high quality warman vertical sump pump supplier

Latest articles

Working principle

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read MoreWhen flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read MoreTypes of damage to slurry pumps

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read More3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read MoreThese mud pumps can pump not only sand, but also more mud. They are very effective in pumping all forms of mud, gravel, concrete, slurry, slush, etc.

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read MoreSlurry pump design

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read MoreIf a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read MoreAs described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

high quality warman vertical sump pump supplier...

high quality warman vertical sump pump supplier 【high quality warman vertical sump pump supplier】

Read More

Popular articles

- Settling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

- The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

- sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- Types of slurry pump installation.

- How Slurry Pumps Differ From Standard Pumps?

- How Slurry Pumps Differ From Standard Pumps?

Latest articles

-

Slurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

-

Mixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

-

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

-

Non-settling slurries consist of very fine particles that do not settle to the bottom of the pipe and do not settle for very long (i.e. weeks).

-

Corrosiveness of the slurry

-

Slurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

Links

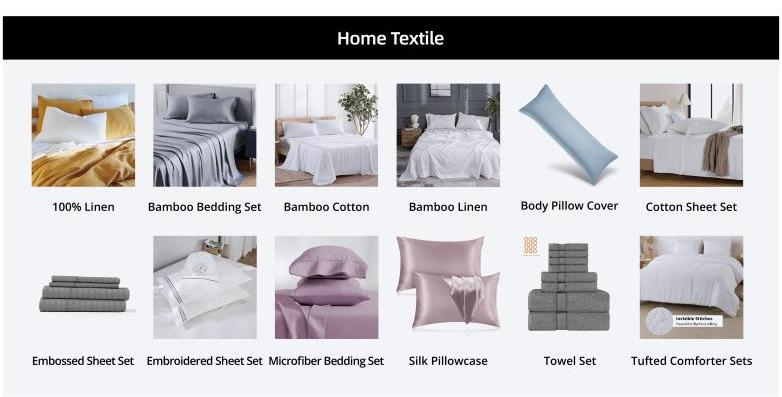

The plain or twill weave of flannel sheets also makes them soft and pliant — all the more reason to use them in colder weather.

Thread count, GSM and momme

- The beauty of washed cotton lies in its ability to provide both luxury and practicality. The pre-washing treatment ensures that these sheets will maintain their softness even after multiple washes, unlike conventional cotton which can sometimes become rough over time. Moreover, the washing process also increases the fabric's resistance to shrinkage, ensuring that your sheets retain their shape and size, even after repeated use.

cotton polyester percale sheet sets. They are not only stylish but also practical, as their durability makes them suitable for everyday use. The easy-care nature of these sheets is particularly appealing to busy individuals or families who prefer low-maintenance bedding.

cotton polyester percale sheet sets. They are not only stylish but also practical, as their durability makes them suitable for everyday use. The easy-care nature of these sheets is particularly appealing to busy individuals or families who prefer low-maintenance bedding.In bedding sheets, high thread count cotton bed sheets are key to achieving a good night’s rest. This is because higher thread counts result in a tighter cotton weave, making the fabric smooth and silky to the touch.

Egyptian cotton is recognised as the finest cotton for bed linen the world over and it’s our favourite! Bed linen made from Egyptian cotton is strong, light and breathable. One of the great benefits of Egyptian cotton is that the feel improves with use and with each wash.

Bath Robe:

Flannel Sheets

Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests

Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests Napkins, runners, and tablecloths not only serve a functional purpose but also create a visually appealing setting for guests