casting dredge pump part factories

Latest articles

Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read MoreAs wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read MoreAs this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read MoreWZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read MoreIf you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read More>Slurry Pump VS Mud Pump

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read More>Slurry Pump

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read MoreFrom an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read MoreSubmersible Slurry Pump

casting dredge pump part factories...

casting dredge pump part factories 【casting dredge pump part factories】

Read More

Popular articles

- The design of the slurry pump is critical to ensure that the abrasive and often corrosive aspects of the slurry do not damage the impeller. In addition, slurries and sludges may contain large amounts of unforeseen solids, which will inevitably clog many types of pumps. Since most centrifugal pump impellers have very tight tolerances on the worm gear, the abrasive (and sometimes corrosive) nature of the slurry will quickly wear down the worm gear and destroy the tolerances. In turn, this causes the pump to lose suction. This can lead to extensive downtime of the slurry pump, as well as expensive maintenance and spare parts.

- The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

- Slurry Pump

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

- Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

- If a centrifugal pump, is the design and material used to construct the impeller suitable for pumping slurries?

Latest articles

-

Dry Installation

-

Slurry Pump

-

Mud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

-

How to choose a slurry pump?

-

Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

-

The terms flushing and quench, often seem to be confused or misused when discussing seal support schemes for , slurry pumps, . As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

Links

- In conclusion, the humble 32mm drill bit serves as a cornerstone in many crafters' and contractors' toolkits. Its versatility makes it an instrument for precision and efficiency, capable of handling a variety of materials with ease. Whether you're a seasoned professional or an enthusiastic beginner, investing in a quality 32mm drill bit is a decision you won't regret. So, the next time you're about to embark on a project that calls for accuracy and strength, remember that the 32mm drill bit could very well be your most reliable partner in achieving success.

Standard Colors stocked are Light Gray, Green and Yellow in sizes:

- Fiberglass trough covers are essential components in the construction and maintenance of various industrial facilities, including water treatment plants, chemical processing plants, and agricultural operations. These covers provide protection for troughs and channels, preventing debris and contaminants from entering and obstructing the flow of liquids.

- The Significance of FRP Water Tanks in Modern Infrastructure

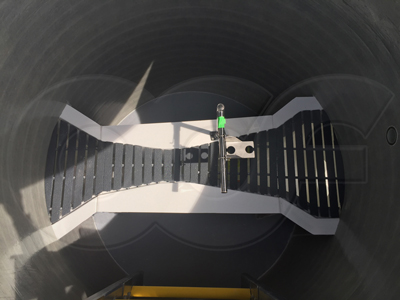

FIBERGLASS COVERED GRATING

- Moreover, the chemical resistance of fiberglass tanks extends to a multitude of chemicals, including acids, alkalis, solvents, and salts. This versatility allows them to be used in industries such as pharmaceuticals, petrochemicals, wastewater treatment, agriculture, and food processing, where the safe storage of diverse chemicals is paramount.

- In conclusion, the integration of fiberglass in sewage treatment processes is a testament to the marriage of technology and environmental stewardship. Its unique attributes have proven to be a game-changer, enhancing the effectiveness and sustainability of wastewater management systems. As we continue to grapple with the challenges of urbanization and environmental protection, the role of fiberglass in sewage treatment will undoubtedly grow in significance, shaping a cleaner and more sustainable future.

- Moreover, the lightweight nature of fiberglass tanks is another key feature that sets them apart. Despite their strength, they are significantly lighter than steel or concrete alternatives, simplifying transportation and installation. This reduces overall project costs and minimizes the need for heavy machinery during setup, making it a popular choice for remote or challenging locations.

- 2. Commercial Boilers In commercial settings, fiberglass insulation tanks are used to store hot water for boilers, which are used to provide heating and hot water to buildings.

- The Role of Fiberglass in Sewage Treatment

Fiberglass Structural Shapes:

- In conclusion, tungsten carbide button bits are a game-changer in the world of drilling. Their exceptional durability, cutting ability, and versatility make them an invaluable tool for anyone involved in the mining and construction industries. With their ability to increase efficiency, reduce costs, and improve safety, these bits are sure to become a staple in any drilling operation.

Water and Wastewater Treatment: Used in water and wastewater treatment facilities due to its corrosion resistance and slip resistance. NSF-61-certified materials permit use in drinking water facilities.

Gratings & Covers

Specialty Steel isn’t just a molded FRP grating supplier — we also fabricate our products so you can rest assured that you get the best product customized to your specific application. We take great pride in quality control for our products. If you would prefer to fabricate your molded grating, refer to the following procedures:

frp water tank. From small domestic units to large-scale industrial installations, FRP water tanks can be tailored to meet specific requirements, making them a versatile solution for various sectors, including agriculture, residential complexes, and industrial plants.

frp water tank. From small domestic units to large-scale industrial installations, FRP water tanks can be tailored to meet specific requirements, making them a versatile solution for various sectors, including agriculture, residential complexes, and industrial plants. Its simple and user-friendly design allows operators to quickly disassemble and reassemble the drill for regular maintenance, reducing downtime and increasing uptime Its simple and user-friendly design allows operators to quickly disassemble and reassemble the drill for regular maintenance, reducing downtime and increasing uptime

Its simple and user-friendly design allows operators to quickly disassemble and reassemble the drill for regular maintenance, reducing downtime and increasing uptime Its simple and user-friendly design allows operators to quickly disassemble and reassemble the drill for regular maintenance, reducing downtime and increasing uptime yt28 rock drill. This ensures that the drill remains in top condition and performs optimally throughout its lifespan.

yt28 rock drill. This ensures that the drill remains in top condition and performs optimally throughout its lifespan.we carry a wide range of FRP products and systems designed to give you maximum choice. In the case of our reinforced grating, we offer two major product lines: molded grating and pultruded grating. Each manufacturing method has its own advantages and results in products with their own mix of performance and durability advantages. If you’re hesitating between molded versus pultruded grating, our experienced team can help you make that decision by highlighting the benefits of each.

Four Types Fiberglass Gratings

fire retardant fiberglass. Its flexibility allows it to be easily shaped and cut to fit specific requirements, making it ideal for custom installations in tight spaces or unusual shapes.