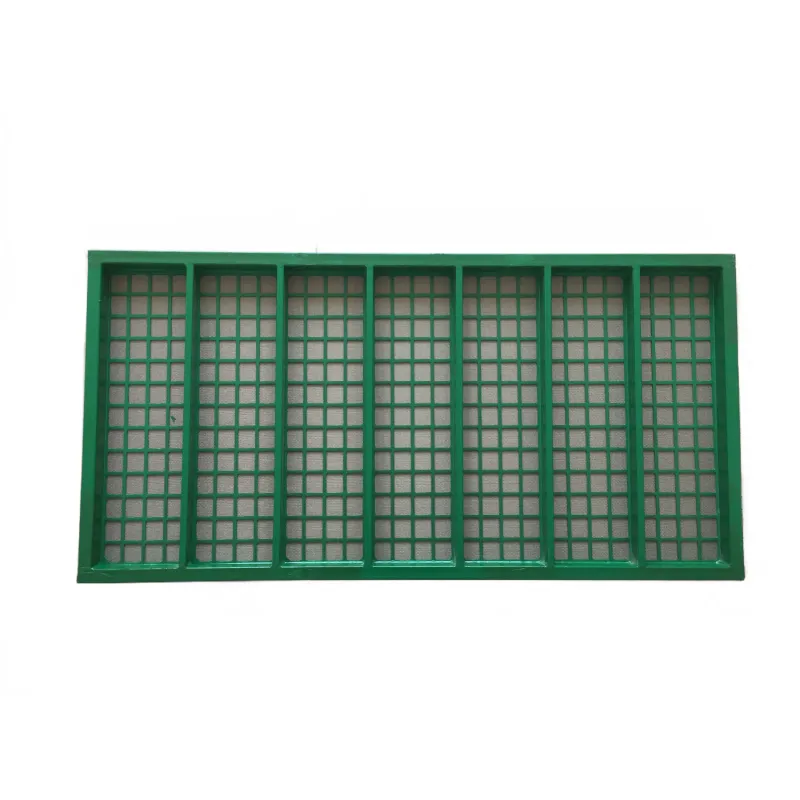

The design of shaker screens varies depending on the application and material being processed. Some screens have a single deck, while others have multiple decks to achieve different size separations. The screen media itself can be made of various materials, such as wire mesh, polyurethane, or rubber, depending on the required durability and separation efficiency.

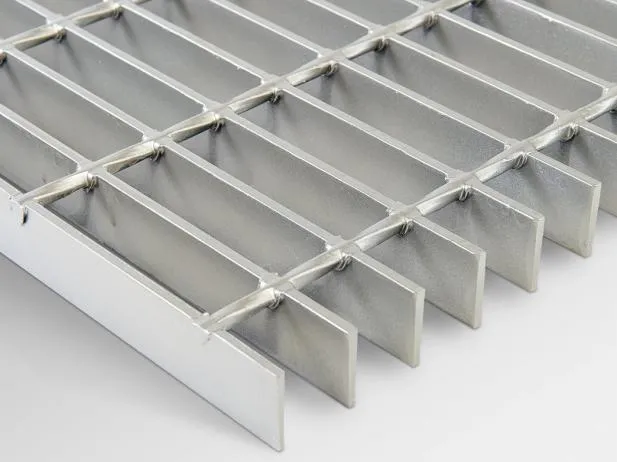

Moreover, heavy steel grating contributes to improved safety standards in various settings. Its slip-resistant surface, along with the ability to see through the grating, enhances visibility and reduces the risk of accidents. This feature is particularly important in environments where visibility is critical, such as in factories or near machinery.

1% Bar Grating Yapısal Güç ve Tasarımdaki Önemi

In conclusion, heavy duty steel grating is an essential material across multiple industries owing to its exceptional strength, versatility, and safety features. As businesses continue to prioritize efficiency and safety, the demand for heavy duty steel grating will only increase, solidifying its role in industrial applications for years to come. Whether it's for flooring, walkways, or drainage systems, heavy duty steel grating represents a reliable solution to meet the rigorous demands of modern industry.

Manufacturing Process

3. Safety The open design of steel grating allows for effective drainage, reducing the risk of water accumulation and slippery surfaces. This enhances safety in industrial environments where spills may occur.

Enfin, le treillis en acier 19W4 est également une solution respectueuse de l'environnement. Durable et recyclable, l'acier est une option de choix pour les constructions durables. Son utilisation contribue à réduire les déchets et à promouvoir une construction plus verte.

Stainless steel is one of the most hygienic materials, as it does not support the growth of bacteria. In addition, cleaning is effortless.

Advantages Of Using Carbon Steel Bar Grating For Heavy Loads

In addition to its strength, heavy steel grating offers excellent drainage capabilities. The open design allows for water, debris, and other materials to pass through, preventing accumulation that can lead to slips and falls. This drainage feature makes heavy steel grating an attractive option for walkways and outdoor platforms, especially in areas exposed to rain or snow.

Importance of Thickness

ការងារវិជ្ជាជីវៈ និងការសម្រទាប់

In conclusion, understanding the various sizes and types of steel grating is essential for making informed decisions in construction and industrial applications. Properly sized steel grating can enhance safety, improve functionality, and bring aesthetic value to any project. As industries continue to evolve and demand more innovative solutions, the adaptability and reliability of steel grating remain paramount. Always consult with a professional to choose the right dimensions and style that best meet your specific requirements. By doing so, you can ensure that your project stands the test of time, efficiency, and safety standards.

Nəticə etibarilə, polad drenaj qapaqları müasir inşaat və infrastruktura mühüm töhfə verir. Onlar suyun yığılmasını, daşınmasını, təmizlənməsini və ətraf mühitin mühafizəsini təmin edə biləcək güclü vasitələrdir.

Environmental sustainability is another significant factor to consider. Steel is highly recyclable, making steel grid walkways an eco-friendly choice. Many manufacturers use recycled materials in their products, contributing to a reduced carbon footprint. Investing in steel walkways aligns with the growing emphasis on sustainable practices in construction and infrastructure development.

In commercial spaces, open grating can be used for aesthetic purposes, creating visually appealing elevated walkways or terraces that do not block natural light or views. Moreover, its lightweight and robust nature makes it an excellent choice for temporary structures or installations, such as event staging.

For anyone looking to purchase stainless steel bar grating, it is advisable to obtain quotes from multiple suppliers and to ensure that they are comparing similar grades and specifications. By doing this, consumers can better understand the market and make educated choices that meet both their budgetary and functional requirements.

Shaker screens play a pivotal role in various industries, particularly in mining and aggregate processing. These screens are essential for separating materials based on size, ensuring efficient operation, and maintaining product quality. In this article, we will delve into the details of shaker screens, exploring their design, functionality, types, maintenance, and more.

1. Durability Hot dip galvanized steel grating exhibits remarkable strength and resistance to harsh environmental conditions. The zinc coating acts as a barrier against moisture, chemicals, and atmospheric pollutants, significantly extending the lifespan of the material.

The thickness of steel grating also plays a critical role in its applications. Typically, thickness ranges from 1/2 inch to 1 inch, with heavier grating often used in high-traffic areas or environments subject to heavy loads. For example, a 1-inch thick grating is ideal for industrial operations, where forklifts and trucks are common, while a 1/2 inch thick option may be sufficient for pedestrian walkways.

steel grating sizes

नयाँ प्रविधिहरूको आगमनले हेलीडेक नेटवर्कमा पनि परिवर्तन ल्याएको छ। आधुनिक नेटवर्कहरूले वास्तविक समयमा डेटा संकलन गर्न र विश्लेषण गर्न सक्षम बनाउछन्, जसले हवाई ट्राफिकको व्यवस्थापनमा सुधार ल्याउँछ। यस प्रणालीले चालक दल र भूमि प्रबन्धकहरूको बीचमा सम्पर्क र समन्वयलाई सजिलो बनाउँछ, जसले दुर्गम स्थानमा पनि प्रभावकारी रूपमा काम गर्न सक्षम बनाउँछ।

helideck net

In commercial construction, this type of grating is often implemented in balconies, stairways, and as infill panels, providing both safety and a stylish appearance. Architects appreciate its aesthetic versatility, as bar grating can be designed to blend seamlessly with modern architectural elements.

Die Einsatzmöglichkeiten des A325%-Gitters sind vielfältig. In der Spektroskopie, einem Verfahren zur Analyse der chemischen Zusammensetzung von Materialien, kommen diese Gitter häufig vor. Sie ermöglichen es Wissenschaftlern, das Licht, das von einer Probe emittiert oder reflektiert wird, in seine spektralen Komponenten zu zerlegen. Dies ist von entscheidender Bedeutung für die Identifizierung von chemischen Substanzen und die Untersuchung ihrer Eigenschaften.

a325 grating

Grating Leggero Innovazioni e Applicazioni

4. Size and Configuration Standard sizes of stainless steel bar grating are usually less expensive than custom-made options. For larger projects requiring unique configurations, the price may rise significantly due to increased fabrication complexities.

Agriculture is another sector where shale screens find valuable applications. They are used in irrigation systems to filter water, preventing the blockage of pipes and nozzles by sediment and other particles. This ensures efficient water distribution and optimal crop growth.

Esthétiquement, les passerelles en acier inoxydable apportent une touche de modernité et de sophistication. Leur finition lisse et brillante attire le regard et s’intègre parfaitement dans des environnements urbains ou naturels. Utilisées dans des parcs, des espaces publics ou des complexes commerciaux, elles deviennent des points focaux qui améliorent l'expérience visuelle des utilisateurs. Les éclairages intégrés peuvent également mettre en valeur la structure pendant la nuit, transformant la passerelle en un monument scintillant.

갈바니즈드 강철 그레이트를 구입할 때 고려해야 할 몇 가지 사항이 있습니다. 먼저, 제품의 두께와 크기를 확인해야 하며, 필요한 하중을 견딜 수 있는지 평가해야 합니다. 또한, 제조업체의 신뢰성과 품질 보증 정책도 중요합니다. 이를 통해 고품질의 강철 그레이트를 구매할 수 있습니다.

Сланцевые экраны представляют собой важнейшую составляющую оборудования для бурения в нефтегазовой отрасли. Они используются для отделения твердых частиц от жидкости, что позволяет обеспечить чистоту бурового раствора и повысить эффективность процесса бурения. В последние годы наблюдается рост спроса на шейкеры и соответствующие экраны, что связано с увеличением объема добычи сланцевой нефти и газа.

Endelig er økonomien en vigtig faktor. Tykkere stålriste er ofte dyrere at producere og transportere. Det er derfor nødvendigt at finde en balance mellem omkostninger og funktionelle krav. I mange tilfælde kan det betale sig at investere i en tykkere rist, hvis det betyder, at man undgår hyppige reparationer eller udskiftninger i fremtiden.

The Foundation of Shale Shaker Screen Mesh

The price of floor grating largely depends on the material used. Common materials include steel, aluminum, fiberglass, and plastic. Steel grating is typically the most economical option, often used in industrial applications due to its strength and resistance to heavy loads. Aluminum grating, while slightly more expensive, is lightweight and resistant to corrosion, making it suitable for outdoor and marine environments. Fiberglass grating is ideal for corrosive environments where durability is essential. Although it generally comes at a higher price, its longevity can offset initial costs.

Working Principle: During the drilling process, the drilling fluid, which is a mixture of water, clay, and other additives, is circulated through the drill string to lubricate the bit and carry cuttings to the surface. Upon reaching the surface, the fluid is fed into the shale shaker, where the screen mesh separates the solid particles from the fluid. The cleaned fluid is then recirculated back into the drilling system.

Izgaraların boyutları, suyun debisine ve tahliye edilmesi gereken alanın büyüklüğüne bağlı olarak değişir. Örneğin, büyük miktarda suyun birikmesi beklenen yerlerde, daha geniş ve derin ızgaralar faydalı olurken, daha az su akıntısının olduğu alanlarda standart boyutlar yeterli olacaktır. Ayrıca, ızgaraların malzeme kalitesi ve tasarımı da, suyun hızlı bir şekilde tahliye edilmesini etkileyen önemli faktörlerdir. Paslanmaz çelik, alüminyum ve polimer gibi dayanıklı malzemelerden üretilen ızgaralar, uzun ömürlü ve etkili bir çözüm sunar.