heavy duty vertical froth pump manufacturers

Latest articles

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read MoreSlurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read MoreIdeal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read MoreIdeal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read MorePositive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read MoreSubmersible Slurry Pump

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read More600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read MoreSlurry pumps can be used for.

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read MoreSelecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

heavy duty vertical froth pump manufacturers...

heavy duty vertical froth pump manufacturers 【heavy duty vertical froth pump manufacturers】

Read More

Popular articles

- To reduce wear, reduce the pump discharge pressure to the lowest possible point.

- Slurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

- - Pumping media where abrasive particles are present

- >Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

- Sump drainage or washdown

- What is a dredging pump?

Latest articles

-

A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

-

of a thick consistency, and.

-

One problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

-

If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

-

Vertical Slurry Pumps Pump Sewage More Efficiently

-

How to Choose a Dredging Pump or Slurry Pump

Links

This commitment not only benefits the environment but also aligns with the increasing demand for eco-friendly products in the global market This commitment not only benefits the environment but also aligns with the increasing demand for eco-friendly products in the global market

This commitment not only benefits the environment but also aligns with the increasing demand for eco-friendly products in the global market This commitment not only benefits the environment but also aligns with the increasing demand for eco-friendly products in the global market pigment titanium dioxide factory.

pigment titanium dioxide factory.Authors like to thank Sebastián García (LAMARX) for spectra acquisition, Carolina Leimbruguer for her support with TEM images and Yanina Altamirano, Nicolas Jaime and Javier Reparaz for animal care assistance.

3. Safety measures The MSDS should provide recommendations for safe handling, storage, and disposal of lithopone. This may include guidelines for personal protective equipment, proper ventilation, and spill response procedures.

wholesale lithopone msds quotes

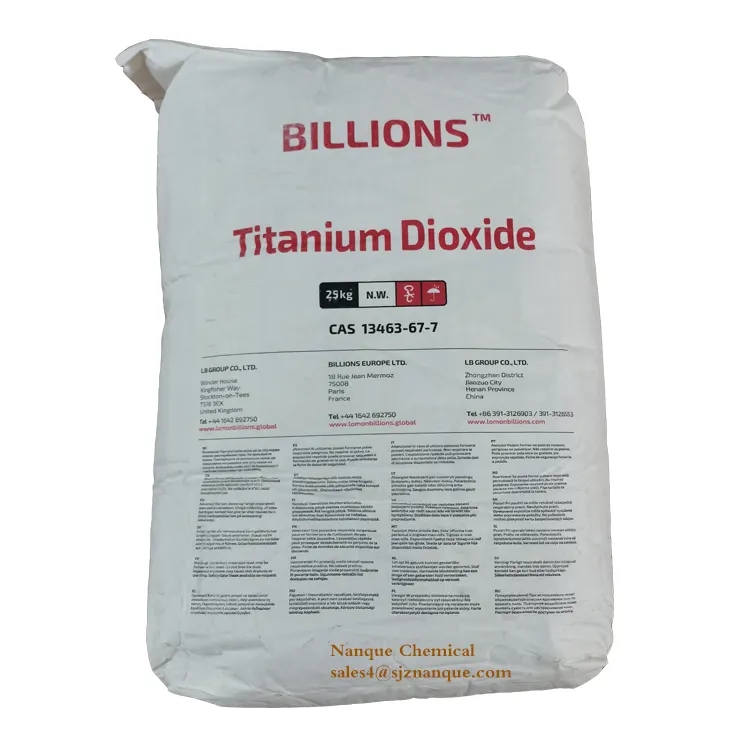

A few processes are used to produce TiO2 pigment. Rutile TiO2 is found in nature. This is because the rutile crystal structure is the thermodynamically stable form of titanium dioxide. In chemical processes natural TiO2 can be purified, thus obtaining synthetic TiO2. The pigment can be made from ores, rich in titanium, that are mined from the earth.

Two chemical routes are used to make both rutile and anatase TiO2 pigments.

What is the FDA limit for titanium dioxide?

Lithopone manufacturer: Application areas

Lithopone has therefore traditionally been used in stoppers and putties, jointing compounds and sealing compounds, primers and undercoats and in road-marking paints.

Currently, titanium dioxide as a food additive is classified as GRAS, or “generally recognized as safe.”

wholesale define titanium dioxide. It is also used in makeup products to create a natural, matte finish. In the food industry, titanium dioxide is used as a colorant to enhance the appearance of foods and beverages.

wholesale define titanium dioxide. It is also used in makeup products to create a natural, matte finish. In the food industry, titanium dioxide is used as a colorant to enhance the appearance of foods and beverages.Hiding power

In their role as risk managers, the European Commission and Member States will now reflect on EFSA’s scientific advice and decide upon any appropriate regulatory measures or advice for consumers.

6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications.

6618 titanium dioxide.2 eV. This property makes it suitable for use in solar cells and other electronic devices. Titanium dioxide can be doped with other elements to improve its electrical conductivity and enhance its performance in these applications.The FDA first approved the use of titanium dioxide in food in 1966, following its 1960 removal (along with the removal of other color additives) from the agency's original Generally Recognized as Safe list. In 1977, titanium dioxide joined the list of color additives that are exempt from certification, which means titanium dioxide doesn't have to be listed on the packaging of every product it's used in, Faber noted.

They have a strong track record of delivering products on time, ensuring that customers receive their orders when they need them They have a strong track record of delivering products on time, ensuring that customers receive their orders when they need them

They have a strong track record of delivering products on time, ensuring that customers receive their orders when they need them They have a strong track record of delivering products on time, ensuring that customers receive their orders when they need them titanium dioxide r-996 manufacturers.

titanium dioxide r-996 manufacturers.

The compound in the Asia Pacific market experienced a mixed trends throughout the fourth quarter of 2021. These market attitudes were mostly related to lower operational loads at Chinese domestic manufacturing plants.