high pressure slurry pump supplier

Latest articles

What style of pump is suitable?

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read MoreSelecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read MoreSelecting And Operating A Slurry Pump

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read MoreUnderwater installation

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read Morereduce the discharge pressure of the pump to the lowest possible point, and.

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read MoreCapacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read More-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read MoreNatural rubber is an excellent wear material when handling wet sand slurries. Its strength, resilience and cut resistance have a positive impact on the wear performance of slurry pumps.

high pressure slurry pump supplier...

high pressure slurry pump supplier 【high pressure slurry pump supplier】

Read More

Popular articles

- >Slurry Pump

- A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

- The construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

- Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

- Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

- Selecting a dredge pump

Latest articles

-

Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

-

How much solids damage can the customer tolerate?

-

>Slurry Pump VS Mud Pump

-

Slurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

-

Better safety

Links

3. Adjustable Stitch Length and Tension Professional upholstery projects often require different stitch lengths and tension settings. A good commercial sewing machine allows you to adjust these settings according to the fabric type and thickness, enabling you to achieve the desired finish.

- When it comes to sewing leather, choosing the right industrial sewing machine needles is crucial. Leather is a tough and durable material that requires special needles that can penetrate through its thickness without causing damage to the fabric. In this article, we will discuss the importance of using the correct needles for sewing leather and provide some tips on how to choose the best ones for your project.

1. Choosing the Right Machine and Needles

In the end, both handheld and heavy-duty sewing machines have their place in the world of sewing. The best sewing machine for you is the one that empowers you to unleash your creativity and achieve your sewing aspirations. So, assess your needs, consider your budget, and choose the sewing machine that will be your perfect partner on your sewing journey.

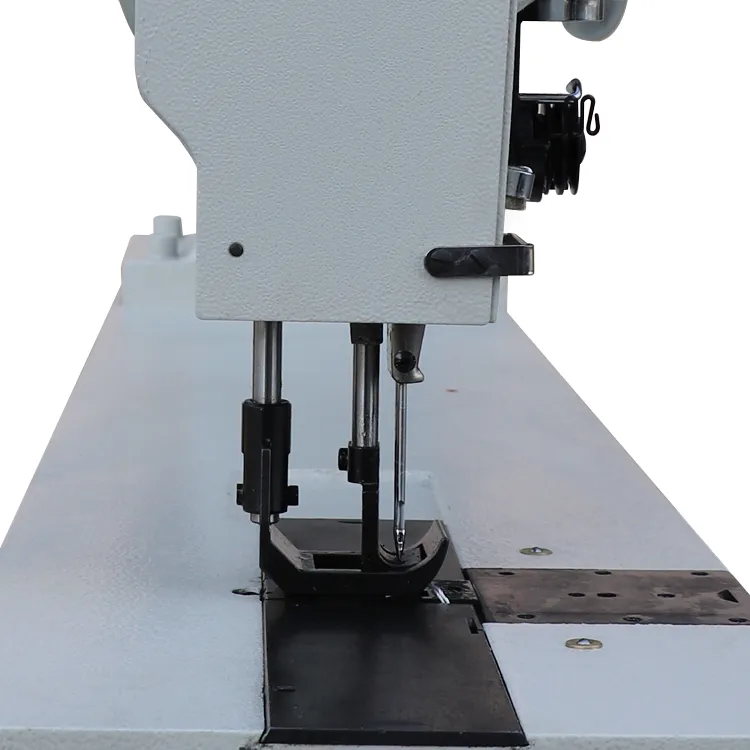

In conclusion, the double needle is a powerful tool in the arsenal of any serious sewist. It combines practicality with artistry, allowing users to create beautiful, professional-quality finishes that are both functional and stylish. Whether you are a seasoned professional or a passionate hobbyist, incorporating a double needle into your sewing repertoire can open up a world of creative possibilities. As sewing continues to evolve with trends in fashion and technology, the double needle remains a timeless tool, empowering sewists to bring their visions to life with precision and flair.

The Beauty of Sewing Machine Quilt Patterns

In conclusion, the automatic buttonhole sewing machine is a game-changer in the sewing industry. Its ability to produce flawless buttonholes quickly and efficiently has made it a vital tool for both hobbyists and professionals alike. As sewing continues to grow as a popular pastime and profession, investing in an automatic buttonhole machine is a smart move for anyone looking to elevate their sewing projects. Whether for creating personal garments or embarking on a business venture, this machine promises to enhance creativity and efficiency, making it a worthy addition to any sewing toolkit.

A double needle sewing machine is equipped with a specialized needle that features two needle points on a single shank. This unique design enables the sewing machine to create two parallel rows of stitching simultaneously, which can add both functional and aesthetic value to sewing projects. The double needle is commonly used for hems, decorative stitching, and other applications where two lines of stitching are beneficial.

1. Increased Efficiency Using appropriate strong needles can enhance sewing efficiency. Needles designed for heavy fabrics can move through the material with ease, reducing the risk of breakages or skipped stitches. This efficiency is particularly important for professional seamstresses or those who undertake large sewing projects.

However, it’s important to note that sewing with a double needle does come with its challenges. It requires a steady hand and attention to detail, as any misalignment can result in crooked stitches. Additionally, not all sewing patterns are suitable for double needle use, so it’s essential to read the instructions carefully before proceeding.

Adjustability for Light Fabrics

How It Works

Heavy Duty Sewing Machines: They’re faster than regular machines but not as quick as industrial ones. They can work with rigid materials but might need breaks so they don’t overheat.

In recent years, the demand for eco-friendly products has surged, leading to a significant increase in the production of jute bags. These bags, made from natural jute fibers, are favored by consumers and retailers alike for their sustainability and durability. As a result, the need for efficient manufacturing processes has prompted many entrepreneurs to invest in jute bag sewing machines. In this article, we will explore the factors influencing the prices of jute bag sewing machines, the average costs, and the benefits of investing in these machines.

For those who frequently work with heavy fabrics like denim, canvas, or leather, the double needle walking foot sewing machine is a game-changer. Traditional machines often struggle to handle bulky materials, leading to skipped stitches and uneven seams. However, the combination of a walking foot and double needles provides the necessary power and stability to navigate these challenging textiles with ease.

Investing in bulk bag sewing machines is also a decision centered around durability. These machines are built to withstand the rigors of industrial environments, which often include dust, debris, and high operational stress. Regular maintenance and adherence to manufacturer guidelines can prolong the lifespan of these machines, ensuring that the initial investment proves valuable over time.

One of the standout features is its ability to operate at high speeds, allowing manufacturers to keep pace with production demands while maintaining precision. Additionally, the machine features adjustable stitch length settings, enabling operators to customize the cutting process according to the specific fabric types and requirements. Many models also come with a built-in thread trimmer, which significantly enhances productivity by eliminating the need for manual cutting of threads after sewing.

3. Cylinder-Bed Machines These machines are designed for working on tubular or circular leather items, such as sleeves or hems. Their unique design allows for flexibility and ease of operation when handling leather that may be difficult to manage on a flatbed machine.

Applications

2. Improved Accuracy Precision is critical in garment manufacturing. Auto cutter sewing machines utilize computer-controlled cutting technology that minimizes human error. This ensures that fabric pieces are cut exactly according to specifications, leading to better fit and finish in the final garments. The consistent accuracy of cuts also reduces fabric waste, significantly benefiting the environment and reducing costs.

In the ever-evolving world of sewing, the long arm zig zag sewing machine stands out as a revolutionary tool for both hobbyists and professional seamstresses alike. This versatile machine combines the features of long arm sewing with the capabilities of zig zag stitching, making it an essential ally for those who take their sewing projects seriously.

The versatility of an overlocker extends beyond seam finishing. Many models come equipped with the capability to create various stitch types, including rolled hems and flatlock stitches. A rolled hem is perfect for delicate fabrics such as chiffon and silk, adding a refined edge without bulk. On the other hand, flatlock stitches are excellent for joining fabrics, especially in activewear, as they provide a comfortable, minimal-seam finish.

what is an overlocker for

Chain stitch sewing is not only a practical sewing technique but also an artistic endeavor allowing for creative exploration. Whether used for constructing everyday garments, creating intricate embroidery, or designing unique textile art, chain stitches have made their mark in both fashion and craft. As technology continues to evolve, so does the potential for new applications of this timeless technique. Embracing the charm and utility of chain stitch sewing opens a world of possibilities for anyone passionate about sewing and textiles. Whether you are a novice or an experienced seamstress, incorporating chain stitching into your repertoire can enhance your projects and spark new inspirations.

Maintenance and Care

Sewing with heavy canvas can pose some challenges due to its thickness and texture. The key is to use the right tools and techniques. First and foremost, a heavy-duty sewing machine is essential. Standard machines may struggle to handle the thickness. Look for machines that offer powerful motors and the ability to adjust presser foot pressure for optimal fabric feed.

Troubleshooting Common Issues with Heavy Duty Sewing Machines

In addition to durability, these machines are also designed with user-friendliness in mind. They come equipped with features like automatic needle threading, easy stitch selection, and adjustable presser foot pressure, making sewing a breeze for even the most inexperienced users.