small gold dredge pump manufacturer

Latest articles

Some models can generate discharge pressures up to 260 ft. (80 m).

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read MoreTL FGD Pump

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read MoreHigh head (i.e. the height to which the pump can move the liquid)

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read MoreConveying medium

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read MoreCapacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read MoreDetermine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read Moreof a thick consistency, and.

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read MoreIf you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read MoreHow to Choose a Dredging Pump or Slurry Pump

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read MoreSelecting a dredge pump

small gold dredge pump manufacturer...

small gold dredge pump manufacturer 【small gold dredge pump manufacturer】

Read More

Popular articles

- Slurry Pump

- of a thick consistency, and.

- Consideration should be given to installing mixers on guide rods in the catch basin/tank to keep solids in suspension and avoid settling in the catch basin/tank. When investing in a slurry pump, you want to pump slurry that includes solids, not just dirty water. Therefore, it is important to make sure that the pump is doing this; by using an agitator, the pump is fed with solids and pumping the slurry.

- What is the optimum seal arrangement for the application?

- Slurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

- If youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

Latest articles

-

Slurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

-

The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

-

A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

-

How does a dredge pump work?

-

WA Heavy-duty Slurry Pump

-

A , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

Links

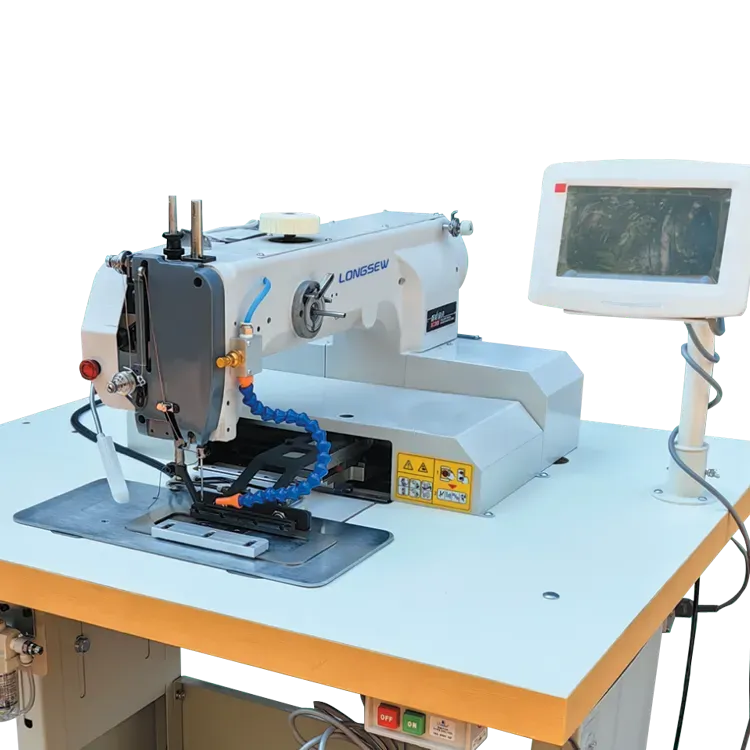

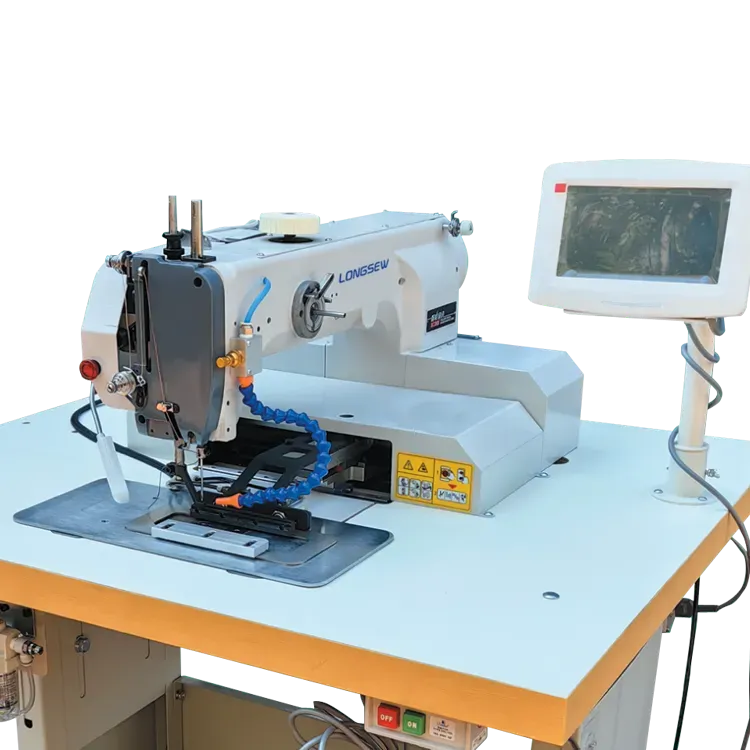

Maintenance of an automatic buttonhole sewing machine is also relatively straightforward. Regular cleaning and oiling are essential to keep the machine running smoothly, but many models are designed for longevity and ease of repair. Furthermore, with the advancement of online tutorials and communities, users can easily find help and resources to troubleshoot any issues that may arise.

Choosing the Right Heavy-Duty Quilting Sewing Machine

1. Elasticity One of the most defining features of the overlock chain stitch is its inherent stretch. This is particularly beneficial when working with fabrics that are prone to stretching, such as jersey or spandex. The stitch can accommodate the movement of the garment without breaking or causing stress on the seams.

single needle sewing machine price

5. Market Demand The general economy and industry-specific demands can also impact pricing. High demand for bag closing machinery, especially during peak production seasons, can drive up prices. Conversely, during slower economic periods, discounts and deals may be more common as suppliers aim to maintain sales volumes.

They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads

They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads