high quality submersible water pump 6 inch factories

Latest articles

If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read MoreSlurry Pump Considerations

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read MoreA >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read More- Pumping the final product in a process

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read MoreWZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read MoreChoosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read MoreExamples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read MoreMany types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

high quality submersible water pump 6 inch factories...

high quality submersible water pump 6 inch factories 【high quality submersible water pump 6 inch factories】

Read More

Popular articles

- Consider the following.

- When dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

- As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumps help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- Conveying medium

- Corrosiveness of the slurry

Latest articles

-

A typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

-

For example.

-

target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

-

Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

-

Slurry Pump

-

Some models can generate discharge pressures up to 260 ft. (80 m).

Links

Here are a few signs that you can look for to tell you what a fence is made from:

Recyclable

But don’t underestimate the enduring charm of a well-maintained wrought iron fence. True, it needs more frequent checks for rust and occasional repainting.

- Sliding screen doors are an essential part of many homes, offering convenience and ventilation while keeping insects at bay. However, over time, the rollers, which facilitate smooth movement, can become misaligned or worn, causing the door to stick or drag. Adjusting these rollers is a straightforward task that can be done with minimal tools and a bit of patience. Here's a step-by-step guide to adjusting rollers on a sliding screen door.

Elevate your décor with the timeless elegance of cast iron ornaments. Explore our collection today and discover the perfect pieces to enhance your home or landscape. With their unmatched beauty and durability, cast iron ornaments are sure to make a lasting impression for generations to come.

You can attain this by sliding one feature over the other.

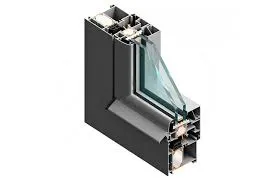

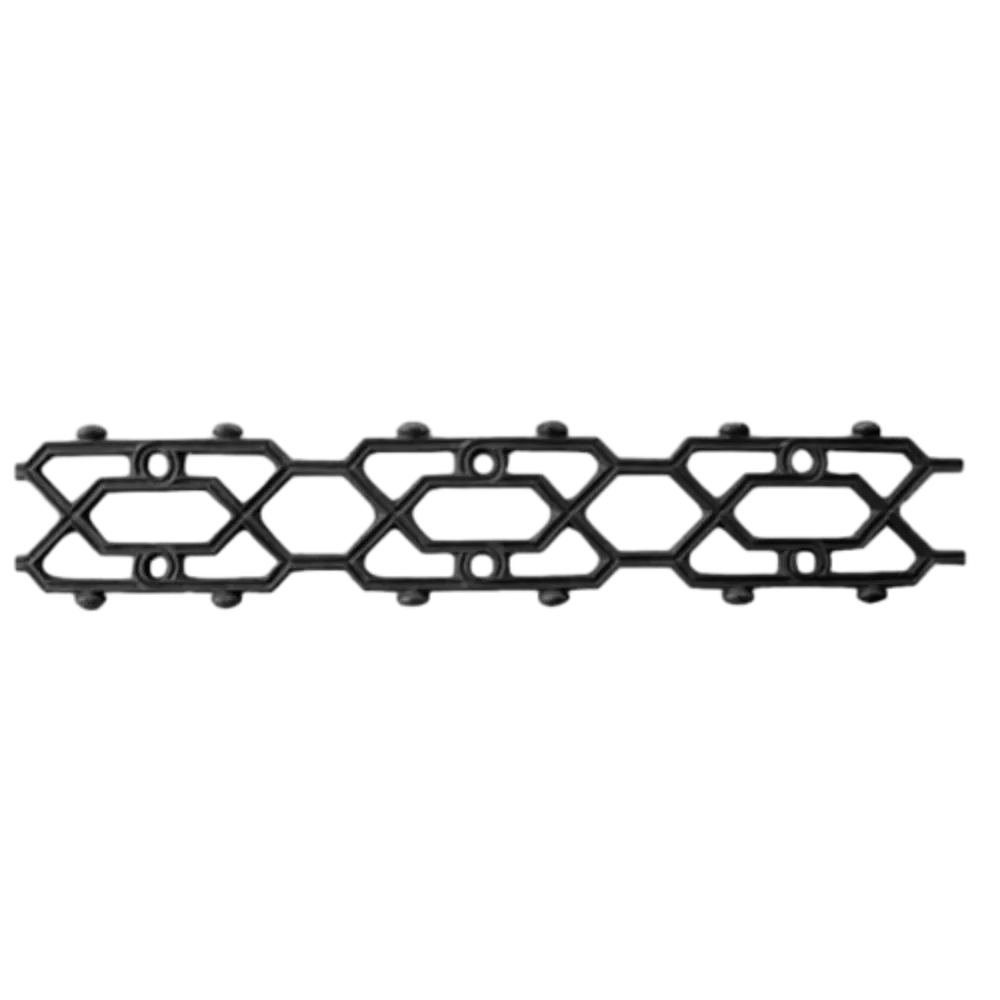

In the case of residential construction, so-called ‘warm’ aluminium profiles are becoming increasingly popular. This means that the profile construction consists of two metal sections, joined by a thermal plastic insert, such as glass fibre-reinforced polyamide. Such a profile generally has three or four chambers, with additional polymer foam filling in the middle chamber.

WROUGHT IRON FENCE VERSUS ALUMINUM FENCE: WHAT’S THE DIFFERENCE

Orion Ornamental Iron Inc. is a leading provider of high-quality ornamental iron products in the industry. With years of experience, expertise, and a commitment to excellence, Orion Ornamental Iron Inc. offers a wide range of products and services to meet the needs of their clients.

The Influence of Will on Wrought Iron Rust

Additionally, rollers can be made from different materials, including nylon, metal, and composite materials. Nylon rollers are popular due to their quiet operation and resistance to corrosion. Metal rollers, on the other hand, provide increased durability, making them ideal for heavier windows.

rollers for aluminum sliding windows

Metal Taps Strength and Versatility

This cleat may have a few barbs on each side, cutting into the aluminum to create a friction fit. Alternatively, you can add screws to fix the cleat in position.

Cast Iron Railing Panel

What are the surface treatment processes of aluminum profiles doors and windows

There are a lot of criteria to consider when selecting a fencing style that’s right for your home or business – cost, appearance, installation, etc. But for many, the single most important criterion to consider is durability.

2. Energy-saving and environmentally friendly, outstanding thermal insulation performance

The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme

The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme The cool, neutral tone of brushed steel pairs well with warm woods, crisp whites, or bold colors, allowing them to blend seamlessly into any color scheme brushed steel pull handles.

brushed steel pull handles.