high quality submersible pump vertical

Latest articles

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read MoreWhen pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read MoreLarger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read MoreThe FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read MoreIf you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read More- Pumping the final product in a process

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read MoreLow slurry flow rates

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read More>Dredge Pump

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read MoreA slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

high quality submersible pump vertical...

high quality submersible pump vertical 【high quality submersible pump vertical】

Read More

Popular articles

- Determine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

- Low slurry flow rates

- Auxiliary equipment

- In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

- Dredge Pump

- With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

Latest articles

-

Slurry pump construction materials

-

- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

-

Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

-

Slurry Pump Considerations

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

Links

- Blue enamel cooking pots, with their timeless elegance and functional resilience, have been a staple in kitchens for generations. These beautiful cookware pieces not only add a dash of color to culinary spaces but also offer a blend of style and substance that is hard to resist.

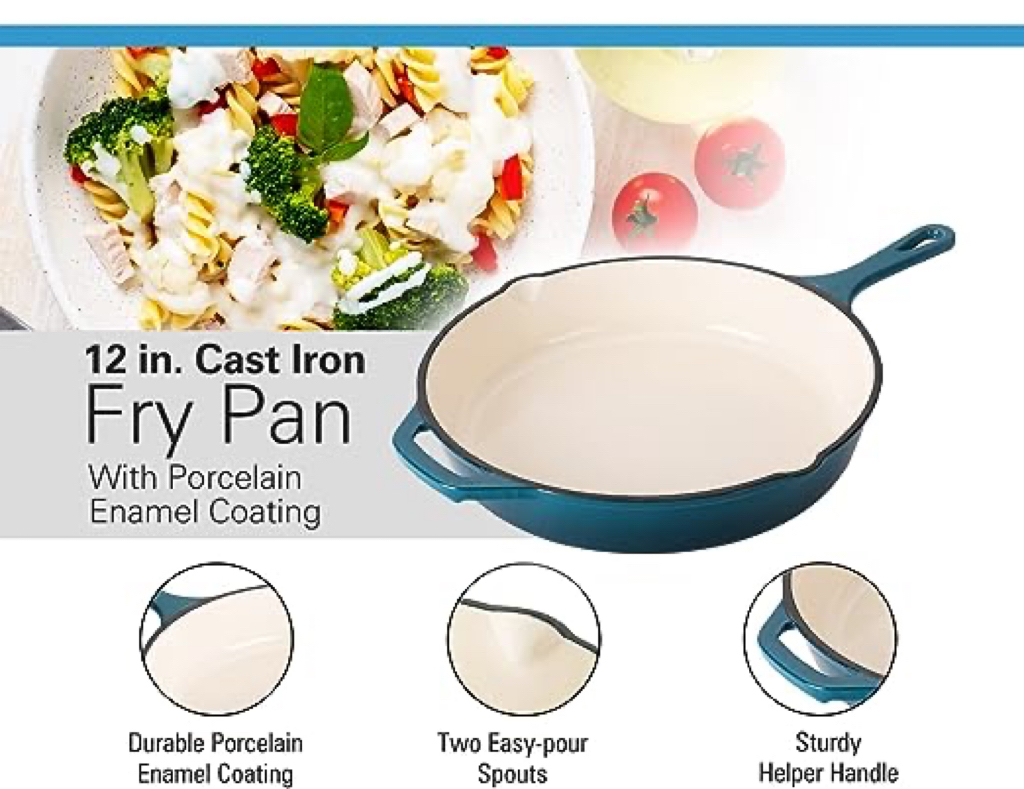

- Crafted from a thick slab of iron, the large surface area of a cast iron skillet ensures even heat distribution. This feature makes it perfect for cooking meals that require consistent temperatures, such as a hearty vegetable stir-fry or a piping hot pizza. The weightiness of the skillet also means it can handle high heat without warping, unlike lighter pans that might distort under the intensity of a blazing flame.

- Cleaning a cast iron camping griddle is relatively straightforward. While it requires a bit more attention than modern non-stick pans, the effort is worth it for the longevity and health benefits. Avoid using soap, instead, scrub it with water and a stiff brush, then dry it thoroughly and rub with oil to prevent rusting.

The sloped and rounded sides are slightly higher than a frying pan, resulting in two to three inches of steepness. The high edges prevent the oil and other liquids inside from spilling out.

3. Non-Stick Frying Pans

Considerations:

- One of the most significant advantages of this type of griddle is its reversible nature. With just one flip of the surface, you can switch from grill to griddle and vice versa. This makes it incredibly easy to go from cooking up a batch of pancakes in the morning to grilling vegetables in the evening without having to switch out different pans or clean up excess mess.

- Cleaning a cast iron flat top grill is relatively straightforward. A stiff brush and hot water usually suffice, with occasional use of mild soap if needed. After cleaning, it's essential to dry the grill thoroughly and re-season it to prevent rusting and maintain its non-stick properties.

Cleaning Cast Iron Camp Oven

Fry pans come in a greater variety of sizes, making it easy to adjust to the food being cooked, whereas French skillets are designed to handle larger quantities of food.

Sizzling Plates for Sale:

Using A Cast Iron Griddle On An Electric Stove

Kitchen Cookware Multifunction Rectangular Frying Pan Cast lron Wok

The skillet becomes a canvas on which these ingredients paint a masterpiece of colors and flavors The skillet becomes a canvas on which these ingredients paint a masterpiece of colors and flavors

The skillet becomes a canvas on which these ingredients paint a masterpiece of colors and flavors The skillet becomes a canvas on which these ingredients paint a masterpiece of colors and flavors skillet cooking.

skillet cooking.