high quality chemical slurry pump factory

Latest articles

As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read MoreDefinition of dredge and slurry pumps

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read MoreFine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read MoreKeep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read MoreDetermine the operating parameters of the pump.

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read MoreLarger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read MoreBecause of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read MoreProcess speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read MoreAs described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

high quality chemical slurry pump factory...

high quality chemical slurry pump factory 【high quality chemical slurry pump factory】

Read More

Popular articles

- Dredge Pump

- As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

- Customised pumps

- The Company Adopts Advanced Computer Aided Engineering Software

- - Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

- Applications of Rubber Lined Slurry Pumps

Latest articles

-

If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

-

The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

-

Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

-

Expertise and experience

-

The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

-

From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

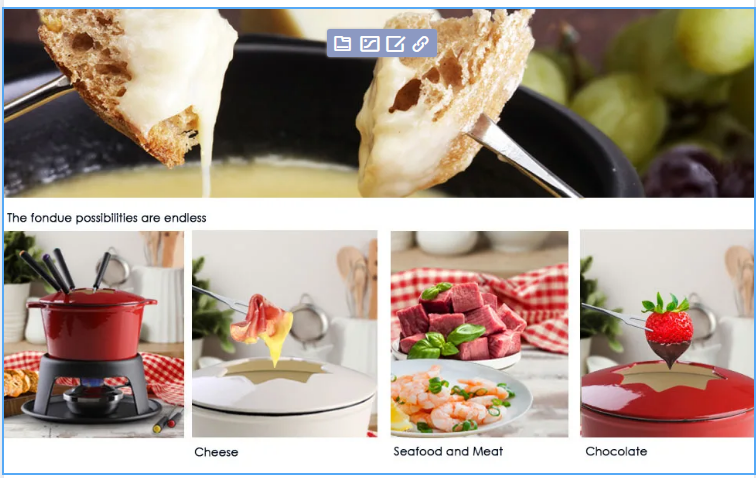

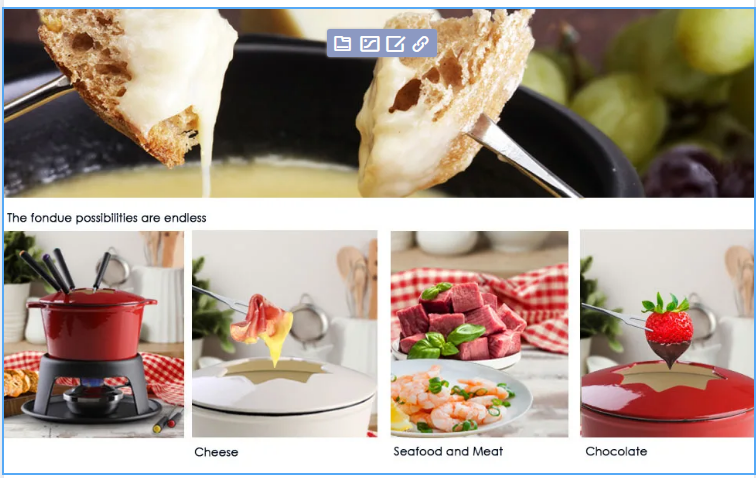

The flared sides also prevent steam from accumulating, hastening cooking by preventing mushy food.

Interactive Presentation: The sizzle and steam emanating from the hot plate or platter create an interactive and sensory dining experience, engaging diners and adding an element of excitement to the meal presentation.

Whether you're cooking up a hearty breakfast of pancakes and bacon, searing a perfect steak for dinner, or grilling vegetables for a healthier meal option, the cast iron grill griddle pan can handle it all Whether you're cooking up a hearty breakfast of pancakes and bacon, searing a perfect steak for dinner, or grilling vegetables for a healthier meal option, the cast iron grill griddle pan can handle it all

Whether you're cooking up a hearty breakfast of pancakes and bacon, searing a perfect steak for dinner, or grilling vegetables for a healthier meal option, the cast iron grill griddle pan can handle it all Whether you're cooking up a hearty breakfast of pancakes and bacon, searing a perfect steak for dinner, or grilling vegetables for a healthier meal option, the cast iron grill griddle pan can handle it all cast iron grill griddle pan.

cast iron grill griddle pan.Best for: everyday cooking: stir-fries, all sorts of vegetables and sauces, and meat

In the realm of culinary craftsmanship, few materials have stood the test of time quite like cast iron. Renowned for its durability, heat retention, and versatility, cast iron cookware has been a staple in kitchens for generations. However, it's the evolution of this classic kitchen essential that has sparked a new wave of interest among chefs and home cooks alike – enter enameled cast iron cookware sets.

frying cast iron skillet. If it's too hot, your food will burn; if it's not hot enough, it won't fry properly. To test the oil's readiness, drop a small piece of bread or a kernel of popcorn into the oil – if it sizzles and browns within a few seconds, the oil is ready.

frying cast iron skillet. If it's too hot, your food will burn; if it's not hot enough, it won't fry properly. To test the oil's readiness, drop a small piece of bread or a kernel of popcorn into the oil – if it sizzles and browns within a few seconds, the oil is ready.

Apply this mixture to the affected areas and use a soft brush to gently scrub Apply this mixture to the affected areas and use a soft brush to gently scrub

Apply this mixture to the affected areas and use a soft brush to gently scrub Apply this mixture to the affected areas and use a soft brush to gently scrub washing cast iron grill pan. The alkaline properties of the baking soda will help break down oils and burnt pieces without harming the iron's protective layer.

washing cast iron grill pan. The alkaline properties of the baking soda will help break down oils and burnt pieces without harming the iron's protective layer.

Versatile Applications: Sizzling steak plates and platters are suitable for serving a wide range of sizzling dishes, including steaks, fajitas, grilled seafood, and sizzling vegetables. They are equally popular in restaurants and home kitchens, adding flair to the presentation of hot meals.