china vertical slurry pump suppliers

Latest articles

When pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read MoreWhen slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read MoreWhen flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read MoreCentrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read MoreThe rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read MoreThe mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read MoreMany types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read MoreReduced inventory

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read MoreAs wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

china vertical slurry pump suppliers...

china vertical slurry pump suppliers 【china vertical slurry pump suppliers】

Read More

Popular articles

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

- - Keeping clean catch basins clean from solids

- A slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

- A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

- Slurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

Latest articles

-

The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

-

Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

-

In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

-

Because of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

-

Slurry Pump

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

Links

Heavy duty sewing machines are designed to handle thick fabrics and multiple layers, making them indispensable in industries that require robust stitching capabilities, such as upholstery, leatherworking, and manufacturing of workwear. These machines are built with superior materials and components, ensuring they can withstand the rigors of daily use. However, what truly sets them apart is the motor powering them.

(4) Remove the dust on the machine and lubricate it all, and it is required not less than twice per work shift.

Features of the Dressmaker Zig Zag Sewing Machine

- One of the main advantages of chain stitch sewing is its flexibility. The loops within the stitch allow for more stretch and movement in the fabric, making it ideal for use in garments that need to move with the body, such as activewear and dance costumes. Additionally, chain stitch sewing creates a beautiful decorative effect that can add a unique touch to any project.

3. Customization CNC sewing technology allows for easy customization of designs. Whether it’s for a small batch of unique clothing items or large-scale production runs, CNC machines can quickly adapt to various designs without the need for extensive retooling. This capability is especially beneficial for businesses that prioritize individualized products.

- Needle Compatibility Ensure that the machine can accommodate various needle sizes that are suitable for leather work. Larger needles are typically required for thicker leather.

The hand-powered leather sewing machine is more than just a tool; it symbolizes a return to craftsmanship and traditional skills in a fast-paced world. With its ability to create high-quality, bespoke items, this machine continues to be an invaluable asset for leatherworkers. As artisans embrace the beauty of handmade products, the hand-powered leather sewing machine endures as a testament to the artistry and dedication that define the craft of leatherworking. Whether you are a seasoned artisan or a hobbyist, exploring the world of hand-powered sewing machines can elevate your leatherwork experience and enhance your creativity.

3. Versatility Modern industrial overlockers come with a variety of features such as different stitch types, differential feed mechanisms, and adjustable presser feet. This versatility allows manufacturers to handle a range of fabrics, from lightweight knits to heavier materials.

2. Thread Opt for strong, heavy-duty thread like polyester or nylon. These threads are less likely to break under strain and will hold up against the robust fabric.

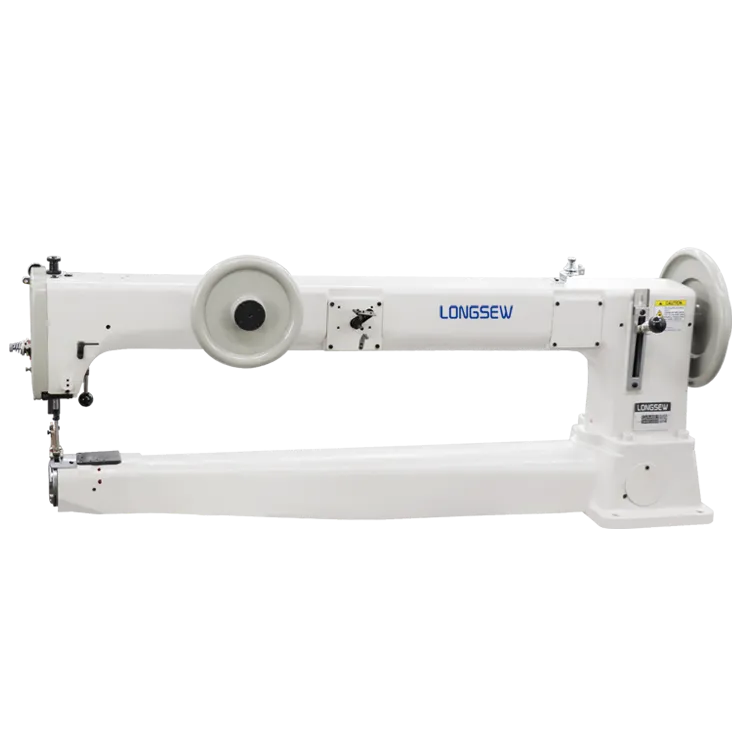

An industrial long arm sewing machine is designed for heavy-duty sewing applications, offering an extended arm length that allows for greater flexibility and space when working with larger pieces of fabric. These machines are ideal for quilting, upholstery, and any project that involves handling sizable materials, such as curtains, blankets, and other bulky items.

cub leather sewing machine. With its easy-to-use controls and clear instructions, you will be able to start sewing with confidence right away. Whether you are a seasoned leatherworker or just starting out, the Cub Leather Sewing Machine is perfect for crafters of all skill levels.

Understanding Upholstery Hand Sewing Machines

The double needle sewing machine has widespread applications in the garment industry, particularly in the production of knitwear, activewear, and denim. It is also favored in quilting and home sewing projects where aesthetic appeal is paramount. The machine’s ability to create decorative stitching makes it a popular choice for embellishments, adding personal touches to various fabric items.

Before starting on your main project, it’s recommended to practice on scrap fabric to perfect your tension settings and stitching technique. This will not only build your confidence but also allow you to make any necessary adjustments to avoid mishaps in your final product.

Moreover, automatic machine sewing allows for greater design complexity. With the incorporation of computerized technology, designers can create intricate patterns and unique styles that were previously challenging to achieve with manual sewing. These machines can execute elaborate designs with precision, allowing for a wide range of creative possibilities. As a result, fashion brands can experiment with diverse fabrics, textures, and designs, pushing the boundaries of traditional garment construction.

automatic machine sewing

Conclusion

leather machine needle. The size of the needle can affect the overall appearance and durability of your stitches. A smaller needle may create finer and more precise stitches, while a larger needle can be used for thicker and heavier leather.

D. Outdoor Gear and Bags:

Readers will find inspiration for sewing outdoor gear like backpacks, tents, and camping accessories that require the durability and strength provided by heavy duty machines.

The overlock machine, often referred to as a serger, is another crucial piece of equipment in any sewing studio. Its primary function is to trim and finish fabric edges simultaneously, preventing fraying and ensuring that garments last longer. Overlock machines use multiple threads, typically between three and five, to create a secure seam that stretches along with the fabric, much like what a coverstitch machine does but on a different scale.

coverstitch overlock machine

Heavy Duty Home Sewing Machines The Ultimate Tool for Every Sewing Enthusiast

Moreover, the machine’s design encourages easy maintenance and repair, which is vital for continuous operation in busy factories. The simplicity of its components allows for quick troubleshooting and replacement, minimizing downtime. As businesses seek to optimize their production lines, the reliability of the modern chain stitch machine plays a crucial role in sustaining operations and maximizing output.

There are several types of bag closing machines available, each designed to meet specific operational requirements

. The most common types include sewing machines, heat sealing machines, and ultrasonic closing machines.3. Improved Control With greater visibility and accessibility, sewists experience better control over their projects. The ability to see and manage fabric movements effectively contributes to precision and reduces the likelihood of errors.

The advantages of using high-speed single needle lockstitch sewing machines are numerous. First and foremost is their ability to enhance production efficiency without compromising on quality. The uniform stitch quality helps in reducing fabric waste and minimizes the need for rework, which can be a significant cost saver for manufacturers.

Another noteworthy application of the zigzag foot is its proficiency in finishing edges—an essential technique that helps prevent fraying. The smooth, continuous motion of the zigzag around the fabric perimeter helps secure the edges and provides a polished look to garments and accessories. This multifunctionality simplifies the sewing process, enabling makers to focus more on design and creativity rather than on tedious finishing techniques.

3. SINGER Heavy Duty 4423 This budget-friendly option doesn’t compromise on quality. With a strong motor, a variety of stitch options, and a stainless steel bedplate, the SINGER Heavy Duty 4423 is perfect for beginners who want to sew leather and vinyl without breaking the bank.

In summary, upholstery hand sewing machines are essential tools that bridge the gap between tradition and contemporary design. They offer unmatched precision and versatility that allow artisans to create beautiful, functional pieces of furniture. By preserving the techniques of hand sewing, these machines not only keep the art of upholstery alive but also celebrate the richness of craftsmanship in an increasingly automated world. An upholstery hand sewing machine is not just a tool; it is a symbol of dedication, creativity, and the enduring spirit of handcrafted artistry.

Handheld sewing machines typically offer basic straight stitch functionality. They lack the versatility of full-sized sewing machines, which can provide various stitch patterns and options. This limitation can be restrictive if you have more complex sewing projects in mind.