slurry pump centrifugal supplier

Latest articles

The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read MoreCustomised pumps

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read MoreSlurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport.

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read MoreIs the discharge configuration suitable for abrasive slurries?

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read MoreAlthough the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read MoreFollow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read MoreSlurry Pump

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read MoreWhat style of pump is suitable?

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read MoreAnother important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

slurry pump centrifugal supplier...

slurry pump centrifugal supplier 【slurry pump centrifugal supplier】

Read More

Popular articles

- Slurry Pump

- The terms slurry pump and dredge pump can be used interchangeably.

- 3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

- Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

- Determine the size of the pump

- WL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

Latest articles

-

Desire for higher efficiency than centrifugal pumps

-

Pumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

-

Damage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

-

In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

-

Slurry pump seals

-

With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

Links

Good sealing performance

Understanding the Basics

In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather

In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather In winter, they can help retain heat inside your home by providing an extra layer of insulation against the cold weather windows roller. This not only saves money on energy bills but also reduces your carbon footprint.

windows roller. This not only saves money on energy bills but also reduces your carbon footprint.Window: sliding windows (including left and right sliding windows, up and down sliding windows), casement windows (including inner and outer windows) and top-hung windows.

1. Sliding windows has beautiful appearance; large window width, large glass block, wide field of vision, high daylighting rate; flexible and safe use; long service life; open in a plane and occupy less space;

2. Casement windows are characterized by large opening area and ventilation; good airtightness, sound insulation, heat preservation, and strong impermeability;

3. Top-hung windows are characterized by ventilation and safety. It is widely used in buildings;

4. Thermal Break Aluminum Window.

Main gate iron gate designs offer a wide array of possibilities, ranging from classic and ornate to modern and minimalist. The timeless charm of wrought iron, with its durability and malleability, allows artisans to craft intricate patterns and shapes, making each gate a unique piece of art. These designs often incorporate scrolls, leaves, floral motifs, or even customised elements reflecting the owner's interests or the heritage of the property.

The ergonomic design of many steel door pull handles ensures easy operation, ensuring a comfortable grip. Many handles are crafted to facilitate smooth pulling and pushing motions, which reduces the risk of accidents in both home and workplace settings. In addition, the installation of steel handles does not require specialized tools, making them user-friendly right from the onset.

Recycling wrought iron helps conserve natural resources and reduces the environmental impact associated with mining and processing new materials. By choosing to recycle, you contribute to environmental sustainability and help reduce landfill waste.

The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish

The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish cast basket.

cast basket.Cast Iron Railing Panel

3. Design Versatility Aluminium is well-known for its strength and adaptability. Thermal break aluminium profiles can be engineered into various designs and styles, making them suitable for a wide range of architectural applications, from sleek modern designs to more traditional aesthetics. Additionally, they can be coated in different finishes, allowing for greater personalization.

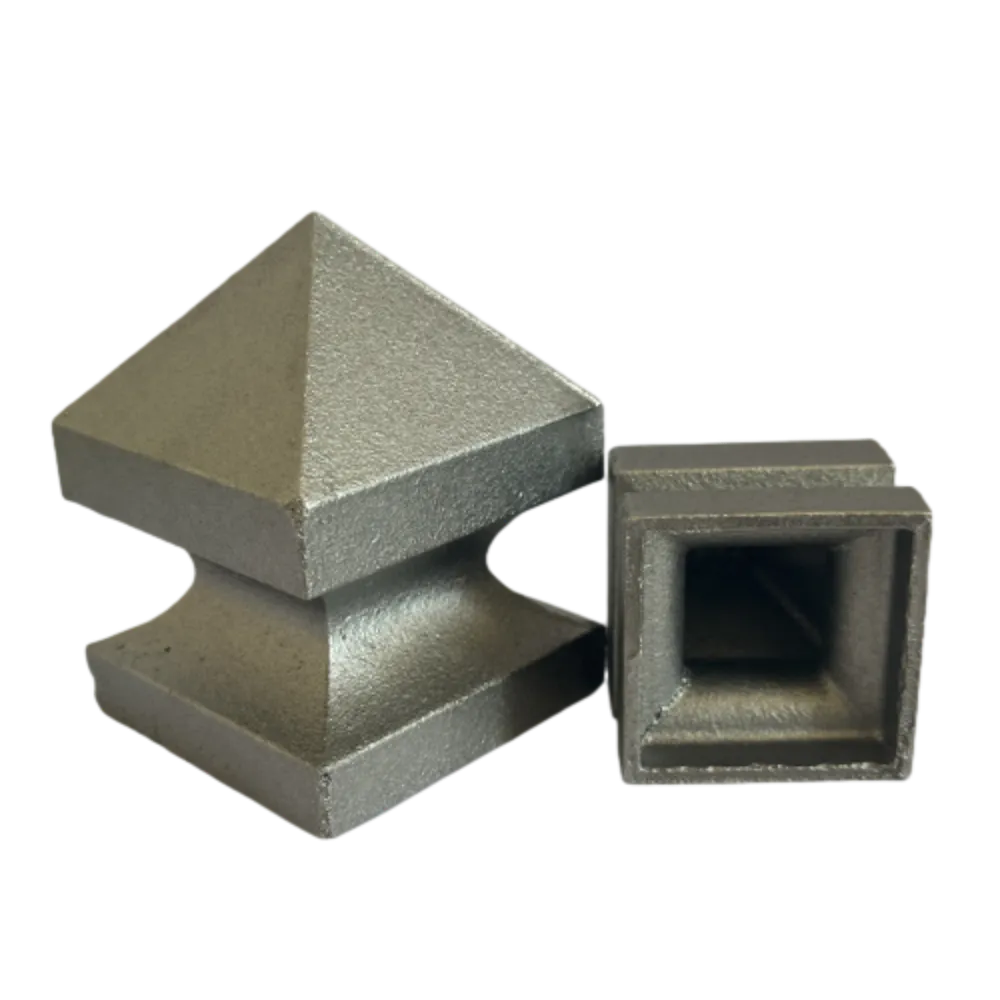

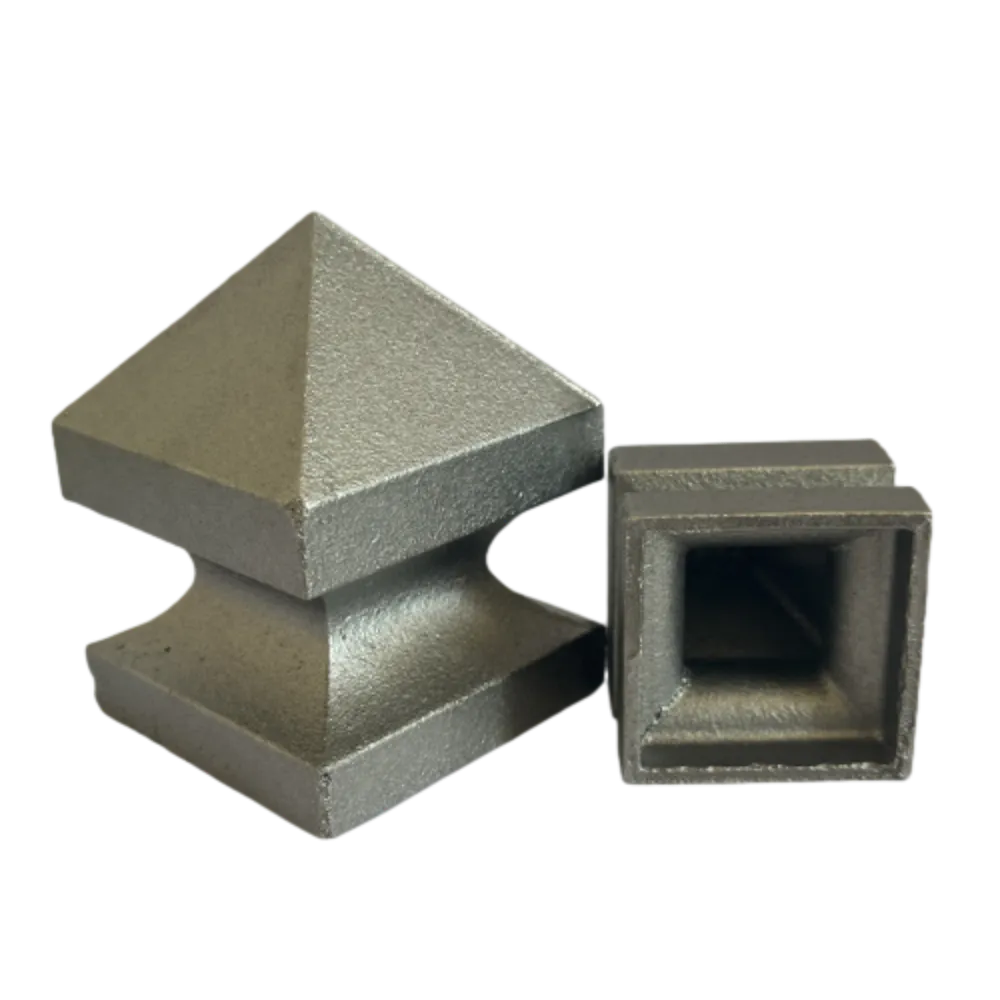

Finials are decorative elements that can be added to the top of the fence posts or pickets. They serve as the finishing touch for wrought iron fences, providing an opportunity for personalization. Styles can range from simple spheres or pointed designs to elaborate designs featuring leaves, flowers, or other motifs. Finials add a touch of flair while also serving to discourage climbing.

Maintenance of metal door knobs is relatively straightforward, another reason for their popularity. Regular cleaning with a gentle soap solution helps remove dirt buildup and prevents tarnishing. For brass knobs, occasional polishing can restore their luster, while stainless steel knobs typically just require a quick wipe down to keep them looking their best. This ease of maintenance makes them a practical choice for busy homeowners or property managers.

Cast Iron Railing Panel

Aluminum sliding door rollers play an indispensable role in the functionality and aesthetics of sliding doors. Understanding the types, benefits, and maintenance needs of these rollers can enhance your overall experience with aluminum sliding doors, ensuring they remain stylish and functional for years to come. By investing in quality rollers and taking proper care of them, homeowners can enjoy the benefits of seamless access and an elegant living space.

Welding, an integral part of the manufacturing and engineering world, often brings to mind images of fiery sparks and molten metal. However, the process is not just about joining pieces together; it's a symphony of art and science, where even the most minute details, like metal leaves, play a crucial role. In this context, 'metal leaves for welding' refers to the technique of using thin, metallic sheets or 'leaves' as a part of the welding process, particularly in artistic and intricate welding applications.