slurry pump wet end parts factory

Latest articles

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read MoreHigh head (i.e. the height to which the pump can move the liquid)

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read More1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read More- Pumping the final product in a process

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read MoreDredge Pump

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read MoreHow much solids damage can the customer tolerate?

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read More>Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read MoreThe frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read More>Dredge Pump

slurry pump wet end parts factory...

slurry pump wet end parts factory 【slurry pump wet end parts factory】

Read More

Popular articles

- Dredge Pump Features

- Improved flow control

- As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

- How much solids damage can the customer tolerate?

- We know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

- Dredge Pump Features

Latest articles

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

-

Step 1

-

1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

-

Series of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

-

The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

-

It is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

Links

- Regular maintenance of your cast iron griddle will ensure that it continues to perform well for years to come. By following these simple cleaning steps after each use, you can keep your griddle in top condition and enjoy perfectly cooked meals every time.

- One of the key benefits of a cast iron flat top grill plate is its versatility. It can be used on various heat sources, including stovetops, ovens, campfires, and outdoor grills, making it a true all-rounder. The flat surface provides ample space for multitasking, accommodating multiple dishes simultaneously. From pancakes and eggs in the morning to stir-fries and burgers at night, the possibilities are endless.

cast iron skillet set.

Cooking on a cast iron griddle is a versatile and enjoyable experience, especially when used on an electric stove. Whether you're preparing a hearty breakfast or grilling a steak for dinner, a cast iron griddle gets the job done with ease. Here are some tips for using a cast iron griddle on an electric stove, poaching eggs on the skillet, and cleaning the skillet afterward.

Nonstick

Before using your bacon press, ensure that your cooking surface, whether it be a skillet, griddle, or grill, is preheated to the desired temperature. Proper preheating helps to achieve an even cook and crispiness.

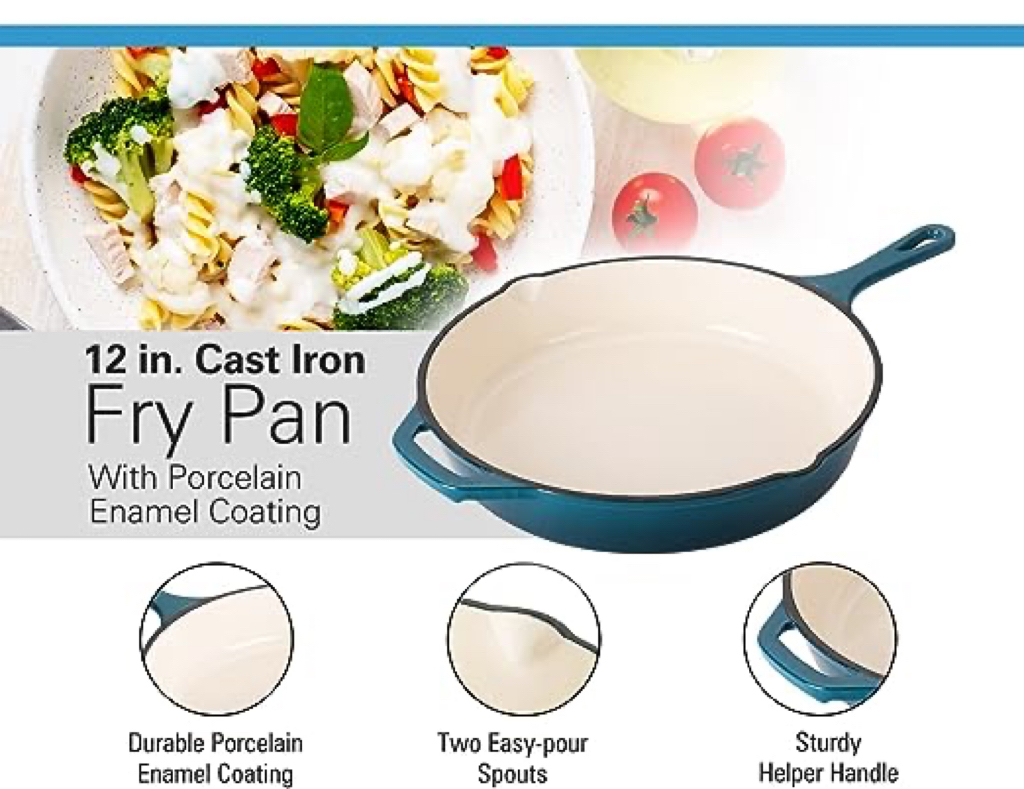

While it is also rare for skillets to come with a lid, you’ll certainly see it more often than you would on a frypan. The lid is also typically fully opaque so you won’t be able to monitor your cooking as easily. But it sure helps with slow-cooking and braising dishes.

Overall, enamel cookware remains a popular choice for home cooks and professional chefs alike. Whether you choose Lightweight Enameled Cast Iron Cookware or Heavy Enamel Cookware, you can be sure that enameled cookware will provide reliable performance and stylish appeal to your kitchen for years to come.

:max_bytes(150000):strip_icc():format(webp)/overhead-of-empty-cast-iron-skillet-on-white-background-72323233-58853f4d3df78c2ccda8d8dc.jpg)

Why chefs prefer stainless steel cookware over aluminium cookware?

One of the most significant features is the flat bottom, which provides consistent heat distribution throughout the cooking process. You don’t want your eggs undercooked in some portions due to an uneven cooking area or a poor heat conductor.

And the risk of zoonotic diseases, transmitted from animals to humans, would be minimized And the risk of zoonotic diseases, transmitted from animals to humans, would be minimized

And the risk of zoonotic diseases, transmitted from animals to humans, would be minimized And the risk of zoonotic diseases, transmitted from animals to humans, would be minimized press for meat.

press for meat.