high quality metal liner slurry pump manufacturers

Latest articles

Materials of Construction

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read MoreIf a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read MoreOur firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read MoreMixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read MoreCarbon transfer

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read More- Pumping the final product in a process

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read MoreA quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read MoreCorrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read MoreVertical Slurry Pump

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read MoreSettling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

high quality metal liner slurry pump manufacturers...

high quality metal liner slurry pump manufacturers 【high quality metal liner slurry pump manufacturers】

Read More

Popular articles

- A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

- Conveying medium

- The Difference Between Flushing And Quenching in Slurry Pump Seals

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

- The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

- The length of the piping. The longer the pipe, the more slurry-induced friction the pump needs to overcome.

Latest articles

-

Rubber Lined Slurry Pump

-

Slurry Pump

-

The terms 'flushing' and 'quench' often seem to be confused or misused when discussing seal support schemes for >slurry pumps. As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

-

What is the optimum seal arrangement for the application?

-

- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

-

Sites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

Links

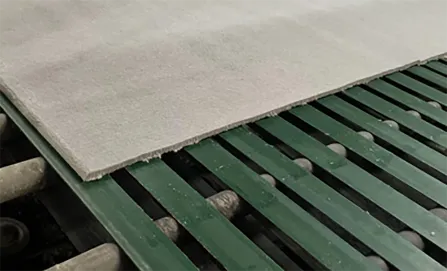

Laminated Gypsum A Comprehensive Overview

Aesthetic considerations should not be overlooked either. A properly designed and installed 600x600 ceiling access hatch can seamlessly blend into the existing ceiling design, maintaining the overall appearance of the space. Many modern hatches come with features such as flush finishes and paintable surfaces, allowing them to be discreetly integrated into a room's aesthetic. This ensures that functionality does not compromise style, a critical balance in contemporary design.

Aesthetic versatility is another compelling reason to consider a hanging ceiling tile grid. Various designs and finishes are available, allowing architects and designers to achieve a wide range of looks. Whether one is aiming for a sleek and modern appearance or a more traditional style, ceiling tiles can be chosen to match any design theme. The ability to swap out tiles easily also means that the aesthetic can evolve over time, offering a flexible design approach that meets changing tastes and preferences.

The Importance of T-Grid Ceilings

3. Cutting If necessary, cut the grid covers to size using appropriate tools. Most grid covers can be easily trimmed to fit.

Importance of Main Tees

Access panels are essential components in building construction and maintenance, serving as gateways to concealed spaces for inspections and repairs. The size of these panels is a crucial factor that enhances their functionality, with various dimensions designed to suit different ceiling applications.

Using ceiling grid bars brings multiple advantages

Versatility Across Applications