china hydraulic submersible dredge pump manufacturers

Latest articles

Slurry Pump Selection

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read More>Dredge pumps are a special category of pumps used in the dredging process. Dredging is the process of transporting submerged sediments (usually sand, gravel or rock) from one area to another. Dredging takes place in the shallow waters of lakes, rivers or seas for land reclamation, dredging, flood control, new harbours or expansion of existing harbours. The various industries that use dredge pumps are therefore the construction industry, mining, the coal industry and the oil and gas industry.

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read MoreHorizontal pumps are the most commonly used type of slurry pump and therefore have the advantage of being easy to install or maintain, a wide range of flow parameters to choose from and a wide range of design materials to choose from. One of the advantages of vertical pumps, however, is the relatively small amount of floor space required for installation.

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read MoreStep 3

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read MoreTypes of slurry pumps

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read MoreWhat is the optimum seal arrangement for the application?

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read MoreChromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read MoreConsider the following.

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read MoreIt is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read MoreFind the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

china hydraulic submersible dredge pump manufacturers...

china hydraulic submersible dredge pump manufacturers 【china hydraulic submersible dredge pump manufacturers】

Read More

Popular articles

- Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

- Carbon transfer

- - Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

- Slurry Pump selection

- As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

- Pump selection for FGD

Latest articles

-

The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

-

In this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

-

Other manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

-

All products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

-

The concentration of solids in the slurry - measured as a percentage of the total volume.

-

Dredge pumps are designed to transfer large quantities of fluids and solids.

Links

Challenges and Considerations

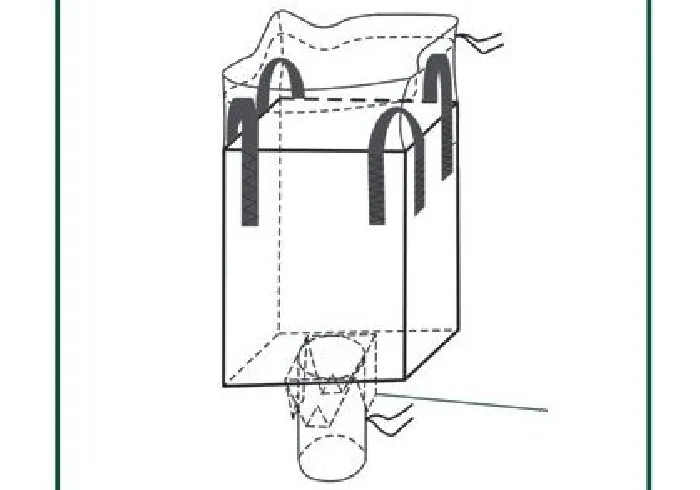

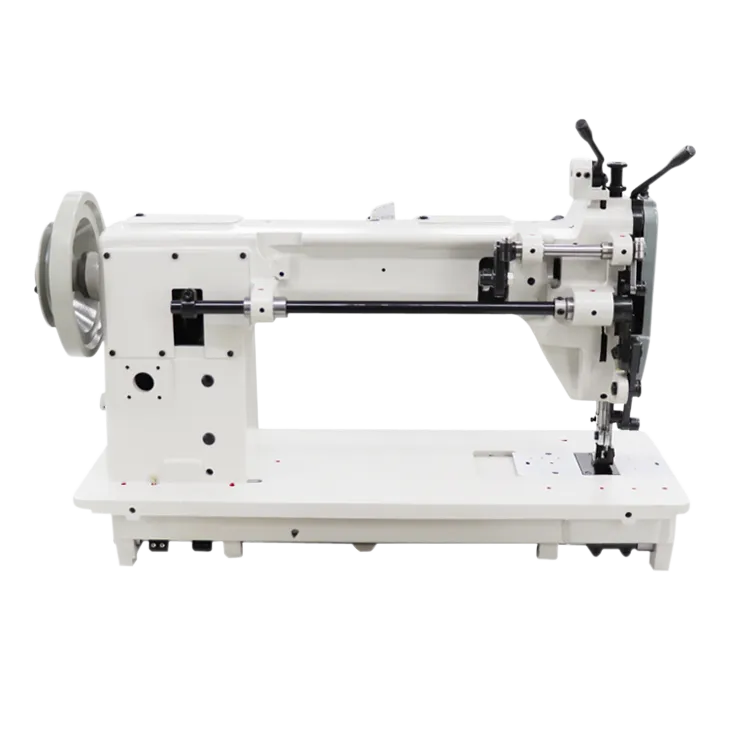

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

Lockstitch sewing machines are used in a multitude of applications within the textile industry. They are frequently utilized in garment construction, where they play a pivotal role in assembling pieces of fabric into finished products. Additionally, they are used for topstitching, hemming, and sewing patch pockets onto garments. Beyond clothing, lockstitch machines are also employed in upholstery, creating strong seams for furniture coverings, and in the production of accessories like bags and belts.

In summary, the single needle lockstitch machine stands as a fundamental tool in the sewing world. Its blend of ease of use, efficiency, and versatility makes it an indispensable asset for both home sewers and professional manufacturers. As technology continues to evolve, the core principles of the lockstitch machine remain relevant, ensuring that it will continue to be a key player in the fabric of the garment industry for years to come. For anyone interested in sewing, whether for personal enjoyment or professional purposes, mastering the use of a single needle lockstitch machine is a valuable skill that unlocks the door to countless creative possibilities.