Insulating Motor Connections For Reliability

high speed splicing tape. Its strong adhesive properties ensure that spliced materials stay securely bonded together, even under extreme stress or tension. This makes high-speed splicing tape an ideal solution for industries that require reliable and long-lasting splices, such as the packaging and printing industries.

One of the primary uses of temporary floor marking tape is to enhance safety. In industrial settings, for instance, color-coded tape can indicate pedestrian walkways, machinery zones, and emergency exits. By clearly marking these areas, businesses can significantly reduce the risk of accidents. Visual cues help employees understand where they can walk and where they should be cautious, promoting a safer work environment.

The advantages of using red and white floor marking tape extend beyond simple aesthetics. Here are some key benefits

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions.

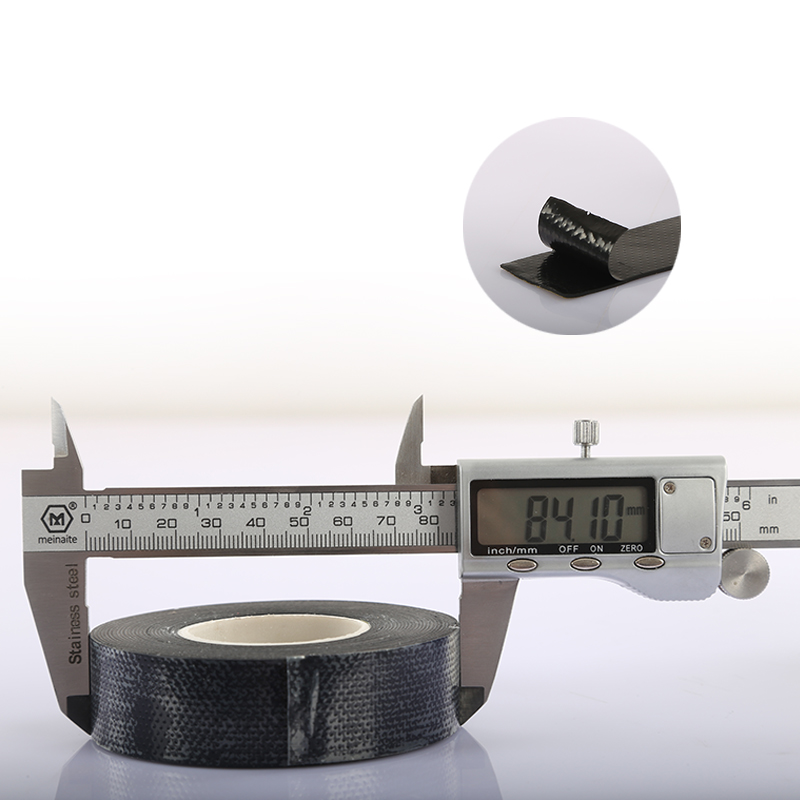

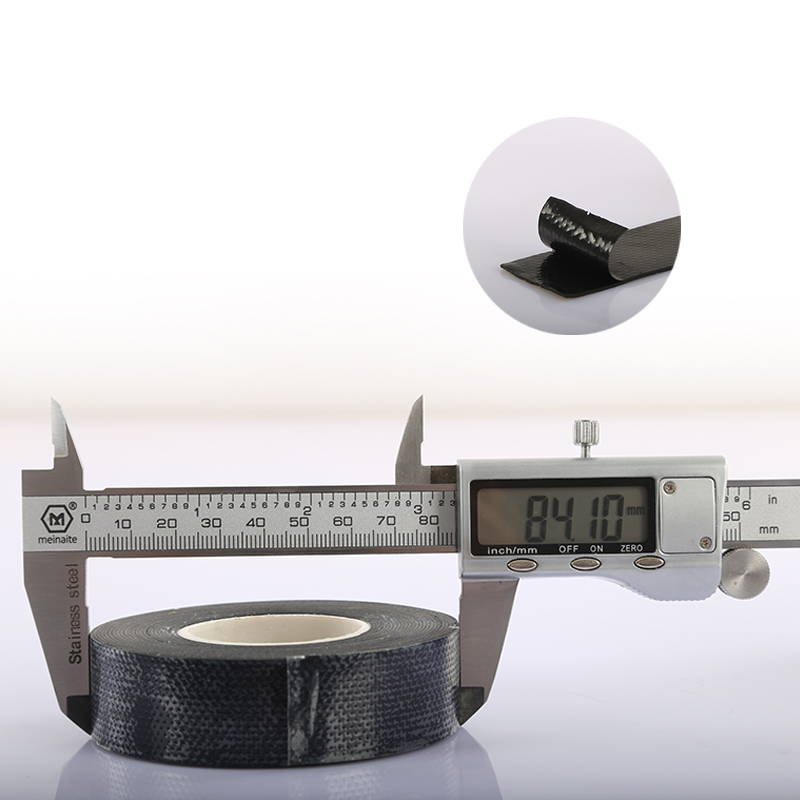

self amalgamating electrical tape. It can withstand temperatures ranging from -65°F to 220°F, making it ideal for use in harsh environments. Its waterproof properties also make it a great choice for outdoor electrical repairs, as it can protect against rain and other weather conditions. 50mm insulation tape. This color-coding system aids in identification, organization, and adherence to safety protocols, making it easier for electricians and technicians to work efficiently.

50mm insulation tape. This color-coding system aids in identification, organization, and adherence to safety protocols, making it easier for electricians and technicians to work efficiently.Corrosion resistance – the dielectric strength of electrical tape is a measure of its electrical strength as an insulator. Vinyl electrical tape is available with differing dielectric strength making it ideal to use for insulating high-voltage wires over extended periods of time. By comparison, PVC electrical tape can be used in similar situations but care should be taken that its dielectric strength is sufficient to insulate active wires.

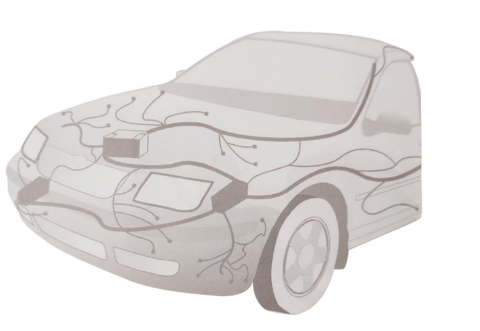

They also come with elaborate circuits and wiring, which links accompanying components as well as your linked devices. Most of the wiring links your sensors, power supply, actuators, and transformers. Circuit boards, on the other hand, organize the wiring and electrical connections in your control box.

Moreover, it finds application in the automotive industry for sealing car trunks, windows, and other areas prone to water intrusion Moreover, it finds application in the automotive industry for sealing car trunks, windows, and other areas prone to water intrusion

Moreover, it finds application in the automotive industry for sealing car trunks, windows, and other areas prone to water intrusion Moreover, it finds application in the automotive industry for sealing car trunks, windows, and other areas prone to water intrusion butyl rubber waterproof tape.

butyl rubber waterproof tape.

butyl rubber adhesive tape. The tape is also resistant to chemicals, which makes it suitable for use in industrial environments where it may come into contact with oils, solvents, and other chemicals.

butyl rubber tape supplier. Scapa Group Specializing in adhesive solutions, Scapa offers custom-made butyl rubber tapes that cater to specific customer requirements. Their tapes are widely used in the solar, automotive, and construction sectors.

butyl rubber tape supplier. Scapa Group Specializing in adhesive solutions, Scapa offers custom-made butyl rubber tapes that cater to specific customer requirements. Their tapes are widely used in the solar, automotive, and construction sectors.Interface

Silicone self-adhesive tape, also known as silicone tape or self-fusing silicone tape, is a remarkable material that is made from high-quality silicone rubber. It boasts unique properties that set it apart from traditional tapes, such as electrical tape or duct tape. This silicone tape is self-fusing, which means that when it is stretched and wrapped around an object, it bonds to itself, creating a watertight and airtight seal without the need for adhesives or glues.

Rubber tapes are generally non-adhesive, and are either equipped with a liner or are linerless. Stretched and overlapped layers will fuse or bond together to form an effective electrical insulation and moisture barrier. For low-voltage (1000V or less) applications, rubber tapes should be stretched during wrapping so that tape width is reduced to approximately 75%. For high- and medium-voltage applications — where the electrical stresses are high (e.g. connector areas, lug areas, and cable shield cut-back areas) — tape should be stretched just short of its breaking point.

One of the primary advantages of flame retardant tapes is their application in electrical insulation. In electrical engineering, the use of heat-resistant tapes mitigates the risks associated with overheating wires and components. By providing a protective barrier, these tapes not only prevent short circuits but also safeguard against potential fire hazards. Industries such as automotive manufacturing, aerospace, and electronics heavily rely on these tapes to ensure compliance with safety standards and regulations.