casting dredge pump part suppliers

Latest articles

Slurry Pump VS Mud Pump

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read MoreWhen the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read MoreLifetime use

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read MoreUnderwater installation

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read MoreChoosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read MoreWhat is 'slurry'?

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read MoreMetal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read MoreDetermine the nature of the material to be pumped

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read MoreThe impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

casting dredge pump part suppliers...

casting dredge pump part suppliers 【casting dredge pump part suppliers】

Read More

Popular articles

- The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

- The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

- >Slurry Pump

- These conditions include

- To find out more about Aier slurry Pumps, please >contact us.

- As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

Latest articles

-

Repairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

-

>Vertical Slurry Pump

-

Slurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

-

The concentration of solids in the slurry - measured as a percentage of the total volume.

-

Rubber Lined Slurry Pump

-

Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

Links

- The 108x102% Sheet A Journey into the World of Percentage and Mathematics

- To ensure that your sheet set with an 1800 thread count remains in top condition, it's important to follow the care instructions provided by the manufacturer. This may include washing the sheets in cold water, using a gentle cycle, and avoiding the use of harsh chemicals or bleach. It's also recommended to line dry or tumble dry on low heat to preserve the fabric and maintain its softness.

- When it comes to choosing the right washable down alternative comforter, there are a few things to consider. First, think about the size of your bed and the amount of fill you need. A comforter that is too small or too large can be uncomfortable and unsightly. Second, consider the material and construction of the comforter. Look for a comforter that is made from high-quality materials and has a tight construction to prevent clumping and shifting.

When choosing bedsheets, it is important to consider factors such as material, weave, thread count, and care instructions. If softness and warmth are your priority, flannel sheets may be your best choice. For a silky, luxurious feel, satin or satin sheets may be the perfect choice. If breathability and durability are your top priorities, cotton sheets may best suit your needs.

Material

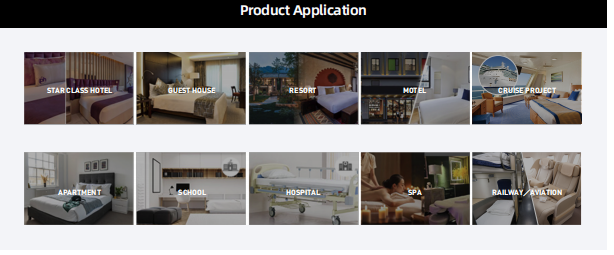

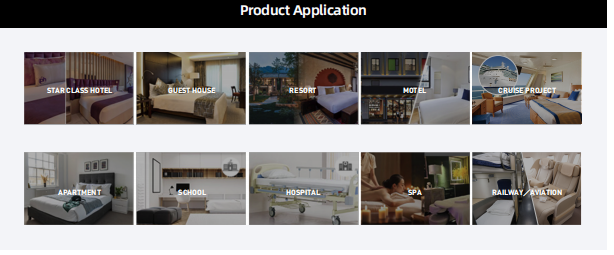

Cot Bedding

Hospital Bedding Supplies

For more details on this ultra-cozy fabric, explore our guides:

Bamboo Bedding

towel sets on sale. Some towels require special washing techniques to maintain their quality. Look for machine washable towels that can be tumble dried for convenience. Low-maintenance options will save you time and effort in the long run.

towel sets on sale. Some towels require special washing techniques to maintain their quality. Look for machine washable towels that can be tumble dried for convenience. Low-maintenance options will save you time and effort in the long run.

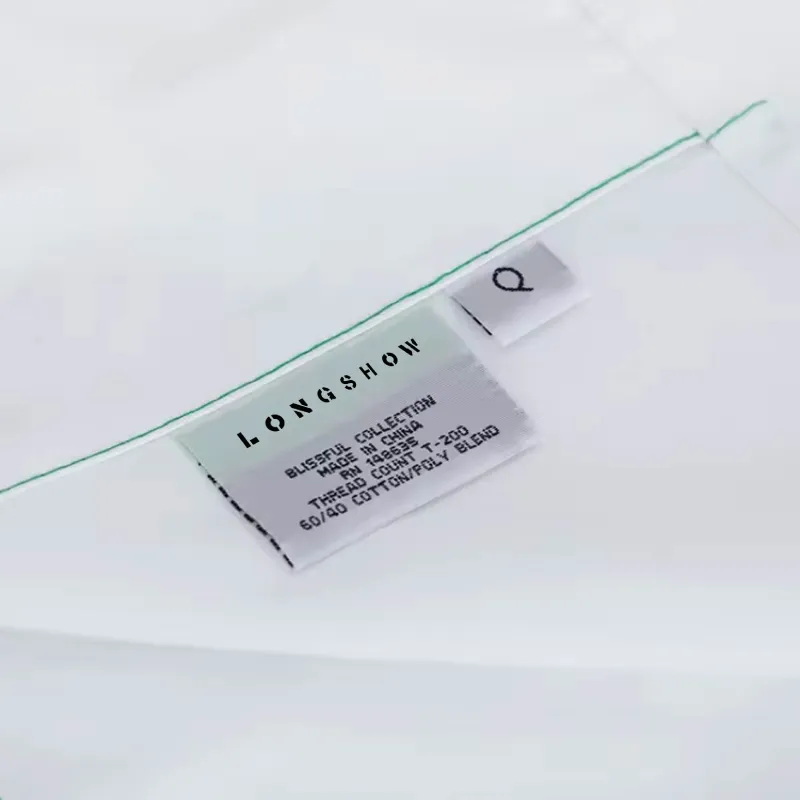

Wholesale hotel T200 percale bed sheet

The waffle pattern adds an extra layer of resilience, enhancing the fabric's strength and resistance to wear and tear The waffle pattern adds an extra layer of resilience, enhancing the fabric's strength and resistance to wear and tear

The waffle pattern adds an extra layer of resilience, enhancing the fabric's strength and resistance to wear and tear The waffle pattern adds an extra layer of resilience, enhancing the fabric's strength and resistance to wear and tear terry cloth waffle robe.

terry cloth waffle robe.A duvet cover is the cloth case that encases your duvet and closes with buttons, snaps, or zippers. It is commonly made of cotton or polyester. It makes washing bedding simpler, gives more design flexibility, and even provides a distinct sensation beneath the covers.

The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey

The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey The feel of crisp, clean sheets can make a significant difference in how well a traveler sleeps, especially after a long journey hotel standard bed sheets. Moreover, the aesthetic appeal of the bedding cannot be underestimated. Well-presented bed sheets in neutral colors with subtle, tasteful patterns can enhance the overall ambiance of the room, contributing to a sense of luxury and refinement.

hotel standard bed sheets. Moreover, the aesthetic appeal of the bedding cannot be underestimated. Well-presented bed sheets in neutral colors with subtle, tasteful patterns can enhance the overall ambiance of the room, contributing to a sense of luxury and refinement.

hospital bed sheets. Hospitals are breeding grounds for bacteria and viruses, so it is crucial that bed sheets are made of materials that are resistant to microbial growth. Many hospitals use antimicrobial bed sheets that are specially treated to prevent the growth of bacteria, helping to reduce the risk of infections spreading between patients.

Hand towels are smaller in size and are mainly used to dry your hands after taking a shower. Hand towels are often placed near bathroom and kitchen sinks for easy access. Hand towels are available in a variety of materials, including cotton, bamboo, and microfiber. Hand towels are designed to be soft and gentle while effectively absorbing moisture.

Additionally, choosing sheets with a higher thread count can provide a more luxurious and durable feel, helping to prevent slipping or shifting during use Additionally, choosing sheets with a higher thread count can provide a more luxurious and durable feel, helping to prevent slipping or shifting during use

Additionally, choosing sheets with a higher thread count can provide a more luxurious and durable feel, helping to prevent slipping or shifting during use Additionally, choosing sheets with a higher thread count can provide a more luxurious and durable feel, helping to prevent slipping or shifting during use sheets without deep pockets.

sheets without deep pockets.