china anti abrasive sand slurry pump

Latest articles

Typical Applications of slurry pump

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read MoreWith the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read More>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read MoreHorizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read MoreSlurry Pump

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read MoreCritical to the engineering of the pump are heavy duty bearing frames and shafts, extra thick wall sections and easily replaceable wear parts. Total life cycle cost considerations are critical when specifying pumps for severe operating conditions, such as FGD service. High chrome pumps are ideal due to the corrosive pH of the slurry.

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read MoreIf you have experience pumping slurries, you know it's not an easy task. Slurries are heavy and difficult to pump. They cause excessive wear on pumps and their components and are known to clog suction and discharge lines if not moving fast enough. Most importantly, it’s a challenge to make slurry pumps last for a reasonable amount of time. But, there are a few things you can do to extend the life of your slurry pump and make pumping slurry less of a challenge.

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read MoreSlurry Pump

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read MoreAs described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

china anti abrasive sand slurry pump...

china anti abrasive sand slurry pump 【china anti abrasive sand slurry pump】

Read More

Popular articles

- If you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

- Aier Machinery Hebei Co., Ltd. is a large-scale professional >slurry pumps manufacturer, gravel pumps, dredge pumps, sewage pumps and clean water pumps in China.

- 2. All have vertical pumps and horizontal pumps and can convey slurry.

- If you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

- Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

- Series of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

Latest articles

-

Some models can generate discharge pressures up to 260 ft. (80 m).

-

If youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

-

The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

-

Make sure you follow the basic rules of pump piping.

-

There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

-

These conditions include

Links

- One of the primary uses of butyl tape rubber is in the construction industry, where it serves as an efficient waterproofing solution. It is commonly applied on roofs, around windows and doors, and in plumbing systems to prevent water infiltration and leaks. Its ability to conform to irregular surfaces and maintain its seal over time makes it particularly valuable in these applications.

Durability is another significant benefit. PVC insulation tape can withstand extreme temperatures and environmental conditions, ensuring that it maintains its insulating properties over time. This longevity is particularly beneficial for businesses involved in electrical installations, as it translates to reduced maintenance costs and enhanced safety.

- One of the most common types of tape used in construction is measuring tape. This flexible and durable tape is essential for accurately measuring distances and dimensions. Measuring tape comes in various lengths, but the most common lengths are 25 feet and 30 feet. Measuring tape is used by construction workers to measure everything from wall lengths to material dimensions. It is a versatile tool that helps ensure precision during the building process.

- In conclusion, black butyl rubber sealant stands out as a reliable and adaptable solution in multiple industries. Its unique combination of flexibility, adhesion, and resistance to environmental factors ensures that it consistently delivers superior sealing performance. Whether it's safeguarding a building from water damage, sealing critical automotive components, or protecting electronic devices, black butyl rubber sealant remains an indispensable tool in the modern world.

- Brown insulation tape, often referred to as electrical tape, is a versatile and essential tool in the world of electrical work and maintenance. This humble yet crucial material plays a pivotal role in ensuring safety, efficiency, and longevity in various electrical applications.

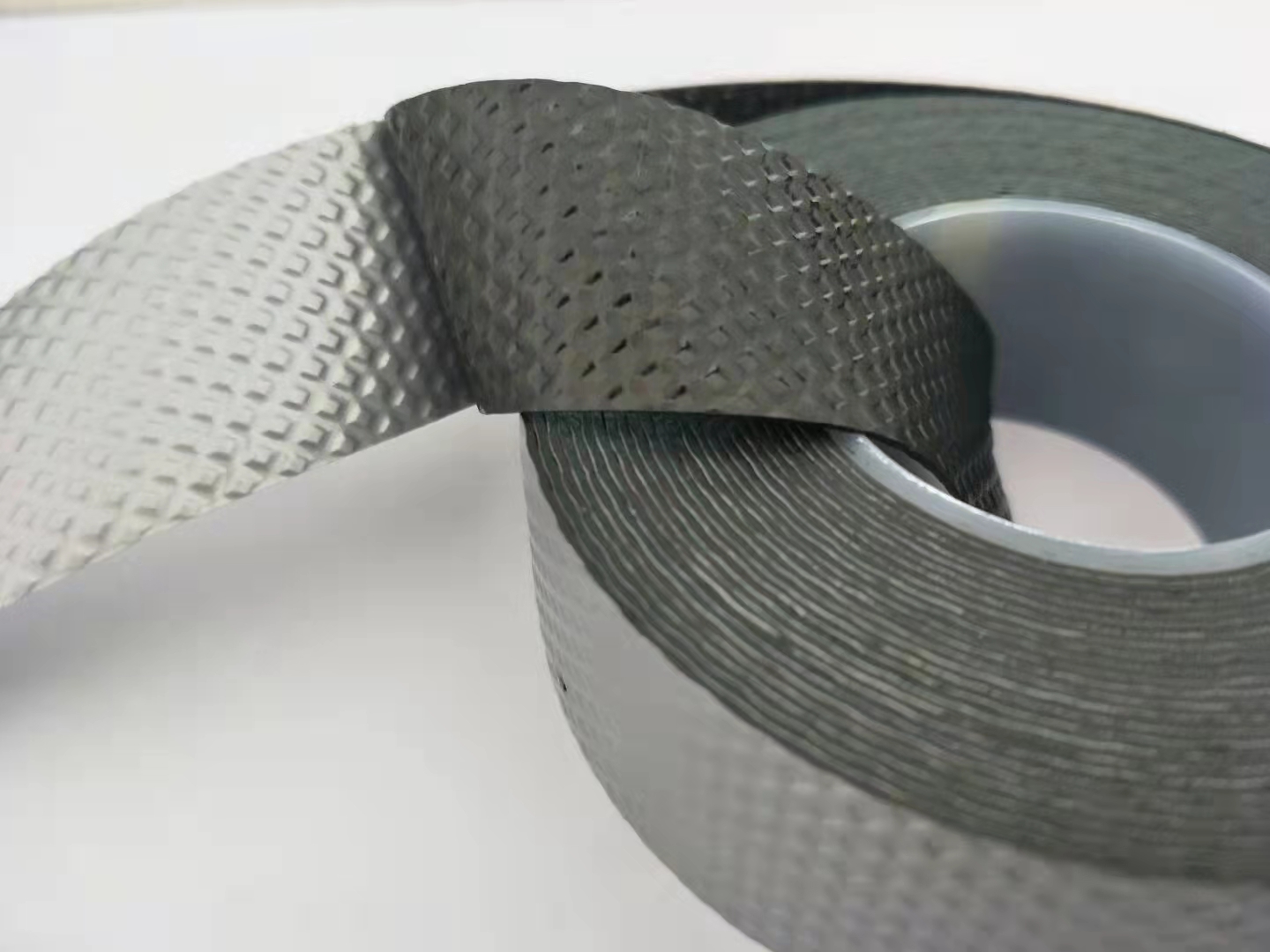

- EPDM Butyl Tape A Versatile and Durable Solution for Various Applications

- Furthermore, self-amalgamating tape is highly durable and resistant to chemicals. It can withstand exposure to oils, fuels, acids, and other harsh substances without losing its sealing properties. This makes it an excellent choice for environments where exposure to chemicals is common, such as chemical plants or refineries.

Another emerging application of flame retardant tapes is in the realm of renewable energy, particularly in the installation of solar panels and wind turbines. These installations often require materials that can withstand high temperatures and environmental stresses. Flame retardant tapes provide essential protection in these settings, helping to maintain the integrity and safety of the energy generation systems.

- In addition to its functional benefits, warehouse marking tape is also cost-effective. Unlike permanent markings that require expensive resurfacing or repainting, floor tape can be easily replaced when worn out or when changes in warehouse layout are necessary. Its low maintenance nature makes it an ideal solution for businesses seeking to optimize their warehouse operations without incurring significant costs.

Repairing leaking pipes and pipe joints

5. Allow the tape to cure Once wrapped, let the tape sit for a few minutes to allow it to cure and create a strong bond. Depending on the type of tape, it may take anywhere from a few minutes to a few hours to fully cure.

1. Inspect the Area Check for any gaps around doors and windows. A simple test is to close a door or window and see if light passes through; if it does, weather stripping is needed.

One of the primary functions of insulation tape is to provide electrical safety. Made from materials that are resistant to electrical currents, yellow insulation tape is commonly used to insulate wires and connections, ensuring safety in electrical installations. Its bright color allows for easy identification and differentiation between various electrical circuits. For safety professionals and electricians, yellow tape often signifies caution or a specific type of wiring, making it an essential tool for clear communication and safety protocol adherence.