high quality ash slurry submersible pump suppliers

Latest articles

What is the optimum seal arrangement for the application?

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read MoreFollow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read MoreSelecting a dredge pump

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read MoreCritical to the engineering of the pump are heavy duty bearing frames and shafts, extra thick wall sections and easily replaceable wear parts. Total life cycle cost considerations are critical when specifying pumps for severe operating conditions, such as FGD service. High chrome pumps are ideal due to the corrosive pH of the slurry.

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read More3. Both pumps and motors are designed separately.

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read MoreSlurry Pump Speed

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read MoreSlurry Pump

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read MoreSlurry pump vs mud pump

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read MoreThe size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

high quality ash slurry submersible pump suppliers...

high quality ash slurry submersible pump suppliers 【high quality ash slurry submersible pump suppliers】

Read More

Popular articles

- If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

- The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

- Depending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

- Slurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

- The rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

Latest articles

-

Choosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

-

If you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

-

Ideal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

-

Many types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

-

- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

-

In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

Another significant benefit of butyl rubber tape is its exceptional sealing properties. It is often used as a waterproofing solution, capable of sealing joints, gaps, and cracks to prevent water intrusion. This feature is particularly valuable in roofing applications, where leaks can lead to extensive damage and costly repairs. Butyl rubber tape can also be used in plumbing to seal pipes and fixtures effectively.

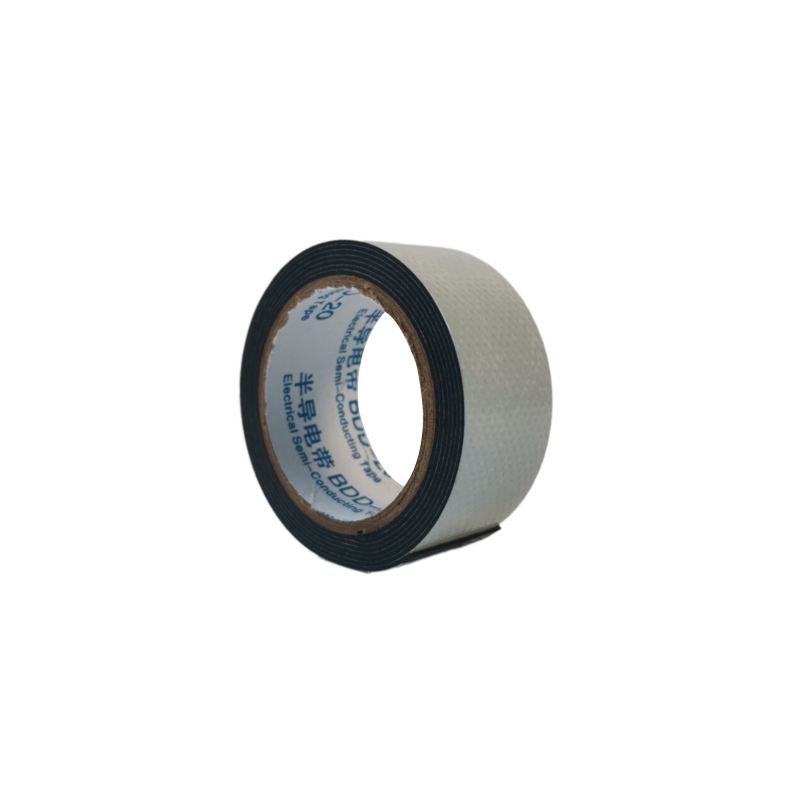

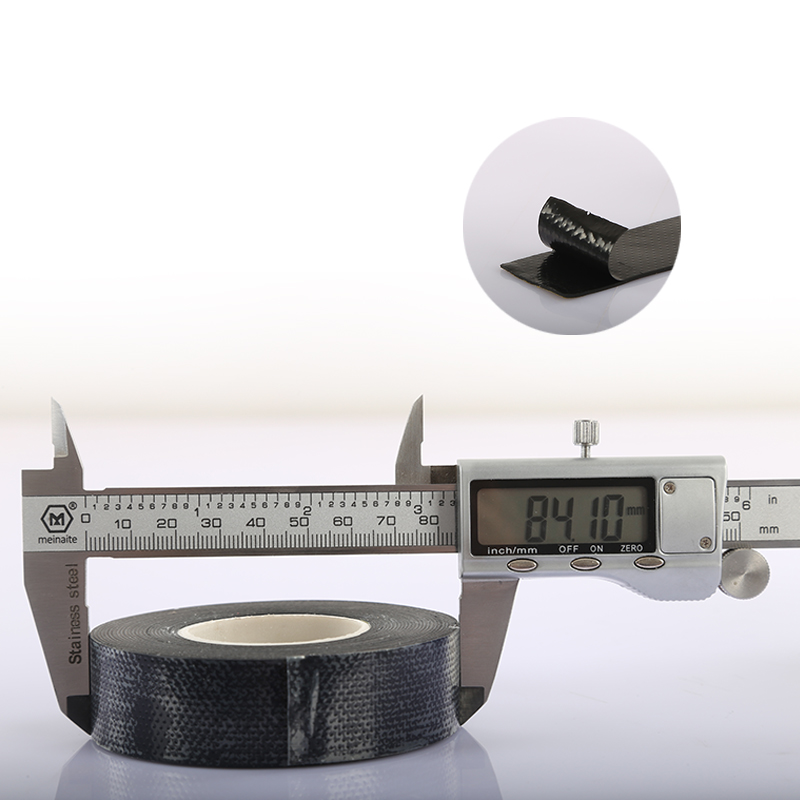

The Different Types of Electrical Insulation Tape and Their Uses

NON-TOXIC RUBBER TAPE (NORMAL STORAGE) AND TECHNICAL DATA

Another important feature of Flex Tape 4 is its strength. The tape is rated to hold up to 50 pounds of weight per square inch, making it suitable for a wide range of applications. Whether you need to repair a leaky pipe, patch up a hole in your roof, or fix a broken garden hose, Flex Tape 4 is up to the task.

flex tape 4

One of the significant advantages of using fireproof gasket tape is its versatility. It can be employed in various applications, including but not limited to sealing joints in HVAC systems, creating airtight seals in exhaust systems, and providing insulation in electrical enclosures. The tape can also be used in industries dealing with flammable materials, where it plays a crucial role in enhancing the safety of the work environment.

waterproof butyl rubber aluminium foil tape. Additionally, it can be used for automotive repairs, insulation, and even crafting projects.

Its flexibility allows it to conform to complex shapes, while its non-slip nature ensures a secure hold Its flexibility allows it to conform to complex shapes, while its non-slip nature ensures a secure hold

Its flexibility allows it to conform to complex shapes, while its non-slip nature ensures a secure hold Its flexibility allows it to conform to complex shapes, while its non-slip nature ensures a secure hold pvc tape black.

pvc tape black.

high speed splicing tape. Its strong adhesive properties ensure that spliced materials stay securely bonded together, even under extreme stress or tension. This makes high-speed splicing tape an ideal solution for industries that require reliable and long-lasting splices, such as the packaging and printing industries.

Wire Sizing and Component Types

Its bright color and sleek design make it a stylish addition to any toolbox or workspace Its bright color and sleek design make it a stylish addition to any toolbox or workspace

Its bright color and sleek design make it a stylish addition to any toolbox or workspace Its bright color and sleek design make it a stylish addition to any toolbox or workspace pink electrical tape. This can be particularly useful for professionals who want to add a touch of personality to their work environment.

pink electrical tape. This can be particularly useful for professionals who want to add a touch of personality to their work environment.Self-adhesive insulation tape is typically made from a combination of high-quality materials, including PVC, rubber, or cloth. Its inherent characteristics allow it to adhere firmly to a wide range of surfaces while providing robust insulation properties. The tape is designed to resist tearing, stretching, and weathering, making it suitable for indoor and outdoor use. Many brands offer tape that is also resistant to moisture, chemicals, and extreme temperatures, enhancing its durability and effectiveness.

In the realm of adhesive materials, PVC black tape stands out for its exceptional versatility and reliability. This specialized tape, made from polyvinyl chloride (PVC), is predominantly black in color, making it an aesthetically pleasing option for various applications. It is a staple in many industries, including electrical, construction, automotive, and arts and crafts, due to its unique properties and benefits.

Overall, PVC electrical insulation offers a versatile and reliable solution for a wide range of applications. Its high dielectric strength, flexibility, durability, and cost-effectiveness make it a popular choice for electrical wiring, cabling, and other applications. Whether used indoors or outdoors, PVC insulation provides a safe and effective solution for insulating electrical conductors and preventing electrical leakage. With its many benefits, it's no wonder that PVC electrical insulation is a go-to choice for many industries.

It’s common for well control box installers to carry multi-purpose control boxes with them so they can install one at any job site. This sometimes results in the consumer paying more for something they don’t need.