china underwater dredge pump

Latest articles

Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read MoreBetter safety

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read MoreTo reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read MoreAIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read MoreDredge Pump

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read MoreLarger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read MoreSelecting a dredge pump

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read MoreCorrosiveness of the slurry

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read MoreExpertise and experience

china underwater dredge pump...

china underwater dredge pump 【china underwater dredge pump】

Read More

Popular articles

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

- In harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

- Slurry Pump

- Is the discharge configuration suitable for abrasive slurries?

- Step 2

- All products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

Latest articles

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

-

The length of the piping. The longer the pipe, the more slurry-induced friction the pump needs to overcome.

-

Find a professional slurry pump supplier

-

Slurry pump seals

-

Slurry Pump selection

-

In AIER® slurry pumps, WY & WYJ sump pump are vertical centrifugal slurry pump, submerged for transfer abrasive, coarse particles and high density slurry. When working, it needs no seal water or any kind of seal. It can work well as well when suction volume is not enough.

Links

- As the days turned into weeks and months, the once vibrant red hue of the tape began to fade. Its edges frayed from the endless trampling of heavy boots and wheels of machinery rolling over it. Yet, even in its worn state, the red floor tape held its purpose steadfastly, continuing to divide and conquer the chaos of the work environment.

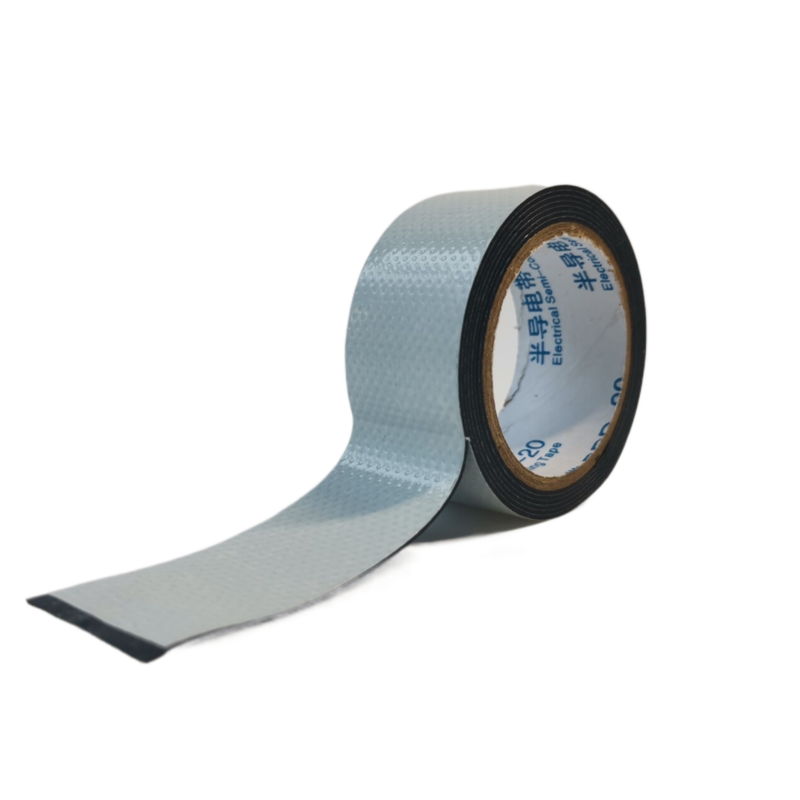

TAPES & SEALANTS

Our self-amalgamating tape is RoHS compliant, to give you the peace of mind that it contains none of the restrictive materials banned under the Restriction of Hazardous Restrictions (RoHS) and offers REACH compliance. This demonstrates that the European Chemicals Agency (ECHA) has passed it safe for use without harm to the end user. Available in two popular widths and three lengths, this forms part of our extensive range of tapes that we always have in stock.

Choosing the right butyl rubber tape supplier is essential for ensuring the success of your project. A reliable supplier not only provides high-quality products but also offers technical support and customization options. By considering the factors outlined above—reputation, product quality, customization capability, pricing, and sustainability—you can make an informed decision that meets the demands of your specific application. Investing time in selecting the right supplier will pay off in the long run, resulting in better project outcomes and customer satisfaction.

black tack butyl. It comes in a convenient tube that allows you to apply the adhesive directly to the surface you want to bond. The tube is designed with a nozzle that allows you to control the flow of the adhesive, ensuring that you get just the right amount for your project.

black tack butyl. It comes in a convenient tube that allows you to apply the adhesive directly to the surface you want to bond. The tube is designed with a nozzle that allows you to control the flow of the adhesive, ensuring that you get just the right amount for your project.

Bundling and Organization

Overall, Flex Tape is a versatile and reliable product that can be a handy addition to any DIY toolkit. Whether you need to temporarily fix a leak, repair a broken object, or secure a heavy item in place, Flex Tape can get the job done quickly and effectively. Just remember to follow the instructions carefully and use it in the appropriate situations to ensure the best results.

Flex Tape 4 is also easy to use. Simply cut the desired length of tape, peel off the backing, and apply it to the surface that needs repairing. The tape will bond instantly, creating a strong and durable seal that will hold up over time. No additional tools or materials are required, making Flex Tape 4 a convenient and cost-effective solution for DIY projects.

Also referred to as self-fusing tape, self-amalgamating tape is a non-sticky tape that will only adhere to itself. To amalgamate means “to mix or merge so as to make a combination; blend; unite; combine.” So, when one layer of tape is stretched and placed over another layer of self-amalgamating tape, the two layers ‘blend’ or ‘combine’ to become a solid piece.

Selecting the right tape for your repair project depends on various factors. To make an informed choice, consider the following:

Butyl rubber is known for its exceptional impermeability to air, water, and other gasses, as well as its resistance to heat, chemicals, and UV radiation.

What is Heat Tape?