china centrifugal vertical slurry pump factories

Latest articles

Consider the pump components

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read MoreA variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read MoreAs new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumpsxa0help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read MoreWZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read MoreThe mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read MoreSlurry Pump Speed

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read Morereduce the discharge pressure of the pump to the lowest possible point, and.

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read MoreCorrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read MoreThe size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

china centrifugal vertical slurry pump factories...

china centrifugal vertical slurry pump factories 【china centrifugal vertical slurry pump factories】

Read More

Popular articles

- - Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

- Slurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

- >TL FGD Pump

- All products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

- Depending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

- Slurry Pump Considerations

Latest articles

-

Slurry Pump Considerations

-

-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

-

For certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

-

The terms flushing and quench, often seem to be confused or misused when discussing seal support schemes for , slurry pumps, . As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

-

What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

-

Slurry pump construction materials

Links

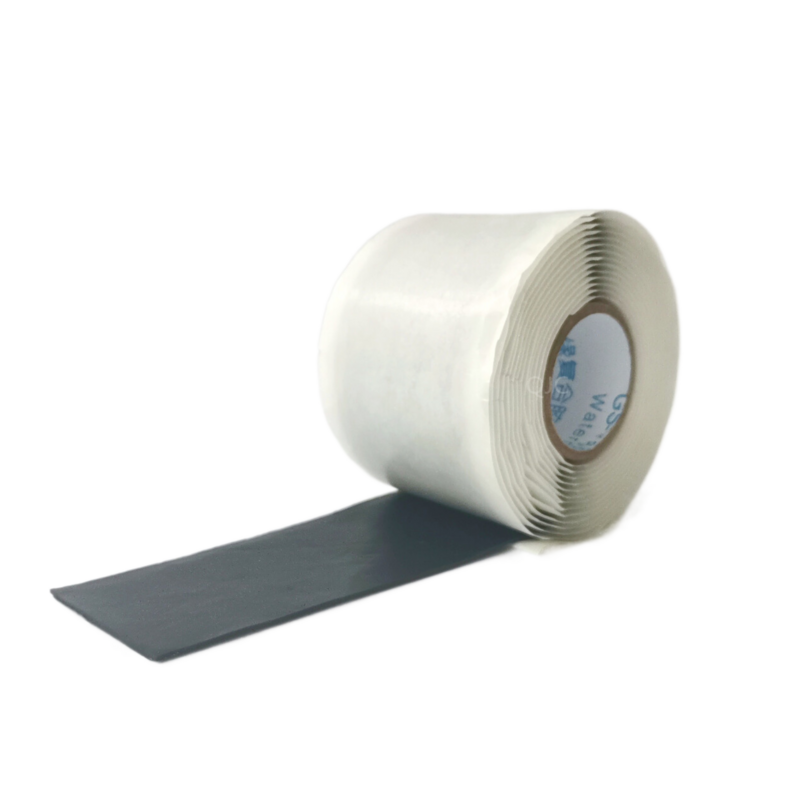

- The versatility of flex tape measuring 12 inches by 10 inches has made it an indispensable tool in the world of crafting. Its flexibility, durability, variety, ease of use, and environmental benefits have earned it a place in the hearts of countless artists and creators. As the crafting community continues to grow and evolve, flex tape will undoubtedly remain a staple in their arsenal of tools.

However, it might be more cost-effective in the long run as it reduces the need for frequent replacements However, it might be more cost-effective in the long run as it reduces the need for frequent replacements

However, it might be more cost-effective in the long run as it reduces the need for frequent replacements However, it might be more cost-effective in the long run as it reduces the need for frequent replacements black electrical tape price.

black electrical tape price.The chemical resistance of silicone insulation tape is another noteworthy feature. It is resistant to moisture, UV rays, and various chemicals, ensuring that it performs reliably in diverse environmental conditions. This makes it suitable for both indoor and outdoor applications, from sealing around electrical conduits to insulating components in marine and automotive settings.

silicone insulation tape

When applied to clean, dry surfaces, the butyl rubber adheres tenaciously, creating a strong, seamless bond that resists peeling or cracking When applied to clean, dry surfaces, the butyl rubber adheres tenaciously, creating a strong, seamless bond that resists peeling or cracking

When applied to clean, dry surfaces, the butyl rubber adheres tenaciously, creating a strong, seamless bond that resists peeling or cracking When applied to clean, dry surfaces, the butyl rubber adheres tenaciously, creating a strong, seamless bond that resists peeling or cracking butyl foil tape. This ease of use, combined with its resilience, makes butyl foil tape a favorite among professionals and DIY enthusiasts alike.

butyl foil tape. This ease of use, combined with its resilience, makes butyl foil tape a favorite among professionals and DIY enthusiasts alike.Conclusion

Surface features are the different types of surfaces on the non-adhesive side or the tape. Tape surface features include non-slip grip, easy to write on surfaces, and reinforced layers for extra strength. To decide what surface features you want, you need to consider how you intend to use the tape. Non-slip grip is great for boxes that will be handled frequently, while easy to write on, non-smudge surfaces are ideal for labeling.

Applications of Fire-Resistant Electrical Tape

electrical tape fire resistant

Material: Ethylene propylene rubber

Checking that it meets these standards is crucial when selecting a control box. It’s not just about regulatory compliance; it’s about ensuring the longevity and reliability of your electrical systems.

The list of applications and machines that can benefit from control boxes is virtually endless. The underlying list highlights the most prominent uses of control boxes today;

rubber flexx tape. The tape bonds quickly and securely, forming a tight seal that will hold up under even the toughest conditions. It can also be easily removed and repositioned if necessary, making it a convenient and practical choice for a wide range of repair jobs.

J50 High-voltage EPR Rubber Tape

Silicones have been used to formulate adhesive products for decades due to their flexibility, temperature cycling resistance, chemical resistance, and wide range of possible material properties.