heavy duty slurry pump factory

Latest articles

As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read MoreUnderwater installation

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read MoreHigh head (i.e. the height to which the pump can move the liquid)

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read MoreFor pumping abrasive slurries, these types of pumps can also be made from specialised high-wear alloys. Hardened stainless steel is also a common choice for abrasive slurries.

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read MoreChoosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read MoreIf centrifugal, are the impellers of the right design and material?

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read MoreThe dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

heavy duty slurry pump factory...

heavy duty slurry pump factory 【heavy duty slurry pump factory】

Read More

Popular articles

- Abrasive.

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- Find a professional slurry pump supplier

- Determine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

- WA Heavy-duty Slurry Pump

Latest articles

-

method and level of design reach international advanced level. The company has the first-class pump performance

-

WY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

-

>Slurry Pump

-

Light-duty Slurry Pump

-

In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

-

Slurry Pump

Links

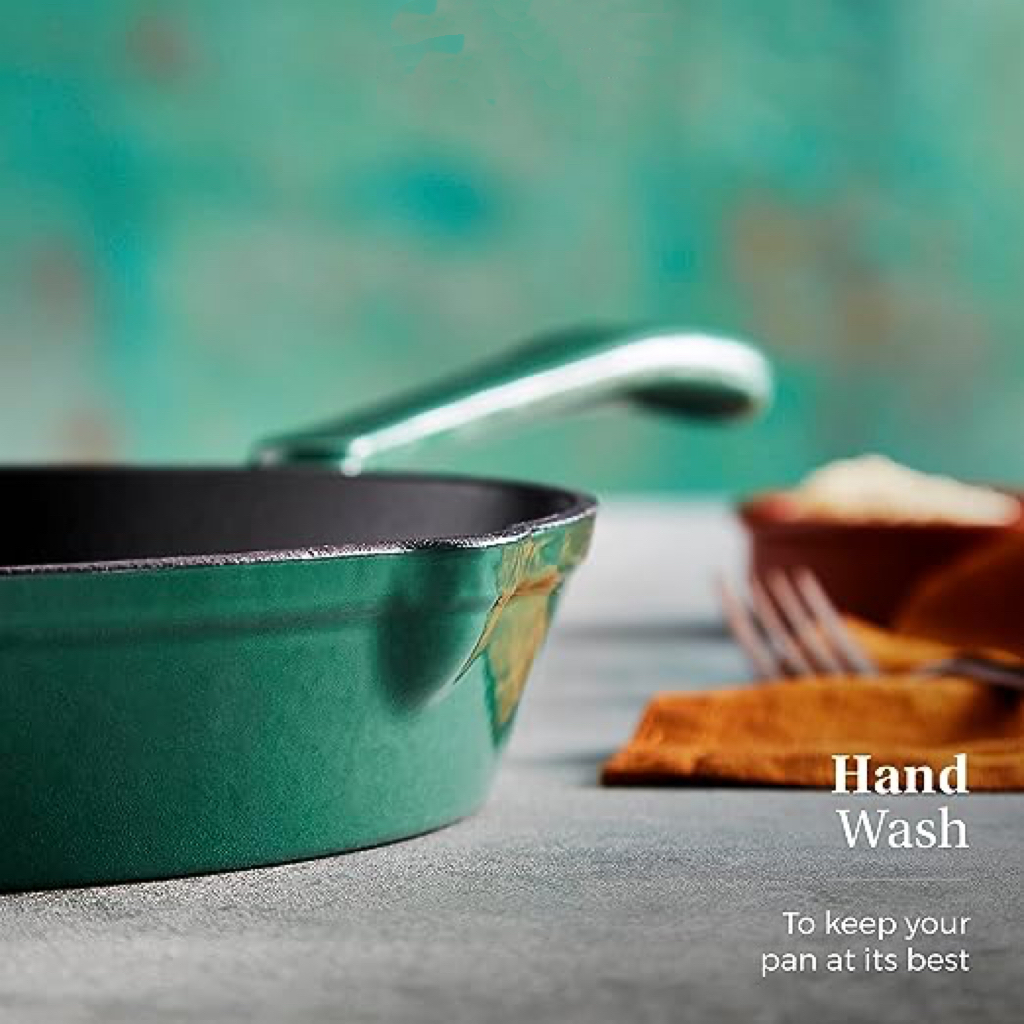

- Ceramic and enameled cast iron cookware have become increasingly popular in recent years, thanks to their durability, versatility, and aesthetic appeal. These types of cookware offer a unique blend of traditional cooking methods with modern conveniences, making them a favorite among home cooks and professional chefs alike.

- In the heart of every kitchen lies a collection of cookware that defines its character. Among these essential tools, the enamel cookware set stands out for its timeless appeal and exceptional performance. This versatile set is not only a joy to use but also a stylish addition to any kitchen decor.

French skillets also come in different sizes, but they are typically much smaller, ranging from 8 to 12 inches.

Uses Of Skillet

Stainless steel

custom cast iron griddle. Unlike non-stick pans that can chip, scratch, and wear out over time, cast iron griddles only improve with age. They can withstand high heat and constant use without warping or deteriorating, making them a reliable and long-lasting kitchen investment.

cast iron round dutch oven. It can go from stovetop to oven without missing a beat, allowing for searing and then slow cooking in one convenient piece of cookware. It's also incredibly energy-efficient, retaining heat so well that once it's hot, it requires less energy to maintain temperature than other types of cookware.

cast iron round dutch oven. It can go from stovetop to oven without missing a beat, allowing for searing and then slow cooking in one convenient piece of cookware. It's also incredibly energy-efficient, retaining heat so well that once it's hot, it requires less energy to maintain temperature than other types of cookware.When looking to buy cast iron cookware, it's essential to consider factors such as the number of pieces included in the set, the type of enamel coating used, and the reputation of the manufacturer. Opting for an enameled cast iron cookware set ensures versatility in the kitchen, allowing for seamless transitions from stovetop to oven to table.

They have a single, long handle, like fry pans, but also usually feature a smaller side handle to help the cook lift the added weight of more food. Saute Pans also usually come with a lid designed to hold in moisture. This makes them much more useful for slow cooking with sauces.

Skillet

Granite or stone frying pans are made from a combination of materials, such as ceramics, stone, and titanium. These pans are known for their durability and non-stick properties. They are ideal for cooking delicate dishes and reducing the amount of oil needed for cooking. However, they are prone to chipping or cracking with rough handling, so it's important to handle them with care.

Granite or stone frying pans are made from a combination of materials, such as ceramics, stone, and titanium. These pans are known for their durability and non-stick properties. They are ideal for cooking delicate dishes and reducing the amount of oil needed for cooking. However, they are prone to chipping or cracking with rough handling, so it's important to handle them with care.

A ceramic frying pan is also non-stick, but, unlike common non-stick pans which are coated with some chemical substance, ceramic pans are coated with a silica gel made from sand or ceramic stone.

Granite or stone frying pans are made from a combination of materials, such as ceramics, stone, and titanium. These pans are known for their durability and non-stick properties. They are ideal for cooking delicate dishes and reducing the amount of oil needed for cooking. However, they are prone to chipping or cracking with rough handling, so it's important to handle them with care.

Granite or stone frying pans are made from a combination of materials, such as ceramics, stone, and titanium. These pans are known for their durability and non-stick properties. They are ideal for cooking delicate dishes and reducing the amount of oil needed for cooking. However, they are prone to chipping or cracking with rough handling, so it's important to handle them with care.

While the drawbacks of using carbon steel cookware are few and far between, they do come with a slightly more complicated user manual than non stick or stainless steel pans.