twin casing slurry pump factory

Latest articles

testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read MoreThe length of the piping. The longer the pipe, the more slurry-induced friction the pump needs to overcome.

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read Moreof a thick consistency, and.

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read MoreSlurry Pump Selection

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read MoreIn a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read MoreConsider the following.

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read MoreThere are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read MoreMany types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read MoreSlurry Pump Speed

twin casing slurry pump factory...

twin casing slurry pump factory 【twin casing slurry pump factory】

Read More

Popular articles

- Ideal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

- Slurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

- Non-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

- There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

- Slurry Pump

- Slurry Pump

Latest articles

A commercial zig zag sewing machine is designed to produce a variety of stitch types, particularly the zig zag stitch, which is a fundamental technique in sewing. The zig zag stitch allows for several applications, including finishing raw edges, creating decorative patterns, and applying elastic. Unlike standard sewing machines, which may be limited to straight stitches, commercial zig zag machines typically feature more advanced options, making them suitable for both heavy fabrics and delicate materials.

Gunny bag sewing machines are specialized sewing machines designed to handle the unique requirements of sewing jute and similar heavy materials. These machines are equipped with powerful motors and heavy-duty needles that can penetrate thick fabric, ensuring secure and lasting seams. Unlike regular sewing machines, gunny bag sewing machines are tailored to handle the bulk and weight of gunny bags, making them indispensable in manufacturing operations.

Choosing a long arm heavy duty zigzag sewing machine is an investment in creativity, efficiency, and enjoyment. With its powerful performance, ample workspace, and versatile stitching options, this machine provides the tools needed to tackle a diverse range of sewing projects. Whether you're sewing for fun or crafting items for sale, the long arm heavy duty zigzag sewing machine promises to elevate your sewing experience and bring your visions to life. So why wait? Dive into the world of sewing with a reliable companion that can handle everything you throw at it!

The invention of the PP bag stitching machine, specifically, provided manufacturers with a fast and efficient way to produce and close bags. These machines evolved from simple stitching devices to sophisticated models equipped with features such as adjustable stitching lengths, automatic tension control, and high-speed operations. Modern machines offer increased efficiency, with some able to stitch thousands of bags per hour, thereby significantly enhancing productivity.

5. Motor Power High-speed stitching may not always be ideal for heavy materials. A sewing machine with a strong motor can handle the thickness of fur and leather effectively, ensuring that you can sew at a comfortable pace without overworking the machine.

The Versatility of Zig Zag Embroidery Machines

The hand crank sewing machine for leather exemplifies a blend of tradition and functionality. It invites crafters to slow down, appreciate the craftsmanship, and engage more intimately with their work. As modern technology continues to advance, the timeless appeal of hand crank machines endures, reaffirming their place in the hearts of leather artisans everywhere. Whether you are a seasoned leatherworker or just starting, mastering this classic tool can enrich your creative journey and yield results that reflect both skill and passion.

In summary, extra heavy duty sewing machines play an indispensable role in modern industry. They not only improve product quality and durability, but also boost technological progress and production efficiency across related sectors. Whether in manufacturing daily items or developing high-tech products, heavy duty sewing machines demonstrate exceptional performance as an essential industrial wonder.

1. Increased Efficiency The capability to create two lines of stitching in one pass significantly boosts production speed. This efficiency is especially beneficial in high-volume manufacturing environments, where time is a critical factor.

double stitch machine

4. Material Usage Waste generated during the overlocking process must also be factored into the overall cost. Efficient use of materials can help in minimizing waste and lowering costs.

overlock machine rate

Applications of Lock Stitch Machines

what is a lock stitch machine. Some machines are designed for basic stitching tasks, while others are equipped with multiple needles and feed mechanisms for more complex projects. Industrial lockstitch machines are used in factories and production facilities to sew large quantities of garments and textiles quickly and efficiently.

what is a lock stitch machine. Some machines are designed for basic stitching tasks, while others are equipped with multiple needles and feed mechanisms for more complex projects. Industrial lockstitch machines are used in factories and production facilities to sew large quantities of garments and textiles quickly and efficiently.Handheld machines often come with accessories like extra needles, bobbins, and threaders. These are convenient for quick repairs and small sewing tasks.

*Pro tip: invest in the highest quality needles whenever possible; having a needle break during a project can cost you considerably in material costs and labor hours.

Key Features of Commercial Zig Zag Sewing Machines

The Essential Guide to Heavy-Duty Quilting Sewing Machines

Moreover, sturdy sewing machines are generally designed with user comfort in mind. Many models incorporate ergonomic features such as adjustable speed controls, easy-to-use manual dials, and spacious work areas. This focus on comfort allows sewists to work for extended periods without discomfort, ensuring that creativity flows unhindered. Additionally, many sturdy machines offer a wide selection of presser feet, enabling users to execute various techniques, from quilting to embroidery, with utmost precision.

The Walking Foot

- Needle Positioning The ability to adjust needle positions can enhance the functionality and the types of projects that can be undertaken. Some machines offer various needle spacing options to accommodate different styles of sewing.

Ease of Use:

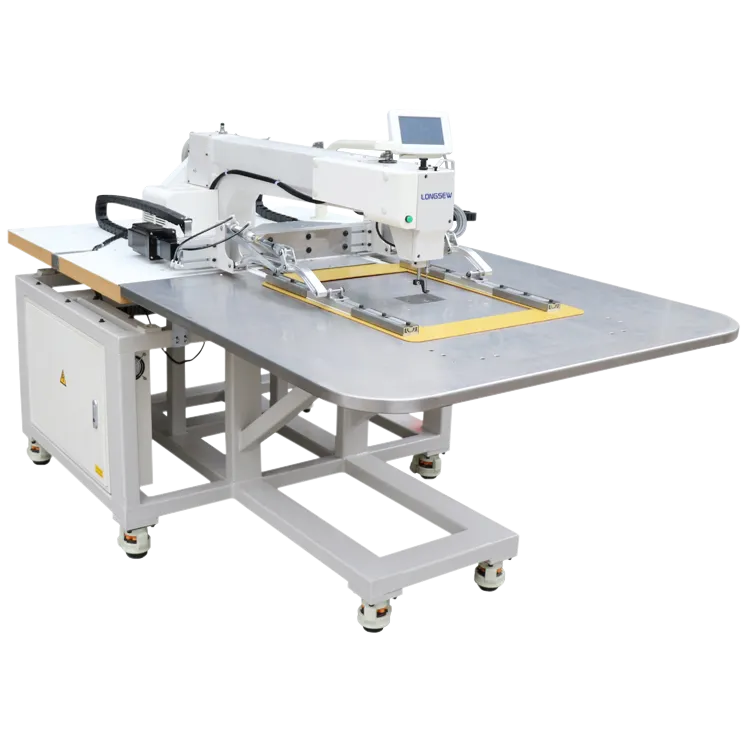

One of the key advantages of automatic template sewing machines is their ability to handle complex patterns that would be exceedingly time-consuming and difficult to replicate by hand. For example, garments featuring elaborate embroidery or detailed appliqué can now be produced swiftly and efficiently. This not only saves time but also reduces labor costs, making it an attractive option for manufacturers looking to maximize their resources.

2. Adjust Tension Settings If you are experiencing uneven stitching, adjust the machine's tension settings. Vinyl can be finicky, and achieving the right tension is crucial for a smooth finish.

The Modern Chain Stitch Machine Revolutionizing Textile Production

Fortunately, many manufacturers provide comprehensive manuals and online resources to assist users in becoming proficient. Engaging in online forums or communities can also offer valuable insights and tips from experienced stitchers.

Modern industrial leather sewing machines are equipped with specialized features such as walking feet, which help move the thick material smoothly through the machine. They also typically possess a powerful motor capable of stitching through multiple layers of leather without skipping stitches. This evolution has made it possible for manufacturers to produce leather goods more efficiently while maintaining high standards of quality.

1. Walking Foot Mechanism A walking foot or compound feed mechanism is essential as it helps move layers of leather through the machine evenly. This feature is particularly useful for sewing thicker materials, preventing the layers from shifting out of place.

industrial leather sewing machine for sale

3. Versatile Stitching Options While the basic chain stitch is common for woven bags, some machines offer multiple stitching patterns, including zigzag and overlock stitches, to accommodate various packaging needs.