centrifugal dredge pump manufacturer

Latest articles

From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read MoreIn this article, we will present practical guidelines and rules for slurry centrifugal pumps. We will also discuss key operating characteristics, material selection and other considerations.

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read MoreWhat is a slurry pump?

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read MoreParticle size, shape and hardness (impact on wear and corrosion potential of pump components)

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read MoreAier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read MoreVertical Slurry Pumps Pump Sewage More Efficiently

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read MoreAnother way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read MoreWith the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

centrifugal dredge pump manufacturer...

centrifugal dredge pump manufacturer 【centrifugal dredge pump manufacturer】

Read More

Popular articles

- How to Choose a Dredging Pump or Slurry Pump

- If you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

- The same point of slurry pump and mud pump

- A slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

- Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

- Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

Latest articles

-

Slurry Pump Impeller Size

-

of a thick consistency, and.

-

Consider the following.

-

Find a professional slurry pump supplier

-

Heavy-Duty Slurry Pump

-

The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

Links

Pros And Cons Of Linen

Bedspreads

They are versatile and can easily adapt to changing decor styles, making them a practical choice for many They are versatile and can easily adapt to changing decor styles, making them a practical choice for many

They are versatile and can easily adapt to changing decor styles, making them a practical choice for many They are versatile and can easily adapt to changing decor styles, making them a practical choice for many bedding designs. Meanwhile, luxury bedding designs, often featuring high thread count sheets and plush fabrics, promise unparalleled comfort and a touch of indulgence.

bedding designs. Meanwhile, luxury bedding designs, often featuring high thread count sheets and plush fabrics, promise unparalleled comfort and a touch of indulgence.Keeps you cool due to longer fibers

Weave Patterns

Joseph Jacquard invented this weaving technique in 1804. A special loom is used to weave a pattern directly into the fabric.

COVERLET

Joseph Jacquard invented this weaving technique in 1804. A special loom is used to weave a pattern directly into the fabric.

The quick-drying nature of the material also makes them low maintenance, a feature that many busy men appreciate The quick-drying nature of the material also makes them low maintenance, a feature that many busy men appreciate

The quick-drying nature of the material also makes them low maintenance, a feature that many busy men appreciate The quick-drying nature of the material also makes them low maintenance, a feature that many busy men appreciate men's bathrobe waffle weave.

men's bathrobe waffle weave. It can be used to create a variety of different looks, from classic and traditional to modern and contemporary It can be used to create a variety of different looks, from classic and traditional to modern and contemporary

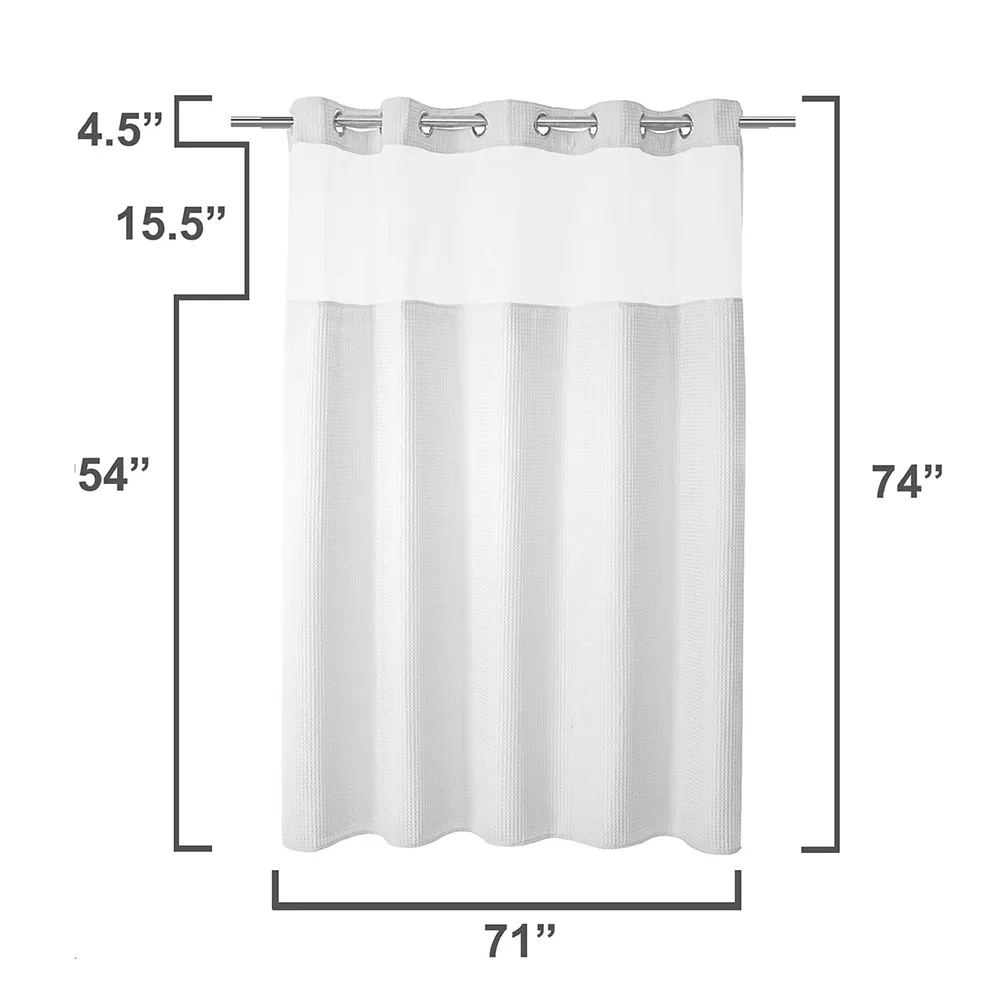

It can be used to create a variety of different looks, from classic and traditional to modern and contemporary It can be used to create a variety of different looks, from classic and traditional to modern and contemporary wide fabric for bedding. For example, you could use wide fabric to make a sumptuous bedspread or comforter, or you could use it to create custom curtains or window treatments. The possibilities are virtually endless, allowing you to truly personalize your sleeping space to reflect your own unique style and taste.

wide fabric for bedding. For example, you could use wide fabric to make a sumptuous bedspread or comforter, or you could use it to create custom curtains or window treatments. The possibilities are virtually endless, allowing you to truly personalize your sleeping space to reflect your own unique style and taste.THROW