high quality slurry sand pump factories

Latest articles

Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

Read More- Pumping the final product in a process

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

Read MoreMagnetite mixing

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

Read MoreTypical Applications of slurry pump

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

Read MoreWhat is a slurry?

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

Read MoreSlurry Pump

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

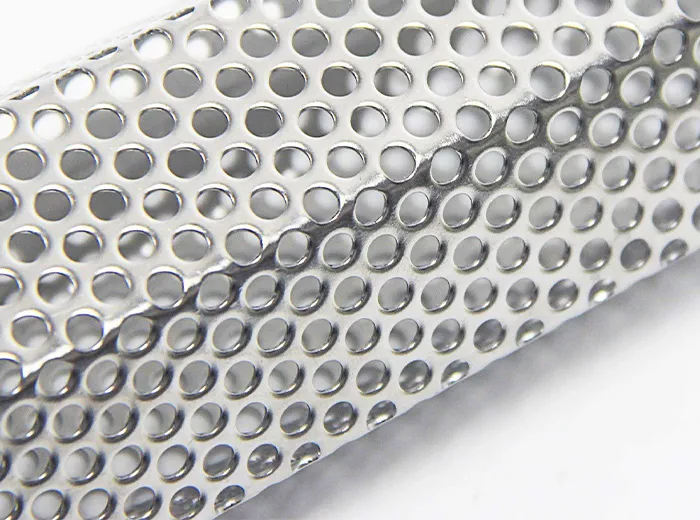

Read MoreNatural rubber is an excellent wear material when handling wet sand slurries. Its strength, resilience and cut resistance have a positive impact on the wear performance of slurry pumps.

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality slurry sand pump factories...

high quality slurry sand pump factories 【high quality slurry sand pump factories】

Read More

Popular articles

- Slurry pump considerations

- The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- Dredge Pump Features

- Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

- Slurry Pump

- It is important that the pump you choose has components that will not wear out from abrasive slurries.

Latest articles

-

Slurry Pump

-

Slurry Pump

-

Choosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

-

Ideal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

-

Slurry pump construction materials

-

What is a slurry?

Links

- Cooking Area Look for a grill with ample cooking space to accommodate multiple food items. Grills with secondary cooking surfaces, such as warming racks, are advantageous.

Fire Starters

The versatility of over fire cooking means that virtually any food can be prepared using this method. From skewered meats and roasted vegetables to baking bread or heating soups, the possibilities are endless. Cookware specifically designed for over fire cooking, such as cast iron skillets and Dutch ovens, allows for a wide range of culinary creations. Moreover, the communal aspect of gathering around the fire encourages social interaction, making meals even more enjoyable.

Health-conscious diners will appreciate the benefits of hanging cooking grates, as this method often requires less oil than traditional frying or grilling techniques. Cooking over an open flame allows fat to drip away from the food, resulting in lighter and less greasy dishes. Additionally, the ability to cook vegetables at the same time as meats can promote a well-balanced diet, encouraging the incorporation of a variety of food groups in every meal.

Benefits of Using a Charcoal Basket

The metal slider attached to the bottom of your charcoal grill is called the intake damper, and it’s your main method for controlling the grill’s heat. This damper controls how much airflow enters through the bottom of the grill. An open intake damper means more oxygen and a hotter-burning fire. Close it completely and the fire will eventually go out.

เตาอบถ่านพกพา ตัวเลือกที่ยอดเยี่ยมสำหรับการปิ้งย่างนอกบ้าน

Safety is another benefit to gas. While charcoal is a safe cooking fuel, some homeowners’ associations or apartment complexes don’t allow charcoal grilling because of potential hazards from loose embers or ash. Working with charcoal requires attention and care at all times!