china shijiazhuang slurry pump

Latest articles

3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read MoreWhat is a slurry pump?

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read MoreDredge Pump

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read MoreWhen the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read MoreDepending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read MoreVertical Slurry Pumps Pump Sewage More Efficiently

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read MoreCustomised pumps

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read MoreSlurry Pump

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read MoreIdeal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read MoreAdapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

china shijiazhuang slurry pump...

china shijiazhuang slurry pump 【china shijiazhuang slurry pump】

Read More

Popular articles

- From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

- Slurry Pump Considerations

- A clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

- WY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

- Hydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

- Pumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

Latest articles

-

- Keeping clean catch basins clean from solids

-

For pumping abrasive slurries, these types of pumps can also be made from specialised high-wear alloys. Hardened stainless steel is also a common choice for abrasive slurries.

-

A clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

-

A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

-

WL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

-

If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

Links

Introduction

R-996 titanium dioxide, white powder, insoluble in water, non-physiological toxicity, chemically stable, with excellent weather resistance and anti-powdering ability.

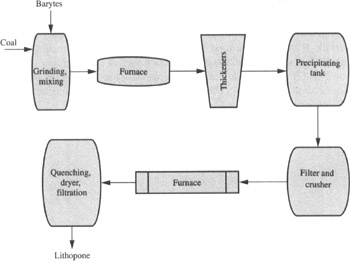

Developing new Lithopone formulations, one that enhances the properties of the existing Lithopone is anticipated to boost the demand for Lithopone white pigment during the forecast period. Reinforced Lithopone is one such development, wherein a copolymer is added to the polymerization reaction to yield Lithopone with an increased weather resistance and an anti-ultraviolet property. Moreover, development of nano-scale Lithopone is also anticipated to attract market interest during the forecast period.

Does It Cause Cancer?

Skin-penetration studies

Wholesale Dio2 Cas 13463-67-

The facility operates under a strict code of conduct that prioritizes ecological preservation and community welfare The facility operates under a strict code of conduct that prioritizes ecological preservation and community welfare

The facility operates under a strict code of conduct that prioritizes ecological preservation and community welfare The facility operates under a strict code of conduct that prioritizes ecological preservation and community welfare 77891 titanium dioxide factory. It actively seeks to reduce its carbon footprint and engages in initiatives that foster biodiversity and support local ecosystems.

77891 titanium dioxide factory. It actively seeks to reduce its carbon footprint and engages in initiatives that foster biodiversity and support local ecosystems.Titanium dioxide has many purposes in both food and product development.

Wholesale Dio2 Cas 13463-67-7

While we have aimed to create an all-encompassing lithopone plant project report, we acknowledge that individual stakeholders may have unique demands. Thus, we offer customized report options that cater to your specific requirements. Our consultants are available to discuss your business requirements, and we can tailor the report's scope accordingly. Some of the common customizations that we are frequently requested to make by our clients include:

This has led to the development of specialized grades tailored to specific industrial requirements This has led to the development of specialized grades tailored to specific industrial requirements

This has led to the development of specialized grades tailored to specific industrial requirements This has led to the development of specialized grades tailored to specific industrial requirements r 298 titanium dioxide factories.

r 298 titanium dioxide factories.Is used as a photocatalyst in solar panels and can also reduce pollutants in the air.

High Scattering Power TiO2 DongFang R5566

In the automotive industry, for example, MBR9668 is used in primers and finish coats to provide superior color retention and gloss. With durability being a key concern for automotive manufacturers, utilizing rutile titanium dioxide in coatings enhances the longevity of the vehicle's exterior finishes, ensuring that they remain vibrant and effective for years under various conditions.

rutile titanium dioxide mbr9668-coating supplier

The rapid method of synthesis described here is readily scalable to the proportions required in cosmetics manufacture.

States looking to ban titanium dioxide as a food additive

Titanium dioxide remains in many food products in this country because of regulatory folly by the Food and Drug Administration, which allows problematic food ingredients to remain undetected and unreviewed.

Lithopone B301, Lithopone B311 powder is also widely applied in paints and enamels