high quality ash slurry submersible pump manufacturers

Latest articles

Horizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read MoreSlurry Pump

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumps help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read MoreExamples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read MoreWhat is Heavy Duty Slurry Pump?

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read More- Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read More>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read MoreTo find out more about Aier slurry Pumps, please >contact us.

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read MoreSlurry Pump

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read MoreAnother important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

high quality ash slurry submersible pump manufacturers...

high quality ash slurry submersible pump manufacturers 【high quality ash slurry submersible pump manufacturers】

Read More

Popular articles

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

- To find out more about Aier slurry Pumps, please >contact us.

- Series of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

- WL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

- Working principle

- Slurry pump vs mud pump

Latest articles

-

Pump selection for FGD

-

A slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

-

Many types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

-

Slurry Pump

-

Make sure you follow the basic rules of pump piping.

-

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

Links

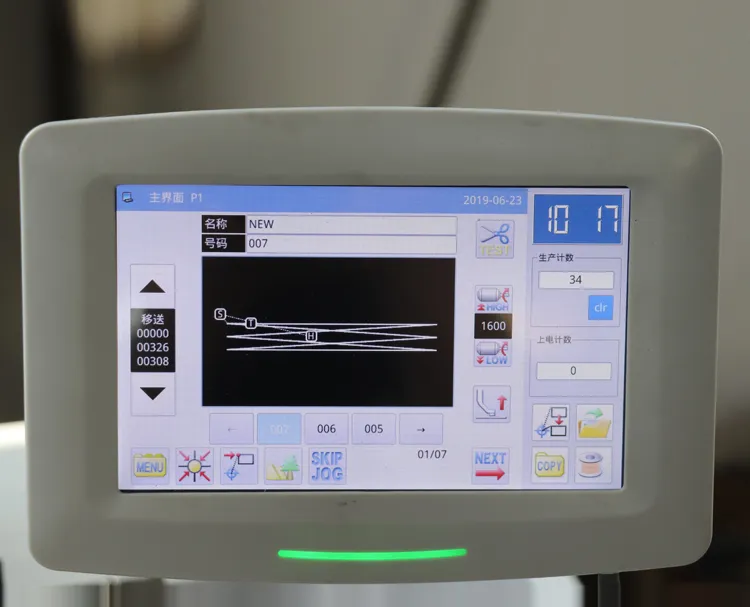

Another key feature is the adjustable stitch length, which provides versatility for different sewing projects. Operators can easily modify the stitch length, allowing for intricate designs or sturdy seams as needed. Additionally, many walking needle machines come equipped with various presser feet attachments, enabling users to create decorative stitches or tackle specific tasks such as quilting or binding.

2. Thread Opt for strong, heavy-duty thread like polyester or nylon. These threads are less likely to break under strain and will hold up against the robust fabric.

What is a Lock Stitch?

5. Ease of Adjustment Many industrial sergers come equipped with advanced tension control and stitch length settings, allowing operators to quickly adjust their settings based on fabric type and desired stitch characteristics.

- Sewing is a timeless craft that has been enjoyed by countless individuals for generations. Whether you're a seasoned seamstress or a novice, having a reliable sewing machine is essential. If you're in the market for a sewing machine that can handle heavy-duty projects, a refurbished heavy-duty sewing machine may be just what you need.

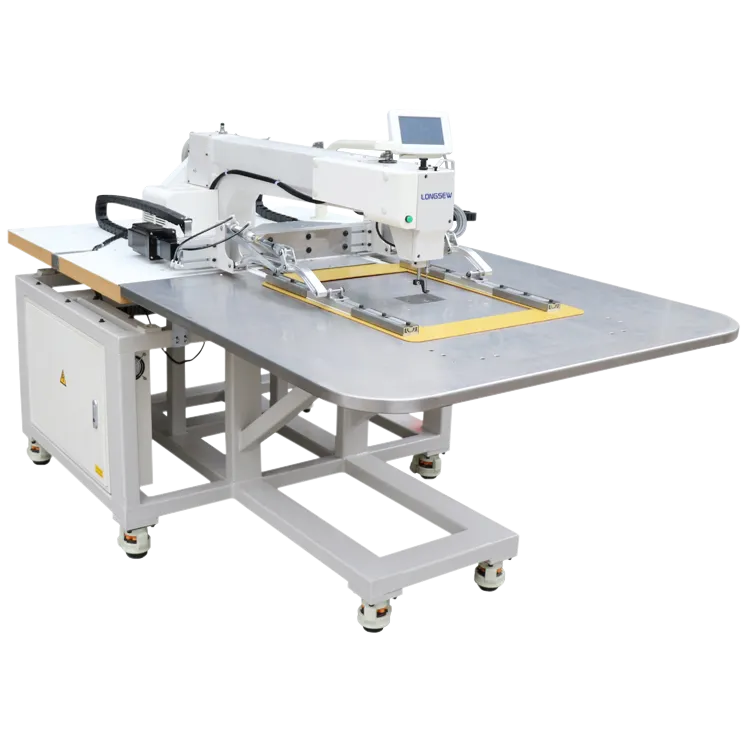

Whether you're a seasoned quilter, a professional seamstress, or a hobbyist looking to expand your sewing skills, a long arm stitching machine is a valuable tool to have in your arsenal. Its extended workspace, increased visibility, versatility, and advanced features make it a must-have for anyone who wants to take their sewing projects to the next level.

1. Brother CS7000X This versatile model is excellent for beginners and experienced sewers alike. It features 70 built-in stitches, a large LCD display, and an automatic needle threader. It also includes a wide table, perfect for larger projects, making it a fantastic choice for quilting.

For novice sewists, mastering the sewing machine can seem daunting. An automatic bobbin winder simplifies one of the more complex aspects of sewing. It helps beginners build confidence in their skills, allowing them to spend more time learning the art of sewing rather than fumbling with bobbins. This feature can enhance the overall learning experience and encourage more people to take up sewing as a hobby.

Exploring the World of Auto Sewing Revolutionizing Textile Production

3. Brand Reputation Research brands known for their reliability and support. Popular brands often have established service networks, which can be crucial for maintenance and repairs.

Overall, this machine has great reviews. Users rave about the ease of use and how easy it is to learn to use it. Users were able to sew denim, thick purse straps, and other heavier materials with no problems.

In the realm of sewing, particularly for leatherwork, the choice of the machine can make all the difference in achieving professional-quality results. One of the best options for leather sewing enthusiasts and professionals alike is the walking foot leather sewing machine. Known for its robust design and unique feeding mechanism, this type of sewing machine offers unparalleled benefits when it comes to crafting items from thick or slippery materials.

In the world of textile and garment production, the double needle sewing machine stands as a pivotal innovation that has transformed the way garments are constructed. This machine is a specialized sewing tool that utilizes two needles working simultaneously to create parallel rows of stitching. It is particularly renowned for its efficiency and precision, making it a favorite in both industrial and home sewing environments.

Recycled Materials: In textiles, recycled materials may include repurposed denim, reclaimed leather, or fabrics made from recycled plastics or other sustainable sources, such as old T-shirts made into quilts. Fabrics previously processed or worn can be denser or more difficult to manipulate when crafted with recycled materials, necessitating a heavy-duty sewing machine to ensure efficient and durable needlework.

3. Adjust Tension Settings Depending on your machine, you may need to adjust the tension settings to ensure that the stitches are even and secure.

Moreover, the built-in walking foot saves time and enhances convenience. Traditionally, sewing enthusiasts would have to pause their work to switch between different presser feet depending on the fabric type. With a sewing machine equipped with a built-in walking foot, users can transition smoothly between fabric types without interrupting their workflow. This feature encourages creativity and experimentation, as sewists can confidently tackle a wider range of projects without the fear of poor results.

The Versatility of the Dressmaker Zig Zag Sewing Machine

container bag sewing machine. This is important in the production process, where time is of the essence, and a high volume of bags needs to be sewn in a short amount of time. The container bag sewing machine is equipped with a large bobbin and thread capacity, allowing for long hours of uninterrupted sewing.

5. Variety of Stitch Options Many commercial upholstery machines come with multiple stitch options, including straight, zigzag, and decorative stitches. This versatility allows for creativity in design, making it easier to produce unique and appealing upholstery work.