china china vertical sump pump rubber lined manufacturer

Latest articles

There is a better way to pump sewage, overflows and other collected dirty water around the plant.

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read MoreA target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read MoreAs described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read MoreLow slurry flow rates

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read MoreLarger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read MoreReduced inventory

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read MoreSlurry Pump

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read MoreHow does a dredge pump work?

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read More- Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

china china vertical sump pump rubber lined manufacturer...

china china vertical sump pump rubber lined manufacturer 【china china vertical sump pump rubber lined manufacturer】

Read More

Popular articles

- Typically, slurries are.

- Centrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

- Conveying medium

- >Slurry Pump vs Mud Pump

- Slurry Pump

- Working principle

Latest articles

-

Dredge pumps are designed to transfer large quantities of fluids and solids.

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

-

As described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

-

-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

-

Light-duty Slurry Pump

-

The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

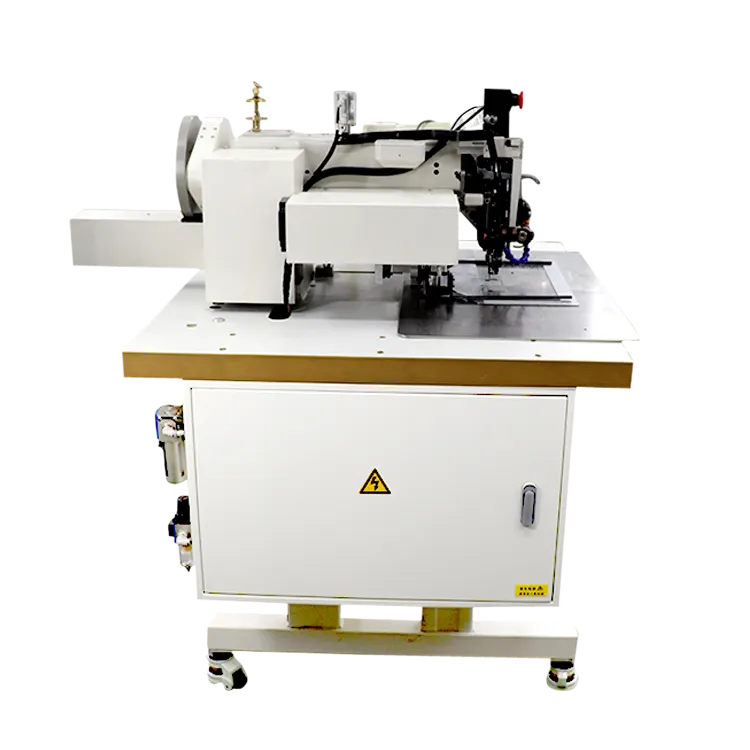

Industrial Long Arm Sewing Machines for Sale A Comprehensive Guide

Furthermore, as automakers evolve towards sustainable practices, automotive sewing machines have adapted to utilize eco-friendly materials without compromising durability. Innovations such as the use of recycled fabrics and bio-based materials are becoming more prevalent, and the sewing machines that fabricate these materials are at the forefront of this transition.

Another noteworthy aspect of cylindrical bed sewing machines is their adaptability to different sewing materials. Whether the fabric is lightweight like chiffon or heavier like denim, these machines can be adjusted to ensure optimal stitch quality. The ability to switch between different types of materials without compromising performance makes cylindrical bed sewing machines a favorite among manufacturers who deal with diverse product lines.

4. Fabric Coasters

Selecting the right needle and thread is critical in heavy-duty sewing. For thicker fabrics, you'll want to use a needle designed for heavy materials, such as a jeans needle or a leather needle. These needles are stronger and have a larger eye to accommodate thicker threads.

heavy duty sewing

When it comes to performance, the CB2500 does not disappoint. Its powerful motor enables smooth and consistent stitching at various speeds, catering to the preferences of different users. The machine’s ability to handle multiple layers of fabric without skipping stitches is particularly noteworthy, making it suitable for both lightweight and heavy materials.

4. Durable Build Quality Given the rugged nature of upholstery work, these machines are constructed from high-quality materials that can withstand the rigors of daily use. A heavy-duty frame and components ensure longevity and reliability, reducing the frequency of repairs.

commercial upholstery sewing machine